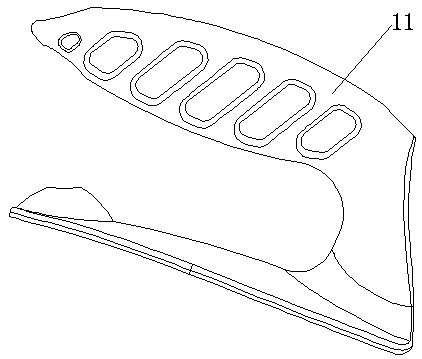

Lateral secondary core-pulling injection mould applied to coffee machine handle production

A secondary core-pulling and injection-mold technology, which is applied in the field of side core-pulling mechanisms, can solve the problem that the injection mold cannot be attached to the injection machine, etc., and achieve the effects of simple and low installation, low manufacturing cost, and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and embodiments.

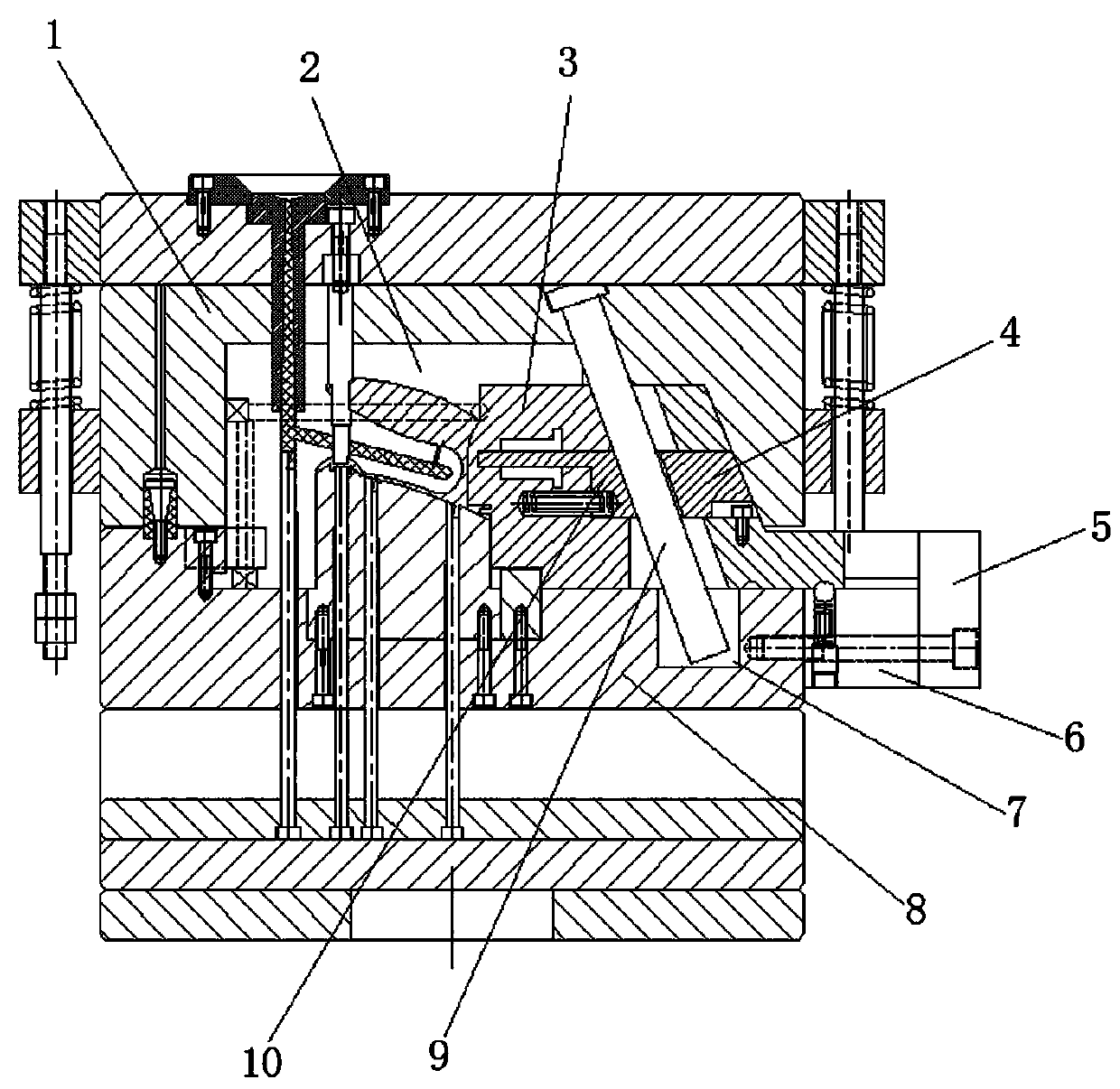

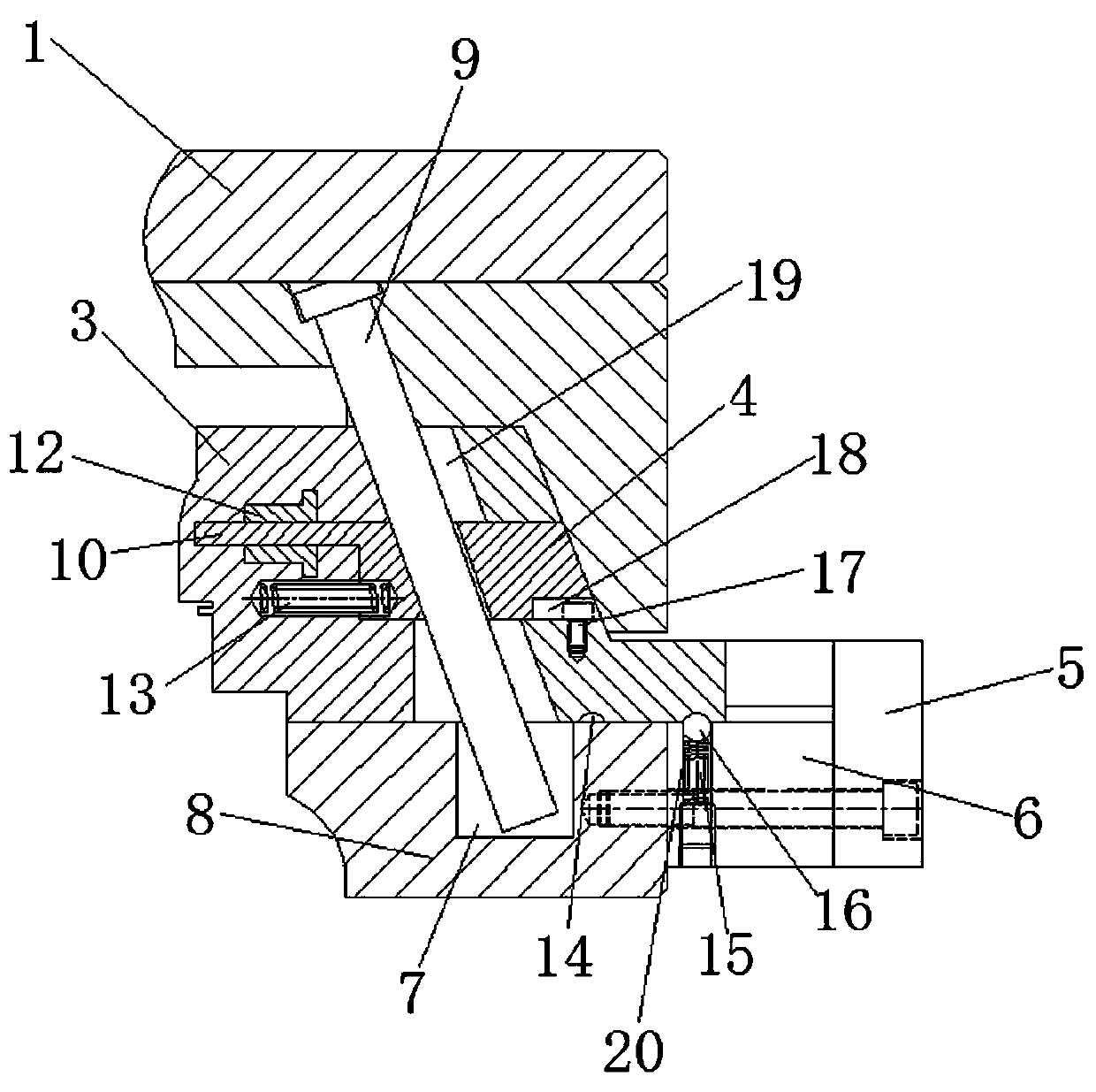

[0024] Such as figure 1 As shown, a lateral secondary core-pulling injection mold used in the production of coffee machine handles. The injection mold includes a movable mold 8 and a fixed mold 1. A molding cavity 2 is formed between the fixed mold 1 and the movable mold 8. The opening and closing directions of the mold are arranged along the up and down direction of the movable mold 8. The movable mold 8 is equipped with a lateral secondary core pulling mechanism. The secondary core pulling mechanism includes a side sliding block 3, a sliding block 10, a rear sliding block 4 and The inclined guide post 9, the side sliding block 3 is slidably mounted on the movable mold 8 along the left and right direction of the movable mold 8, and the side sliding block 3 extends into the molding cavity 2, and the top end of the inclined guide post 9 is installed on the fixed mold 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com