Automobile tire valve assembly

A technology for automobile tires and valves, which is applied in the direction of tire inflation valves, tire parts, vehicle parts, etc., and can solve the problem of decreased sealing performance of tires, tight sealing design, and easy sealing problems at the contact between the core and the nozzle, etc. problems, to achieve the effect of reducing tire inflation frequency, reasonable and reliable structure, and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

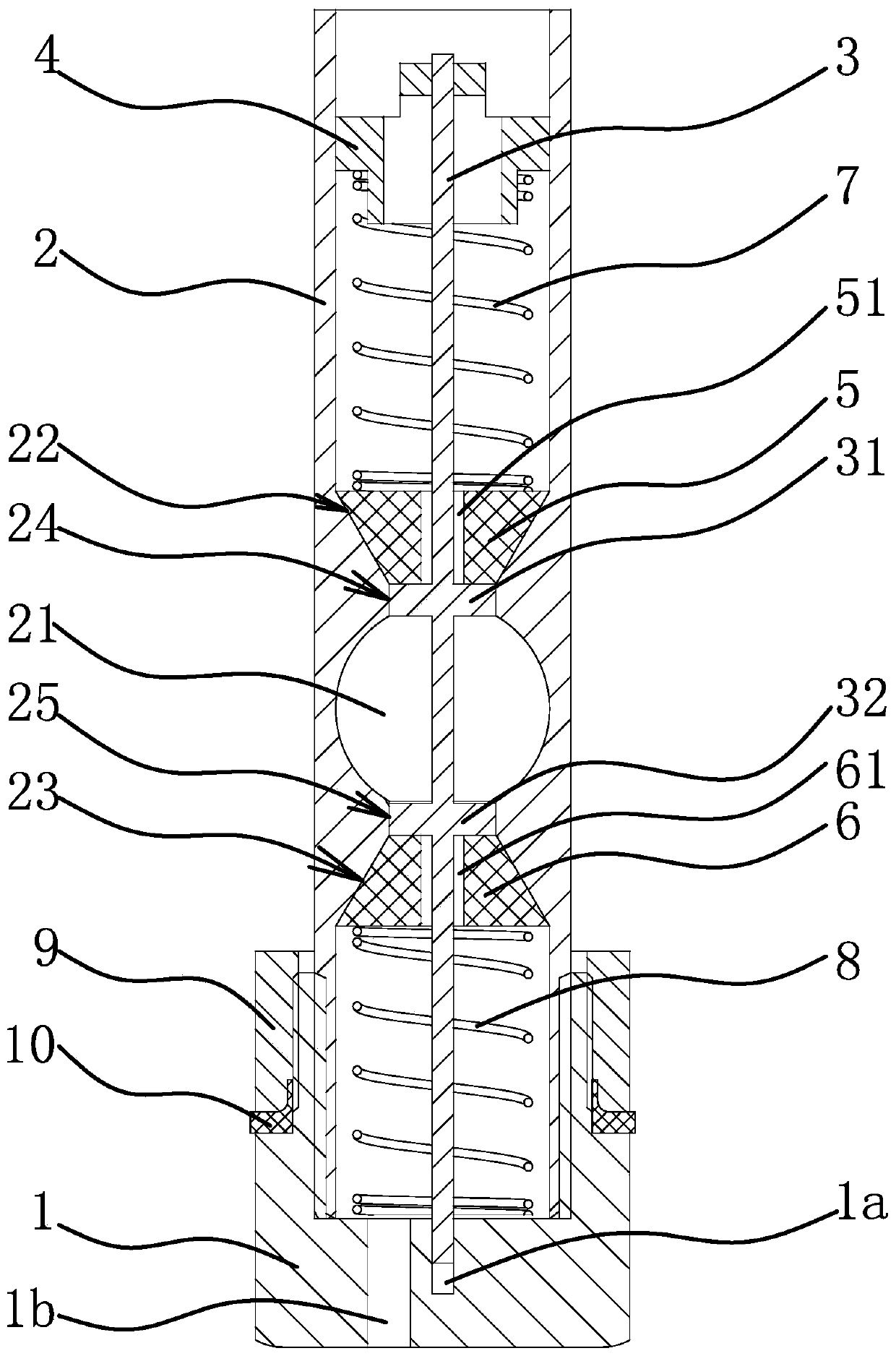

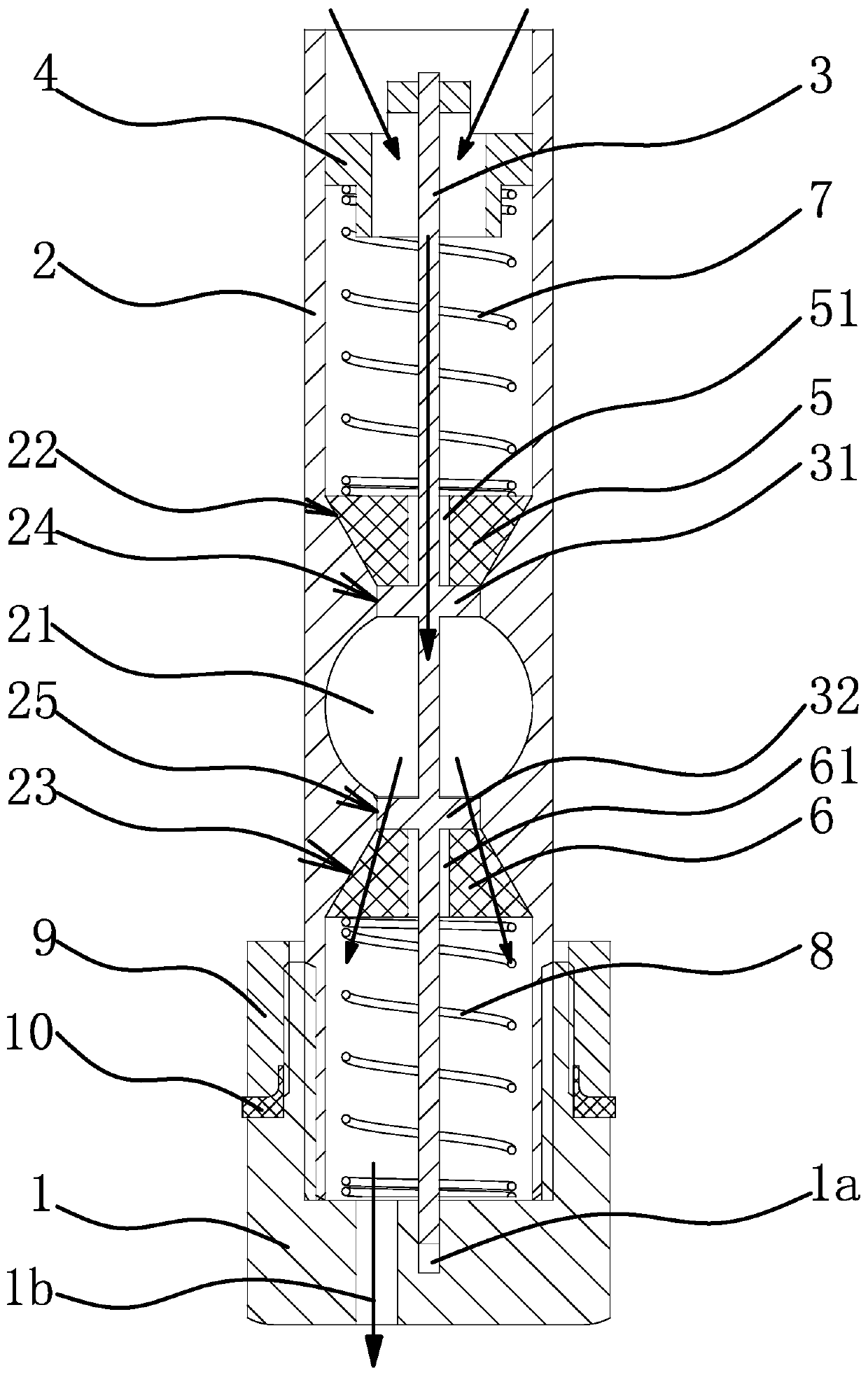

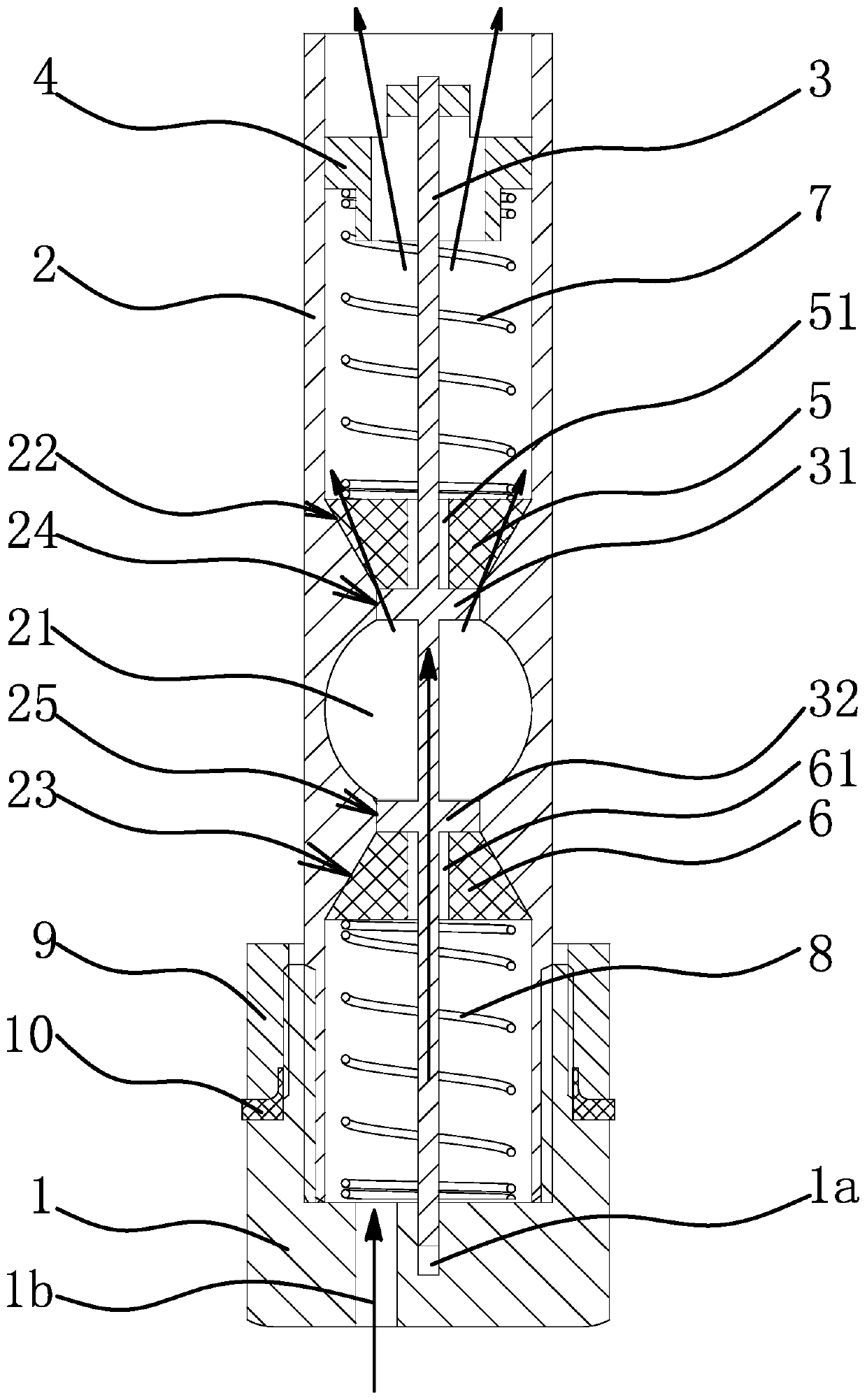

[0023] Specifically, such as figure 1 As shown, the tire valve assembly of the present automobile includes a base 1, a shell sleeve 2, a core rod 3 slidingly fitted with the shell sleeve 2, and a nut 4 fixed in the upper end of the shell sleeve 2. Wherein, the base 1 is provided with a blind hole 1a, and the core rod 3 penetrates the blind hole 1a and is slidably connected with the blind hole 1a. The base 1 also has a channel 1b communicating with the air cavity in the tire. The lower end of the shell sleeve 2 is threadedly connected with the base 1, and a lock nut 9 is threaded on the outside of the base 1, and a sealing ring 10 is provided between the lower end of the lock nut 9 and the base 1.

[0024] At the same time, the casing 2 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com