Novel front exhaust steaming oven

An oven and steaming technology, which is applied in the field of steaming ovens, can solve problems such as condensed water accumulating in the door body, easily damaged steam pipes, and unreasonable structure of the steam exhaust system, so as to reduce the possibility of steam damage and avoid The effect of exhaust sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

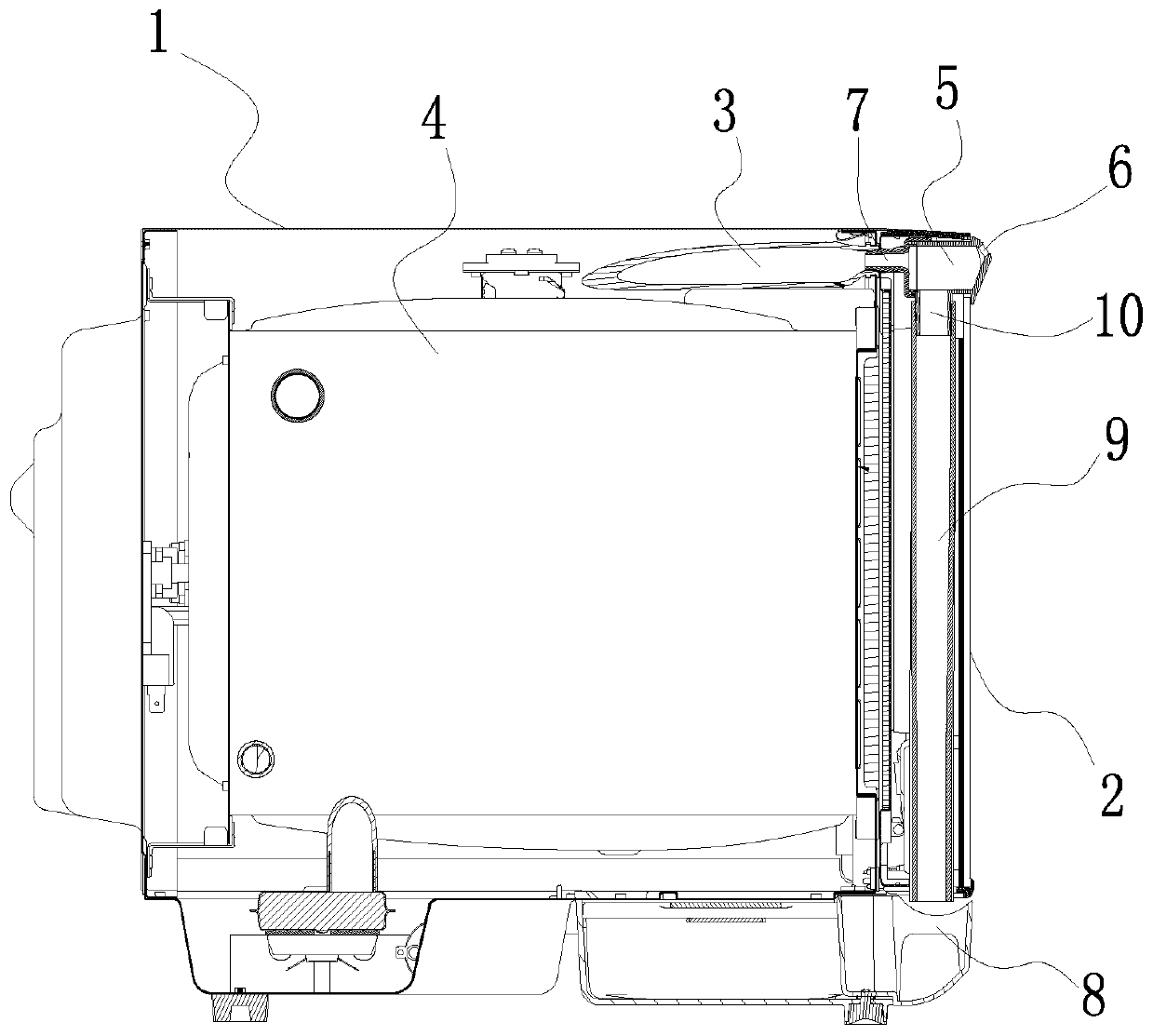

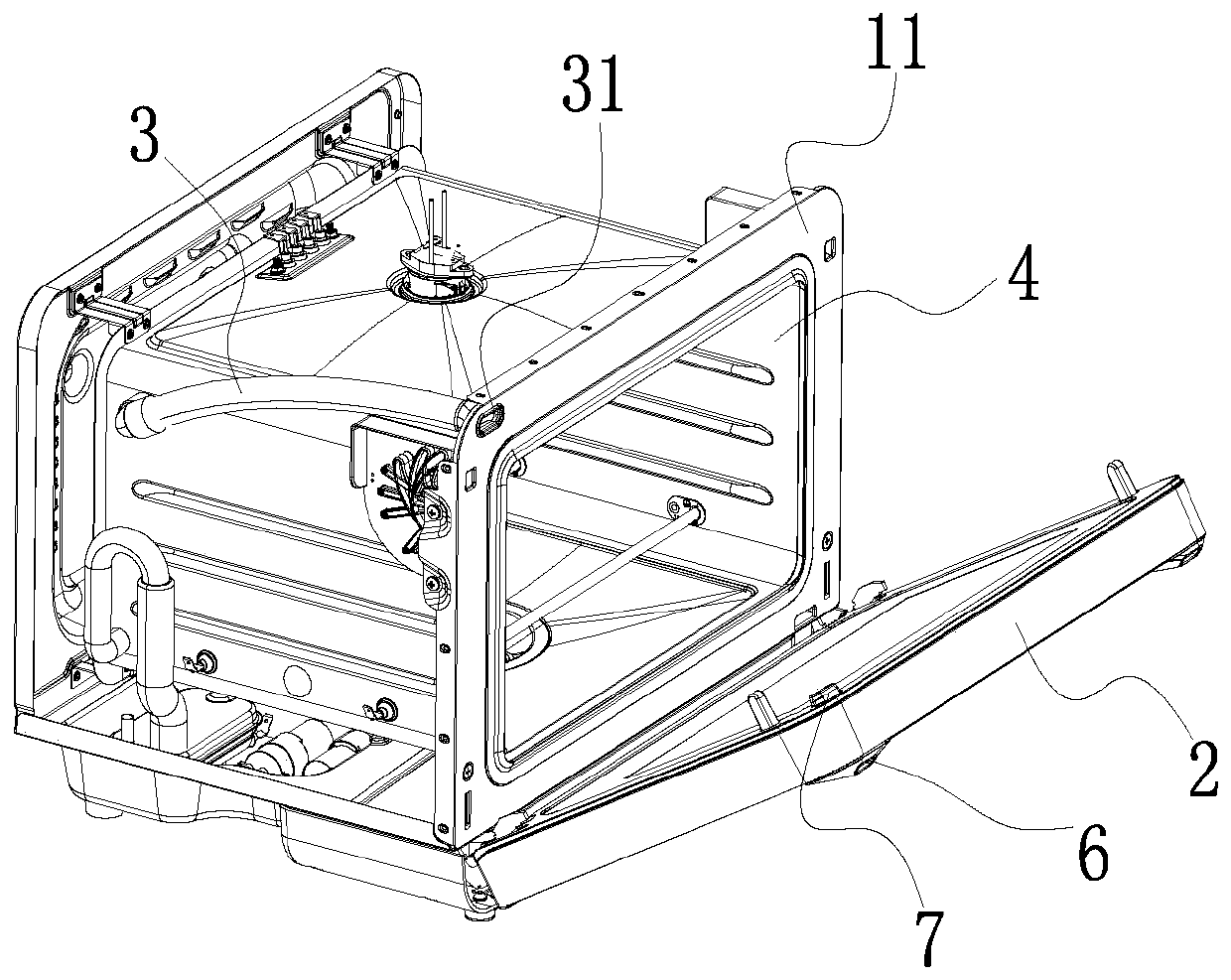

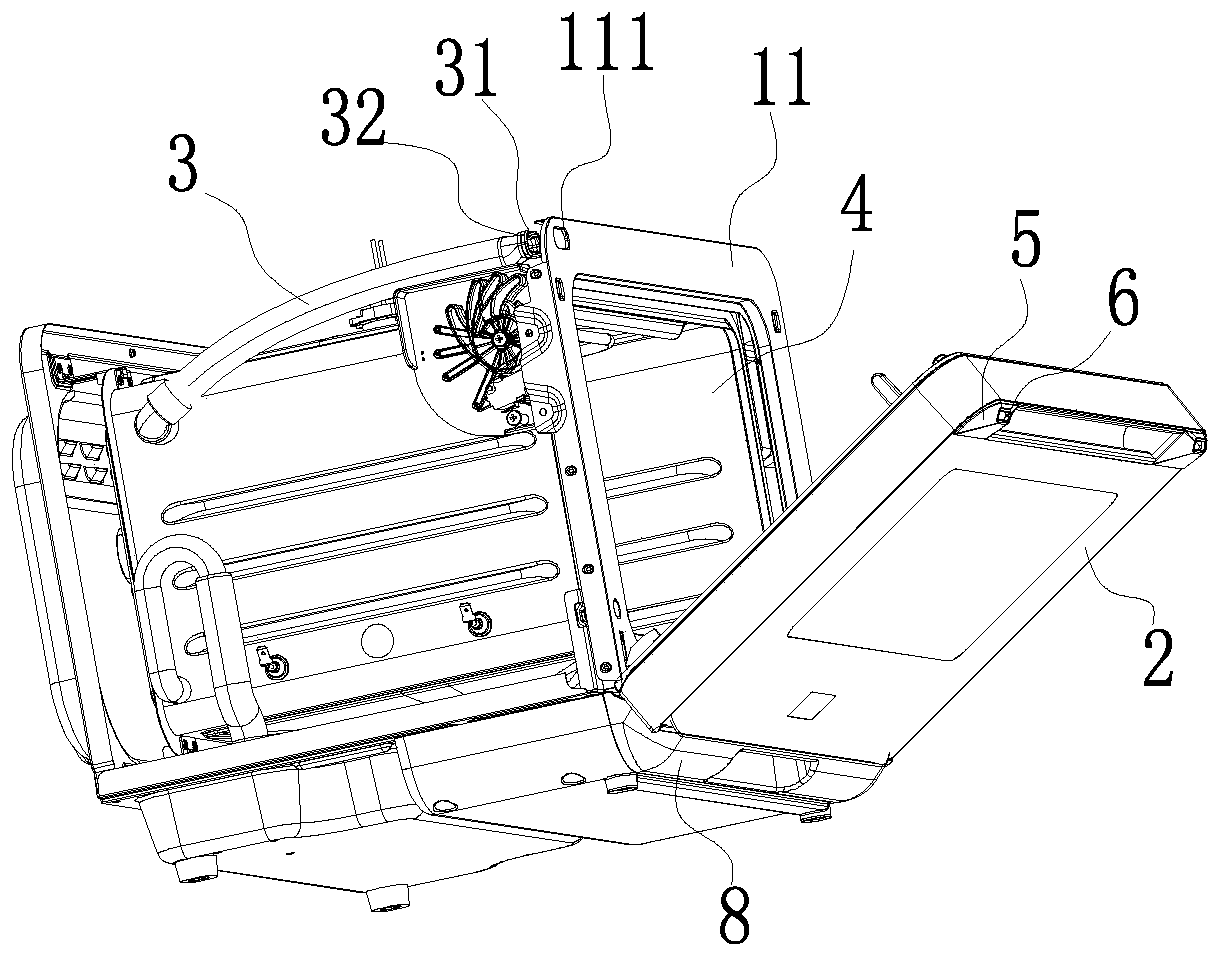

[0020] Please see Figure 1-3 , the application provides a new type of front row steaming oven, which includes a furnace body 1, a door body 2 and a steam pipe 3, the inlet end of the steam pipe 3 communicates with the inner cavity 4 of the furnace body 1, and the gas outlet end 31 is located on the front plate 11 of the furnace body 1, and the door body 2 is provided with an exhaust shell 5, and the exhaust shell 5 is provided with an air inlet and an exhaust port 6. When the door body 2 is closed, the The gas outlet 31 communicates with the air inlet, and the exhaust port 6 protrudes from the outer wall of the door body 2. Specifically, the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com