Plastic hook with high pressure resistance for fixing reinforcement mesh cage structure

A technology with high pressure resistance and reinforced mesh, which is applied in the direction of friction-clamped detachable fasteners, connecting components, manufacturing tools, etc., and can solve problems such as insufficient structural stability, mesh cage misalignment, and easy cracking , to achieve enhanced density, strong pressure resistance, and the effect of preventing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

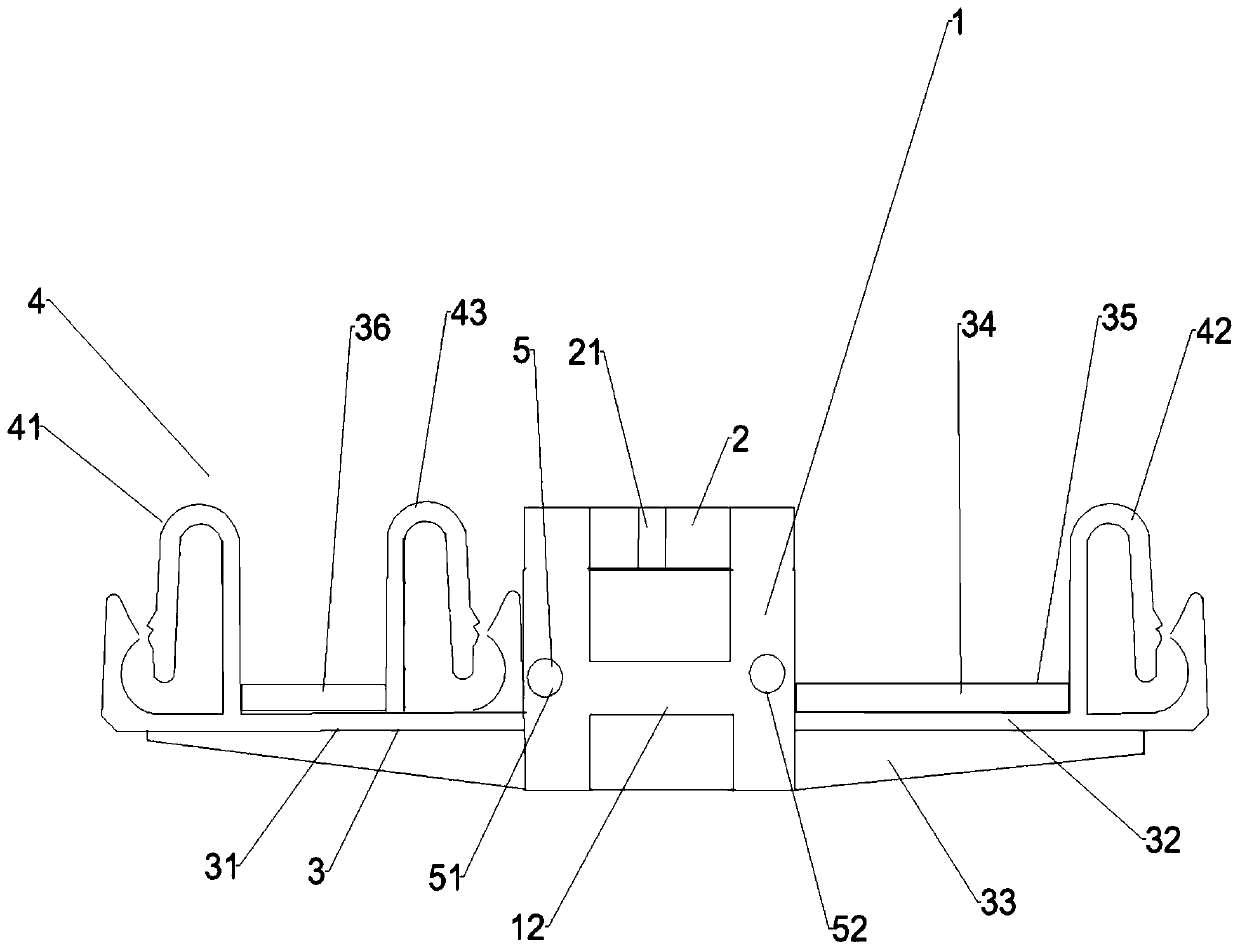

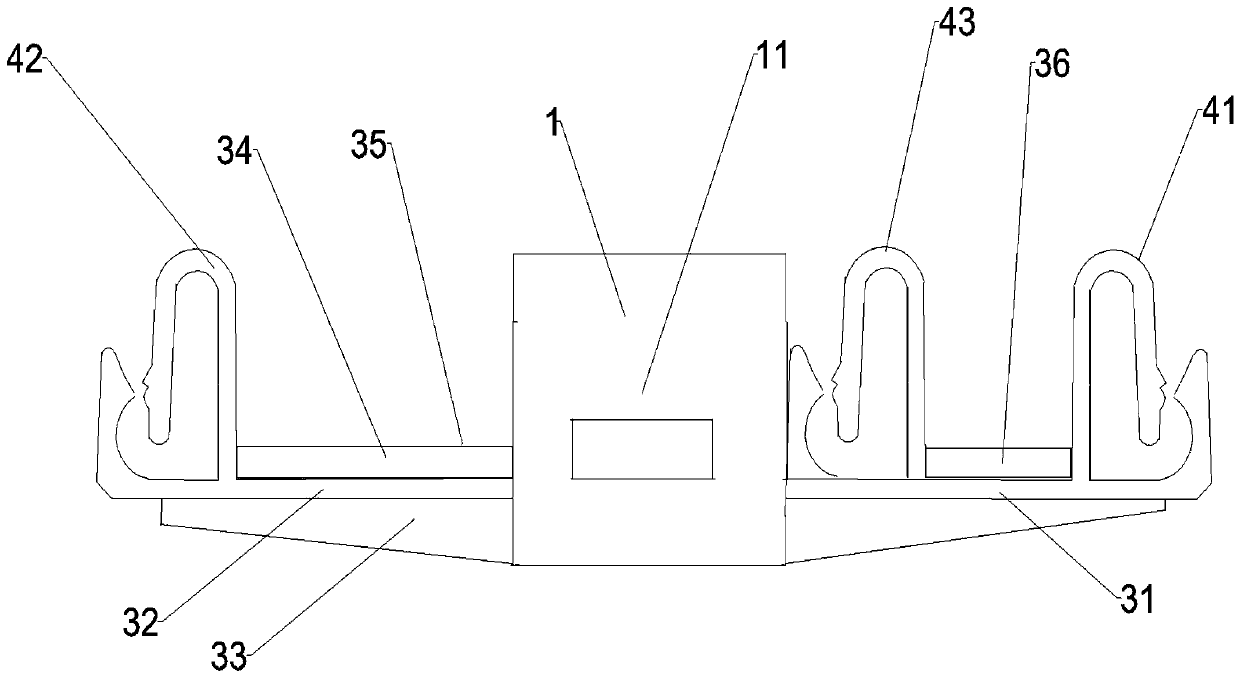

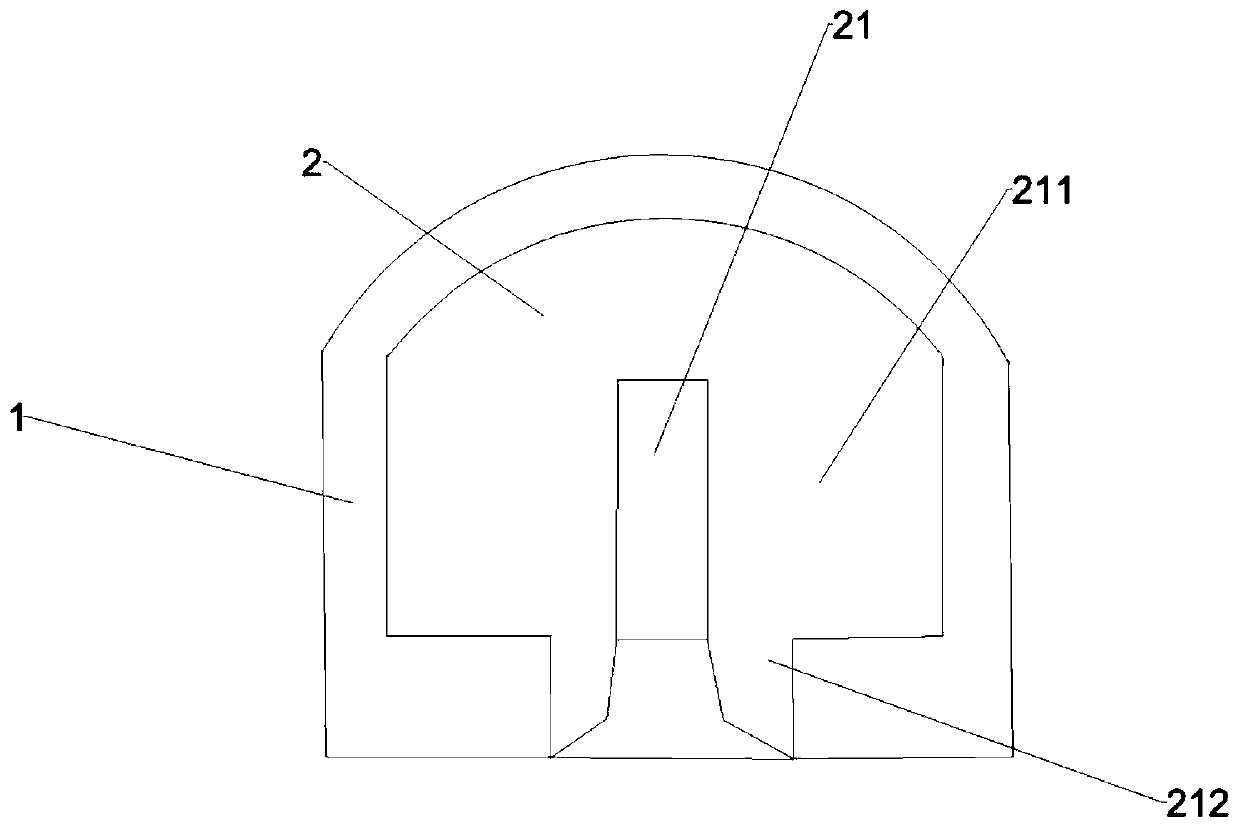

[0036] From figure 1 It can be seen that a plastic hook for fixing a reinforced mesh cage structure with high pressure resistance includes a jacket 1, a fixing plate 2, a fixing frame 3, and a fixing clip 4, and the fixing frame 3 includes a first fixing frame 31 and a second fixing frame 32. Both the first fixing frame 31 and the second fixing frame 32 are fixedly connected to the jacket 1. The fixing clip 4 includes a first fixing clip 41, a second fixing clip 42 and a third fixing clip 43. The first fixing clip 41 is fixedly connected At the free end of the first fixed frame 31, the second fixed clip 42 is fixedly connected to the free end of the second fixed frame 32, and the third fixed clip 43 is fixedly connected to the junction of the first fixed frame 31 and the jacket 1, Two capacity grooves 5 are arranged on the outer wall of the jacket 1, and the capacity grooves 5 are all located on the same horizontal plane. figure 2 Among them, the jacket 1 is a U-shaped jacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com