Intelligent opposite-lifting plant protection spraying robot

A robot and plant protection technology, which is applied in the direction of instruments, injection devices, satellite radio beacon positioning systems, etc., can solve problems such as poor accuracy, physical health injuries of operators, pesticide and water utilization, and low operating efficiency, so as to improve Efficiency and quality, the effect of ensuring health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

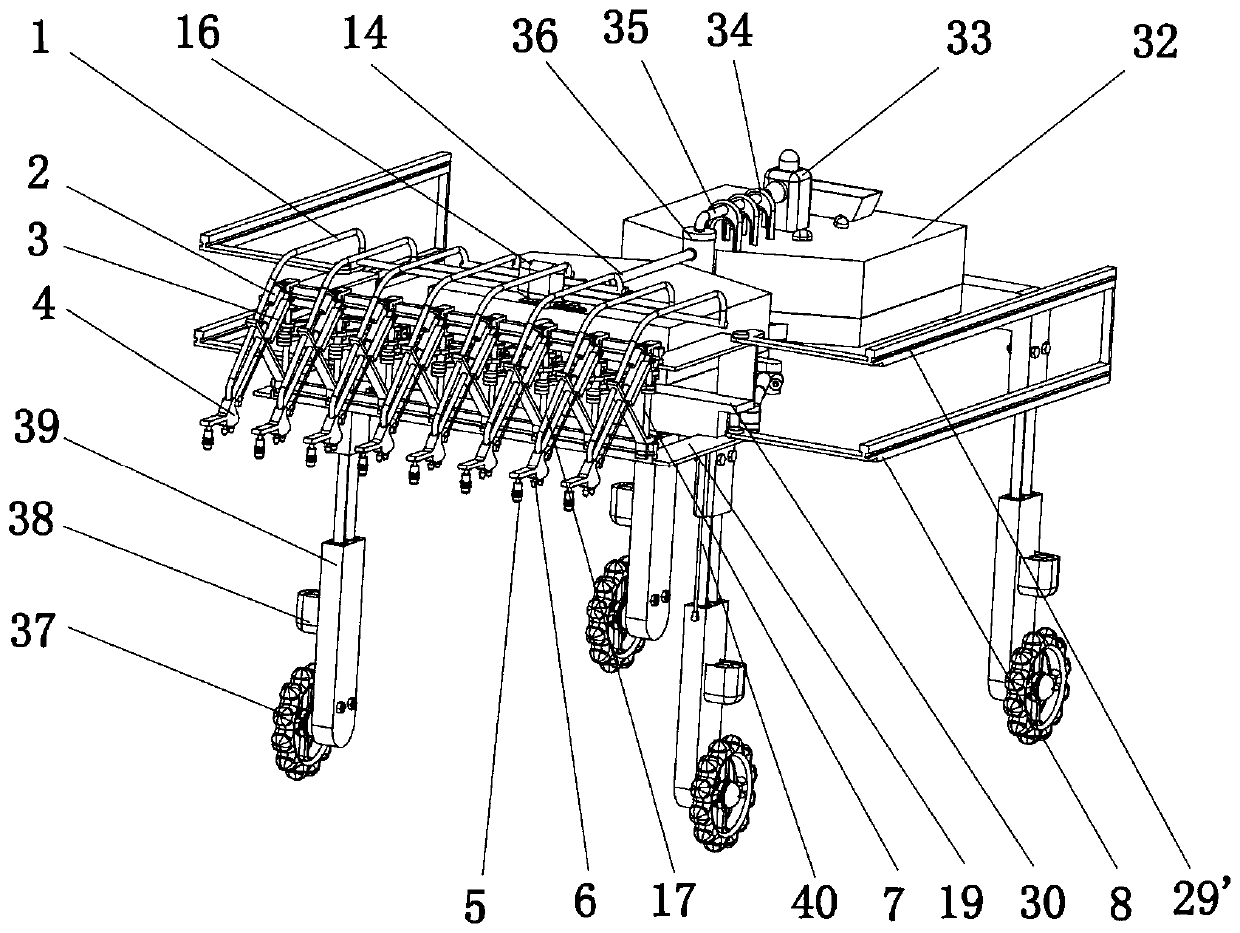

