Fixed-frequency variable flow condensation unit system

A condensing unit and variable flow technology, which is applied in the direction of refrigerators, refrigeration components, compressors, etc., can solve the problems of difficult return of lubricating oil to the compressor, slow flow rate of refrigerant, interference, etc., to avoid the problem of high point interference and additional noise , avoid lubricating oil problems, and solve the effect of frequency conversion interference problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

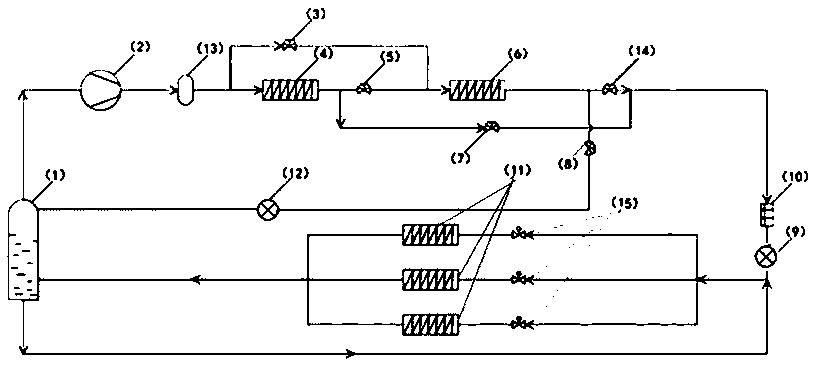

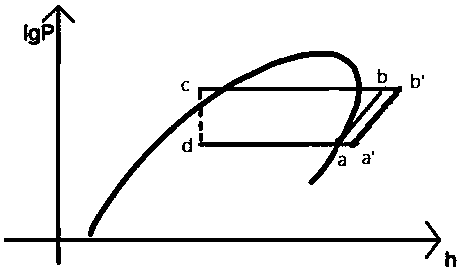

[0020] Example 1 Full load operation

[0021] refer to figure 2 , when the system is running at full load, the first flow regulating valve 3 is closed, the first solenoid valve 5 and the fourth solenoid valve 14 are opened, the second solenoid valve 7 and the third solenoid valve 8 are closed, the bypass refrigerant passage is closed, all The refrigerant all enters the evaporator group 11 for refrigeration. The refrigerant passage is as follows: the refrigerant gas enters the condenser 4 to condense, and then enters the subcooler 6 for recooling, and the recooled refrigerant enters the drying filter 10 and the first throttle valve 9, and then flows through the flow regulating valve 15 to divert into evaporation The evaporator group 11 evaporates and refrigerates, and then enters the gas-liquid separator 1. The separated gas enters the compressor 2 and the oil separator 13 and returns to the condenser 4. The separated liquid enters the suction port of the evaporator group 11,...

Embodiment 2

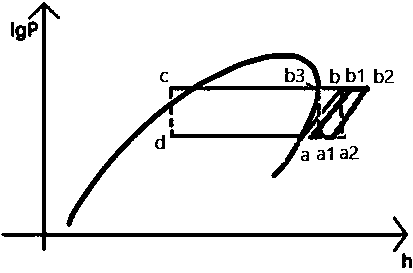

[0022] Example 2 Bypass refrigerant cooling to saturated gas state

[0023] refer to image 3 , when the partial load of the system is adjusted, the first solenoid valve 5 and the fourth solenoid valve 14 are closed, the second solenoid valve 7 and the third solenoid valve 8 are opened, and the first flow regulating valve 3 is opened. The refrigerant is discharged from the compressor 2 and passes through the oil separator 3, and the refrigerant is divided into two paths. One of the refrigerants enters the condenser 4 to condense, passes through the second solenoid valve 7, the dry filter 10, and the first throttle valve 9 to throttle, and after the second flow regulating valve 15, it diverts into the evaporator group 11 for cooling, and enters the gas-liquid Separator 1. Another path of refrigerant passes through the first flow regulating valve 3 , the subcooler 6 , the third solenoid valve 8 , and the second throttle valve 12 , and enters the gas-liquid separator 1 . After...

Embodiment 3

[0024] Example 3 Bypass refrigerant cooling to two-phase region

[0025] refer to Figure 4 , when the partial load of the system is adjusted, the first solenoid valve 5 and the fourth solenoid valve 14 are closed, the second solenoid valve 7 and the third solenoid valve 8 are opened, and the first flow regulating valve 3 is opened. The refrigerant is discharged from the compressor 2 and passes through the oil separator 3, and the refrigerant is divided into two paths. One of the refrigerants enters the condenser 4 to condense, passes through the second electromagnetic valve 7, the drier filter 10, the first throttle valve 9 to throttle, and after the second flow regulating valve 15, it is diverted into the evaporator group 11 for cooling, and enters the gas Liquid separator 1. Another path of refrigerant passes through the first flow regulating valve 3 , the subcooler 6 , the third solenoid valve 8 , and the second throttle valve 12 , and enters the gas-liquid separator 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com