Double-U type buffering support and manufacturing method thereof

A production method, U-shaped technology, applied in the direction of shock absorber, spring/shock absorber, elastic shock absorber, etc., can solve the problems of small compression stroke, poor compressive bearing capacity, and non-reusable use, so as to increase the impact The effect of bearing capacity, simple manufacture, convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

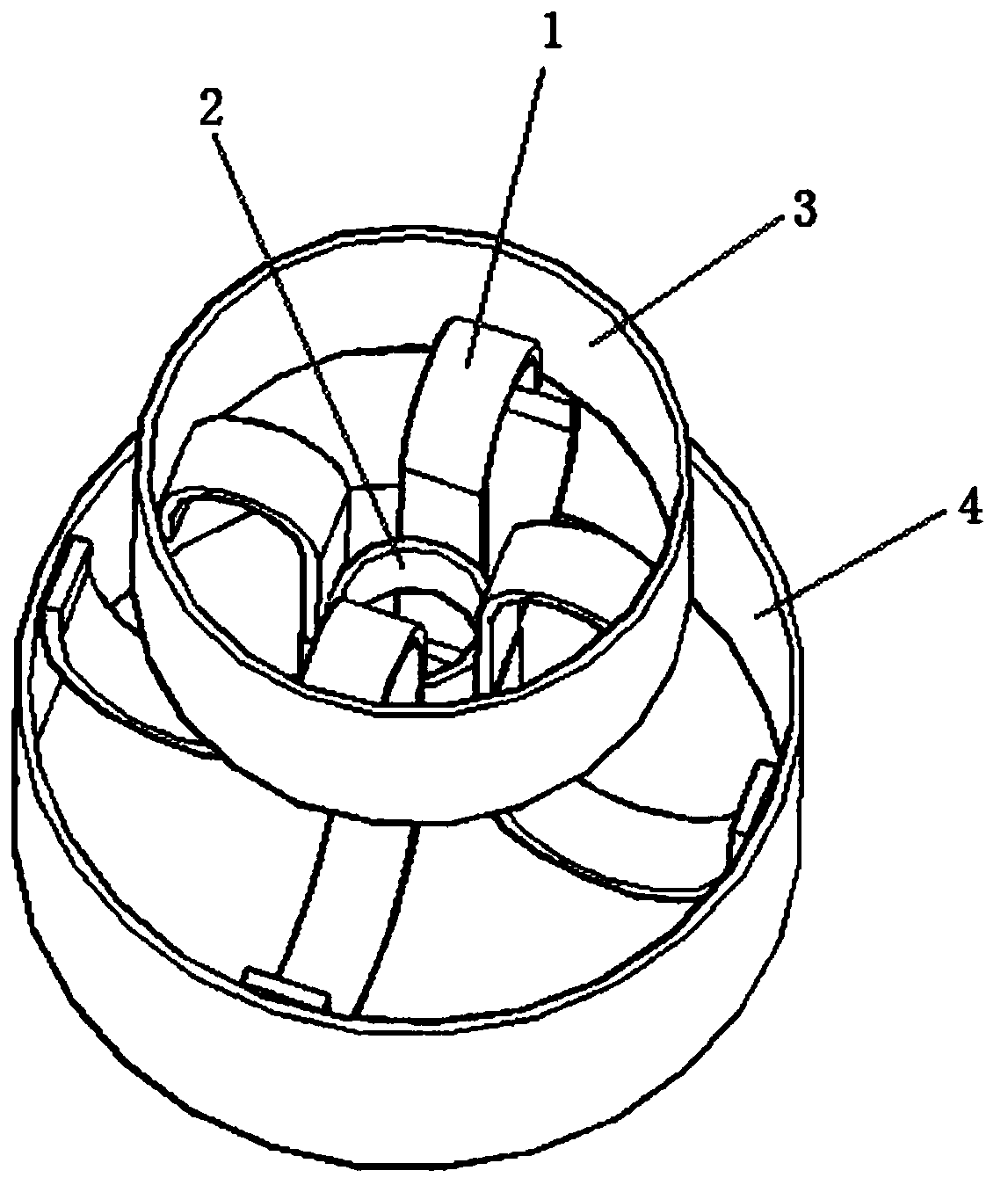

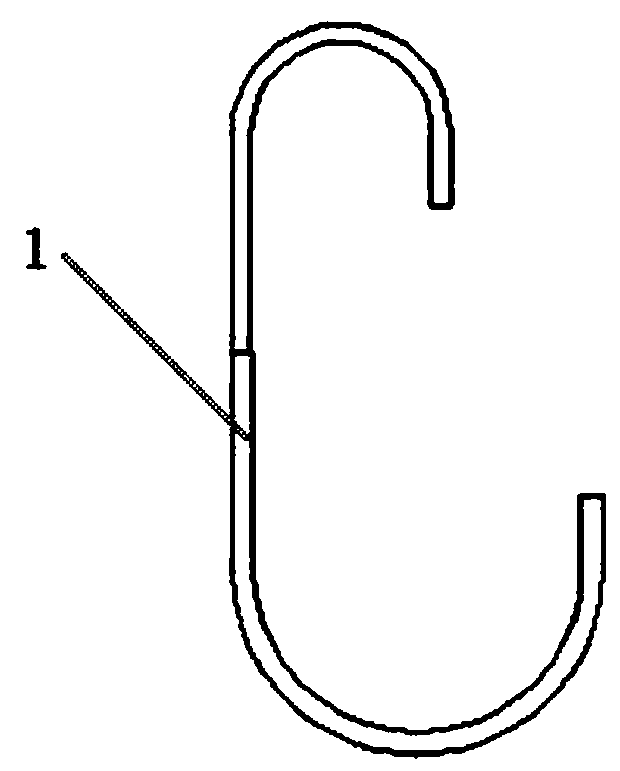

[0034] A double U-shaped cushioning support of the present invention, such as figure 1 As shown, it includes a double U-shaped member 1, a first ring 2, a second ring 3 and a third ring 4, such as figure 2 As shown, the double U-shaped member 1 includes a U-shaped member and an inverted U-shaped member, the width of the open end of the inverted U-shaped member is smaller than the width of the open end of the U-shaped member, and the thickness of the inverted U-shaped member is smaller than the thickness of the U-shaped member. One open end of the U-shaped member is connected to one open end of the inverted U-shaped member. The length of the connection side of the double U-shaped member 1 is greater than the sum of the lengths of the open sides. The opening sides of the double U-shaped member 1 are located on the same side, and the double U-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com