Construction method applied to lifting platform in elevator shaft in constructional engineering

A technology of lifting platform and construction method, which is applied in construction, building structure, scaffolding supported by house structure, etc., can solve the problems of time-consuming and laborious installation work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

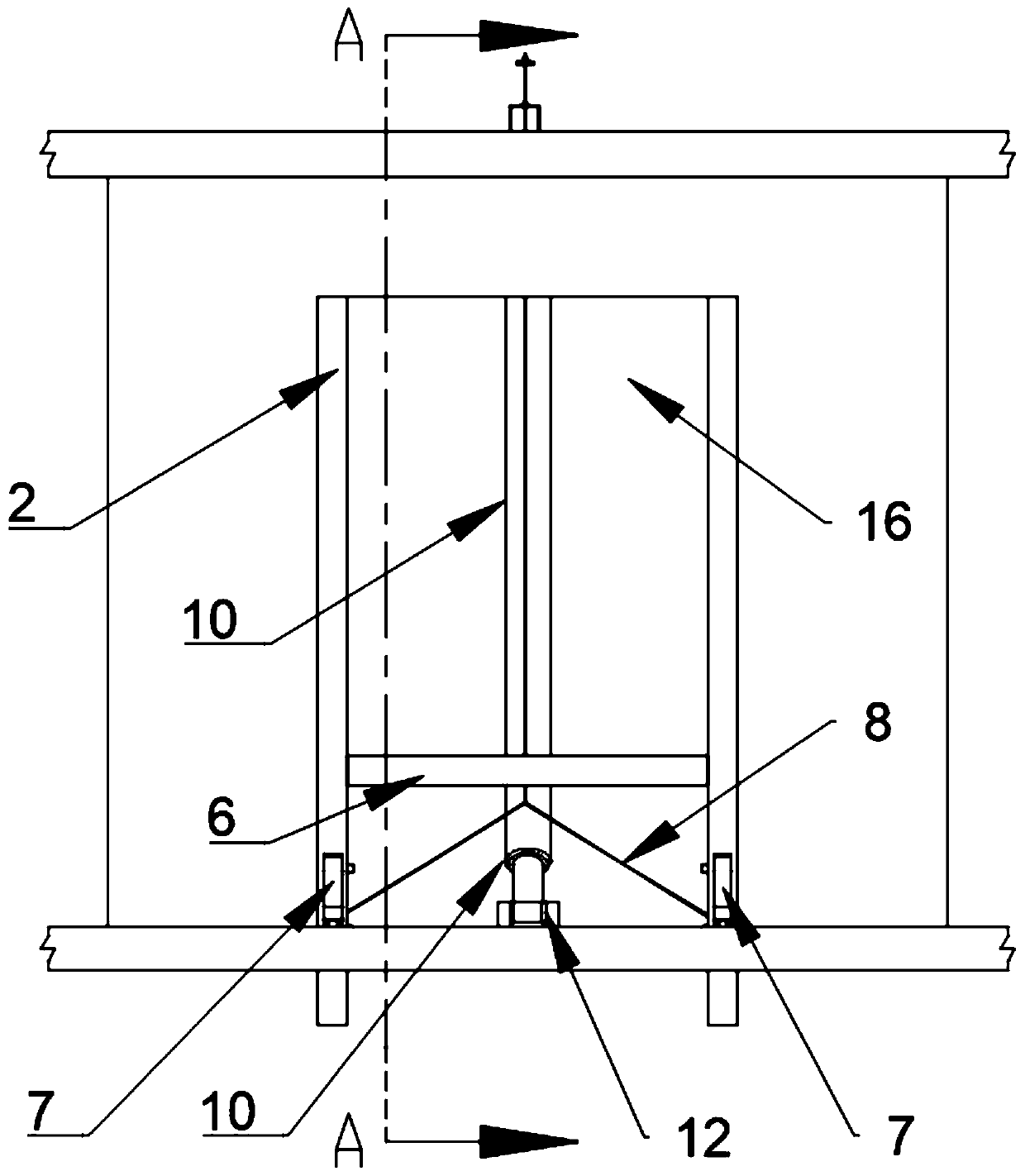

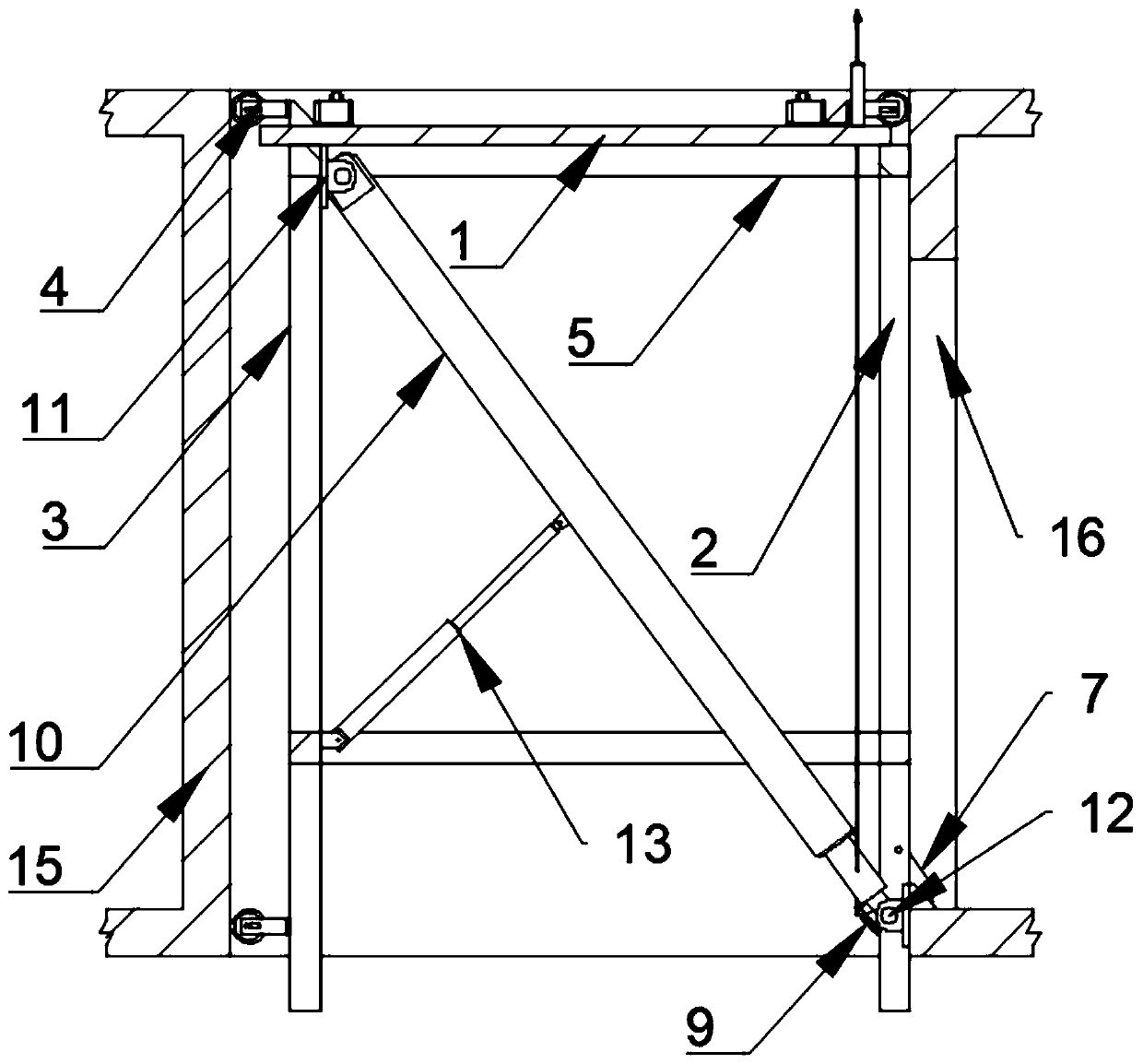

[0037] Such as Figure 1 to Figure 8 As shown, the present invention provides a kind of construction method that is applied to elevator shaft lifting platform in construction engineering, comprises the following steps:

[0038] Step 1. Build a workbench 1 in the elevator 15. The length and width of the workbench 1 are set according to the actual length and width of the elevator shaft 15. A gap needs to be reserved between the edge of the workbench 1 and the side wall of the elevator shaft 15 to prevent work. Platform 1 collides or gets stuck with the wall of elevator shaft 15 . The workbench 1 is lower than the top surface of the elevator shaft 15 , so that the side wall of the workbench 1 on the side away from the elevator shaft door opening 16 abuts against the wall of the elevator shaft 15 . The workbench 1 is composed of a rectangular frame welded by longitudinal beams and transverse beams and patterned steel plates, and the patterned steel plates are welded on the top of...

