Rivet feeding device for wine box package riveting machine

A technology of a feeding device and a riveting machine, applied in the field of riveting equipment, can solve the problems of serious safety hazards, low work efficiency, easy to cause accidents, etc., and achieve the effects of reducing labor costs, stable work and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

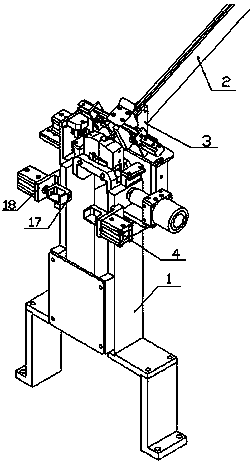

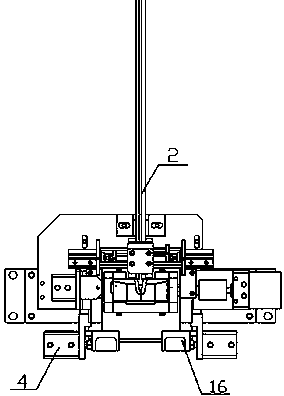

[0021] Such as figure 1 , 2 As shown, a rivet feeding device for a wine box packaging rivet machine includes a rivet splitting mechanism, a rivet turning and conveying mechanism, a clamping and separating mechanism, a rivet conveying frame, and a rivet flow channel. The rivet flow channel 2 is fixed on the On the rivet flow channel fixing seat 3, the rivet flow channel fixing seat 3 is hinged or welded on the rivet transmission frame 1, and the end of the rivet flow channel 2 is provided with a splitting mechanism. A clamping block 9 is arranged on the top, and the clamping block 9 can be connected with the clamping and separating mechanism under the drive of the rotating shaft 8. The clamping and separating mechanism is fixed on the rivet transmission frame 1 with bolts.

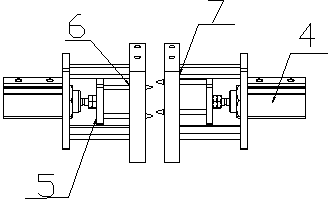

[0022] Such as image 3 Shown, the nail dividing mechanism comprises: cylinder 4, cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com