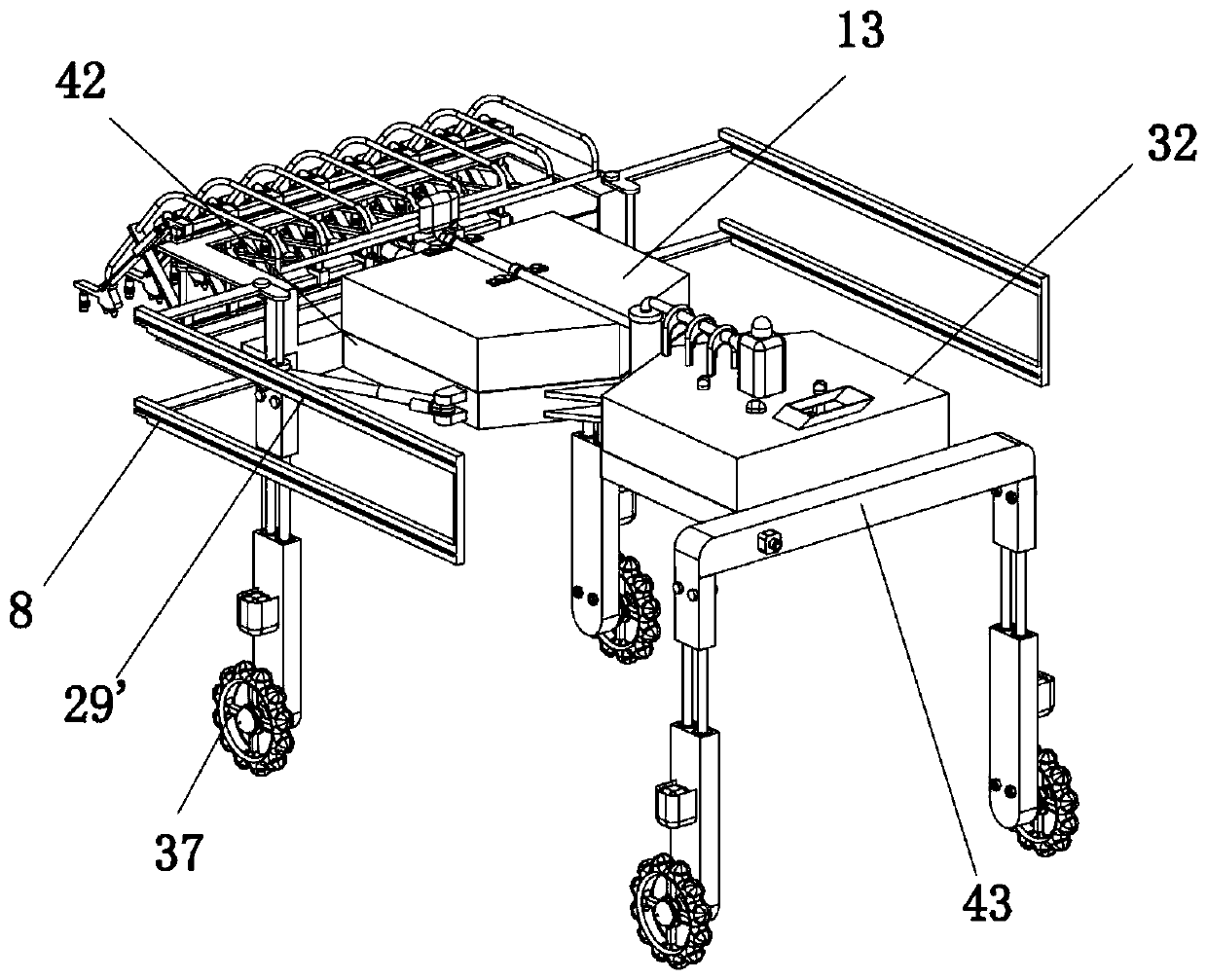

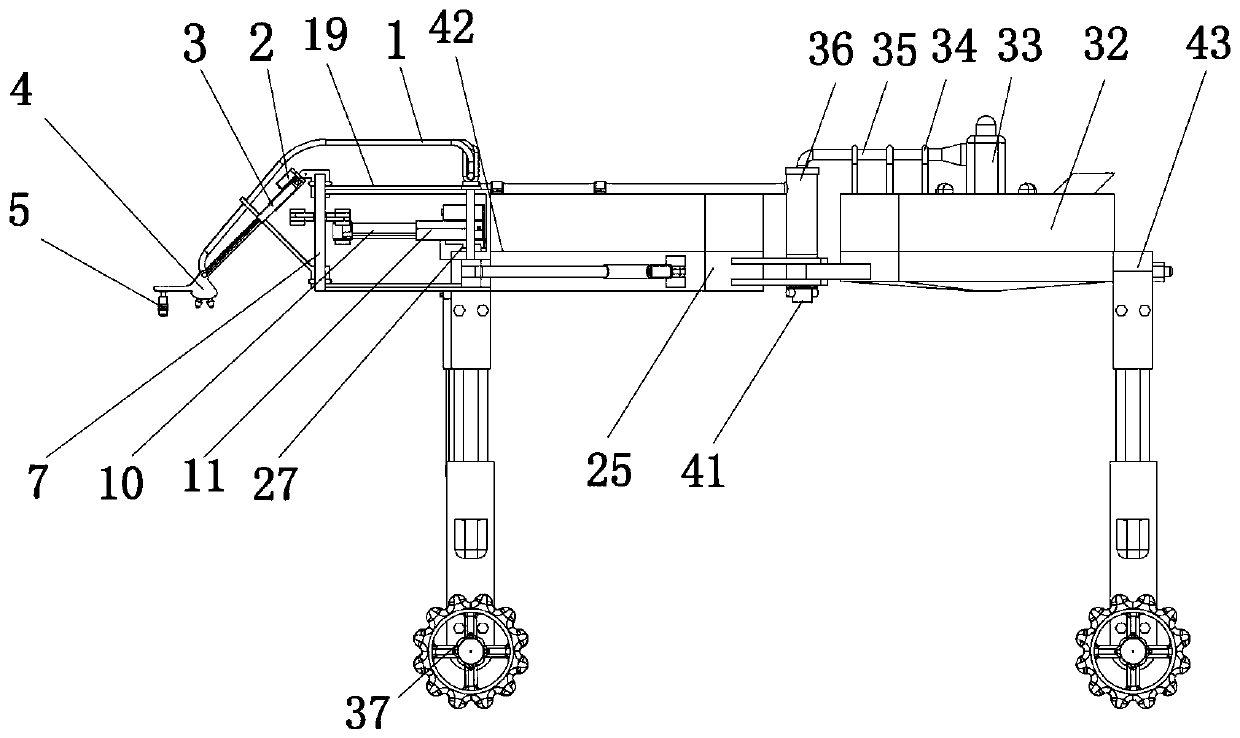

[0024] The intelligent counter-lifting plant protection spray robot of this embodiment is such as Figure 1 to Figure 4 As shown, the feasible frame 25 is composed of a front frame 42 and a rear frame 43 hinged by a frame connecting shaft 41, and is used to form a structural frame of the intelligent counter-profiling lifting device, which carries all the component modules. The front bracket 42 and the rear bracket 43 are respectively supported on the body lifting rod 40 inserted into the lower support leg 37 by supporting on both sides, and a roller 39 driven by a driving motor 38 is installed at the bottom.

[0025] The rear bracket 43 supports liquid storage facilities, including a hydraulic pump 33 located on the rear cover 32, and a liquid medicine output tube 35 positioned by a transport tube fixing frame 34. The hydraulic pump 33 passes through the liquid medicine output tube 35 and is connected to the machine. The coaxial hydraulic rotary joint 36 of the frame connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com