Embodiment 2

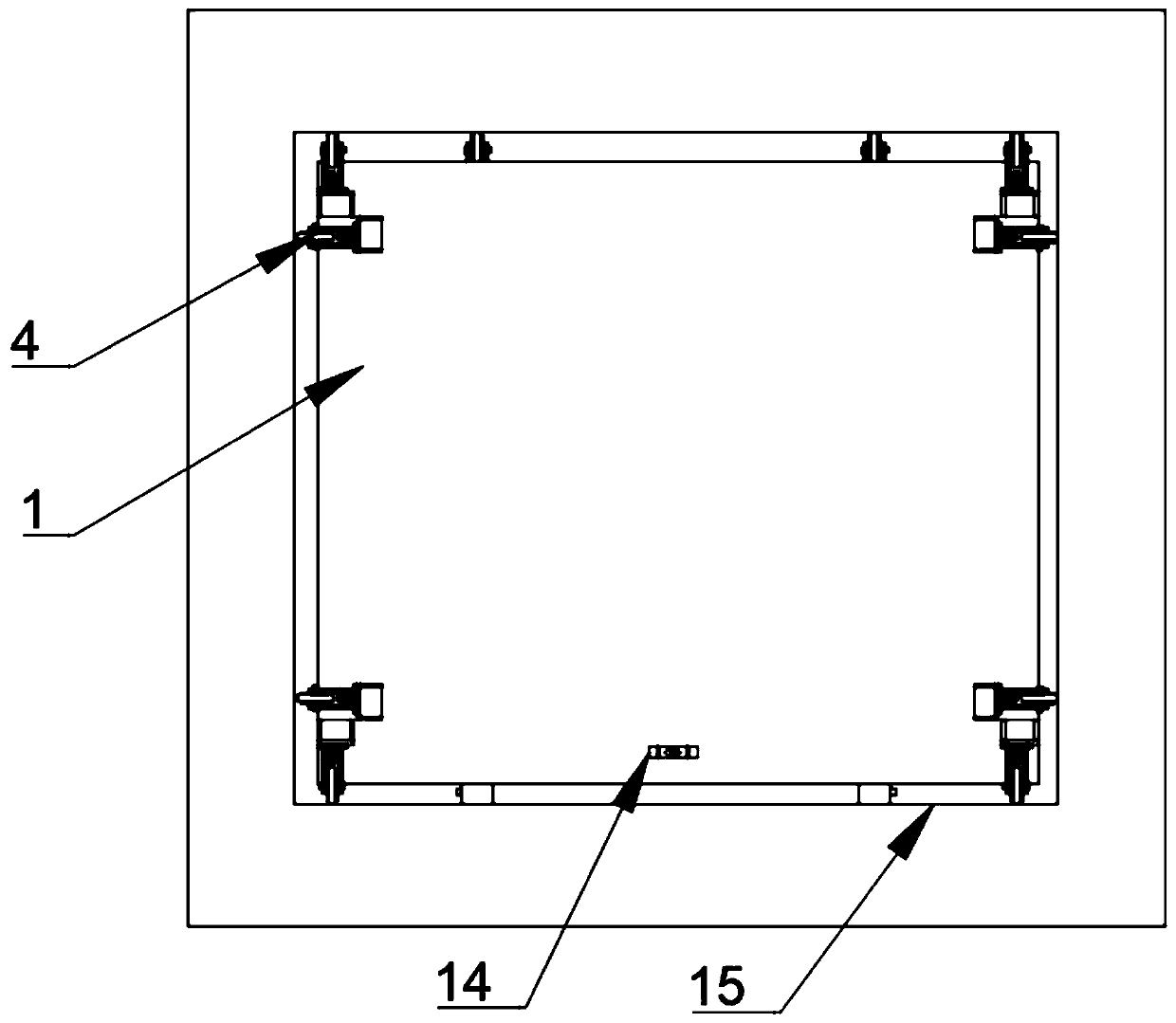

[0045] Such as figure 2 , image 3 with Figure 9 As shown, the present invention is a construction method applied to elevator shaft lifting platform in construction engineering. Compared with Embodiment 1, the difference between this embodiment and Embodiment 1 is that rubber rolling wheel assemblies 4 are fixedly connected around the workbench 1, and the rubber rolling wheels The wheel assembly 4 is in rolling connection with the walls of the elevator shaft 15 . The bottom of the second column 3 is fixedly connected with a rubber rolling wheel assembly 4, which is rollingly connected with the wall of the elevator shaft 15, and the rubber rolling wheel assembly 4 moves vertically up and down in the elevator shaft 15 following the workbench 1.

[0046] Specifically: the rubber roller assembly 4 includes a mounting plate 41, a support frame 42, a compression spring 46, a compression spring positioning shaft 45, a spring push plate 47, a rubber roller 43, a roller shaft pin 4...

Embodiment 3

[0049] Such as figure 1 , image 3 , Figure 5 to Figure 8 As shown, the present invention is a construction method applied to the elevator shaft lifting platform in construction engineering. The difference between this embodiment and Embodiment 1 is that the top of the shear key 7 passes through the cylindrical pin and the first column in the elongated hole. 2 Rotational connection, the shear key 7 is fixedly connected with a T-shaped tie rod 17 on the side away from the elevator shaft door hole 16. One end of the T-shaped tie rod 17 is threadedly connected with the shear key 7, and after the bottom of the shear force key 7 stretches out from the elongated hole, the other end of the T-shaped tie rod 17 is offset against the side wall of the first column 2. After the bottom of the shear key 7 retracts into the elongated hole, the other end of the T-shaped tie rod 17 is away from the side wall of the first column 2, and the T-shaped tie rod 17 is used to control the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com