Mulching film laying device for crop cultivation

A technology for laying devices and crops is applied in the directions of fertilization devices, botanical equipment and methods, mixers with rotary stirring devices, etc. Quantitative addition of fertilizers, etc., to avoid falling down, good fixation function, and synchronization of adjustment positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

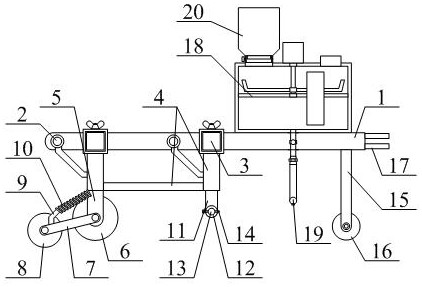

[0041] as attached figure 1 And attached figure 2 shown

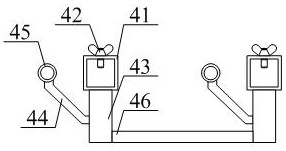

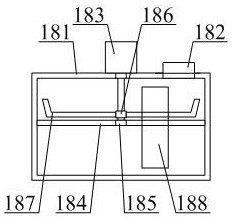

[0042]The invention provides a mulch laying device for crop cultivation, which includes a transverse connecting frame 1, a positioning rod 2, a rectangular positioning frame 3, an adjustable mounting frame structure 4, a rear wheel frame 5, a pressing wheel 6, a connecting plate 7, and soil covering Plow 8, L-shaped connecting frame 9, top spring 10, middle mounting frame 11, fixing ring 12, storage rod 13, positioning pin 14, front wheel frame 15, front moving wheel 16, clamping plate 17, fertilizer stirring Frame structure 18, humidification and fertilization frame structure 19 and fertilizer quantitative addition frame structure 20, the described positioning rod 2 is arranged on the left side of the rectangular positioning frame 3, and is welded on the front and rear sides of the transverse connecting frame 1 at the same time; the described rectangular positioning The frame 3 is arranged at the middle position and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com