Liquid-separating mechanism with uniform liquid-separating function, installation method thereof, and air-conditioning system

An installation method and liquid separation technology, which are used in refrigerators, mechanical equipment, refrigeration and liquefaction, etc., can solve the problem that the liquid distribution head cannot evenly distribute liquid, and achieve the effect of overcoming the large difference in the dryness of the refrigerant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

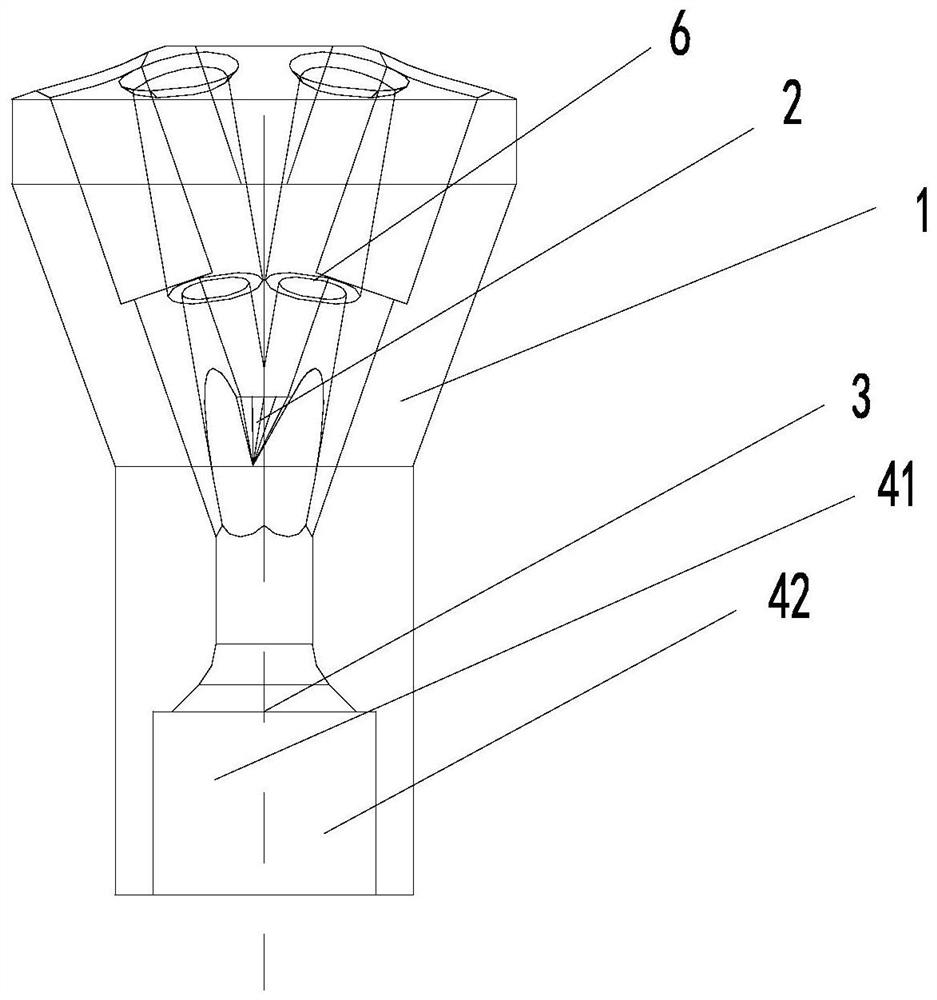

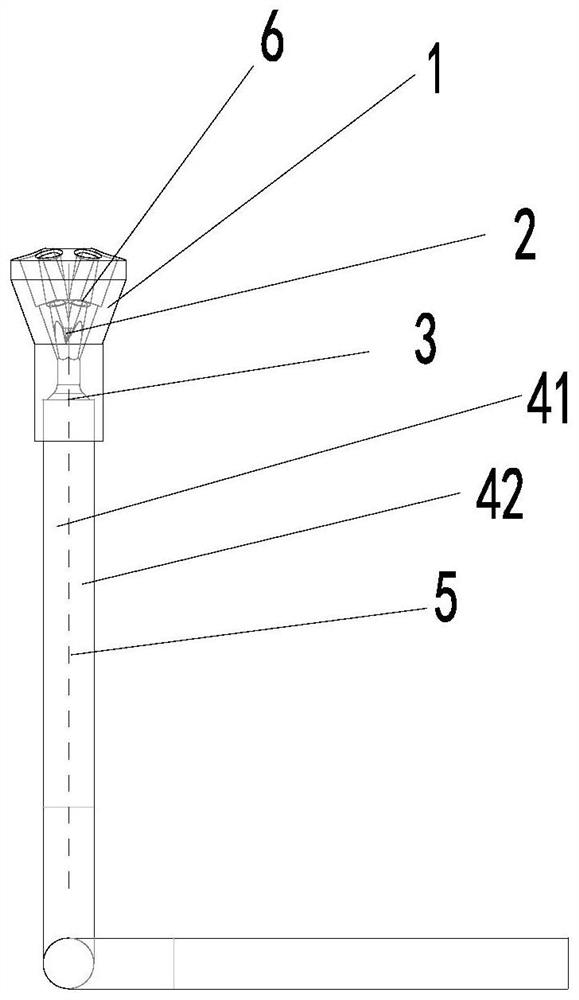

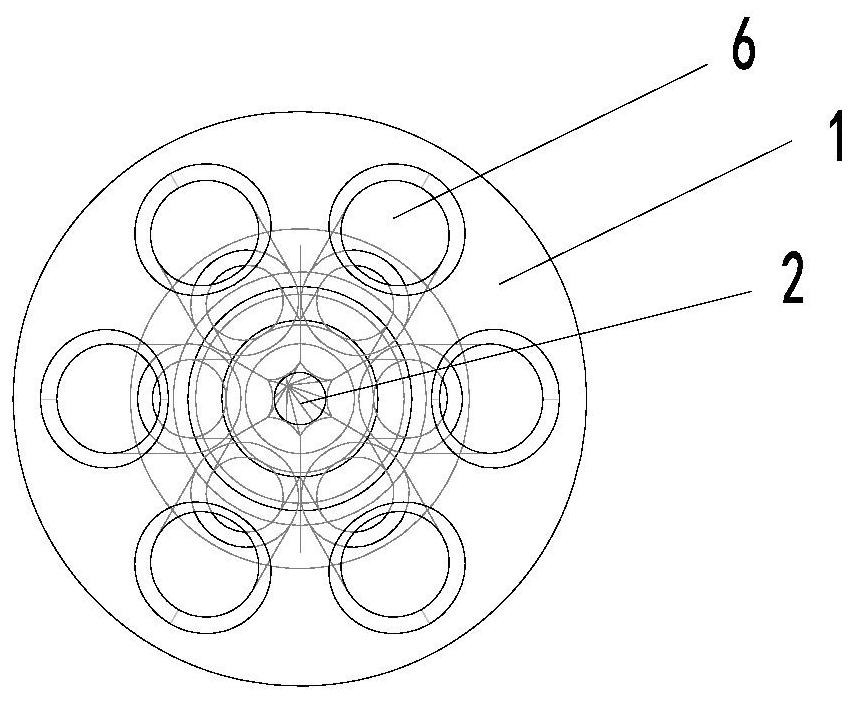

[0031] The process of comparing the dispensing effect of the liquid dispenser head a of the prior art with the liquid dispenser head b of the present application is as follows:

[0032] A liquid inlet pipe 5 with a 90° bend is connected to the liquid inlet 3 of the liquid dispenser head a and the liquid dispenser head b, wherein the apex of the split tip 2 of the liquid dispenser head 2 is moved away from the liquid inlet The direction of the liquid inlet direction of the tube 5 deviates by 0.7mm;

[0033] Keep the size of other parts, grid topology parameters and calculation process on the liquid head a and liquid head b completely consistent;

[0034] And set the inlet parameters of dispenser head a and dispenser head b as follows:

[0035] The dryness of the refrigerant inlet is 0.2; the inlet pressure is 1.15MPa; the inlet flow is 0.0528kg / s;

[0036] Finally, the results of Table 1 and Table 2 are obtained

[0037] Table 1 Distribution of refrigerant flow rate in each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com