BIM-based automatic borehole perpendicularity monitoring method

An automatic monitoring and verticality technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of construction process obstruction, lack of overall stability, water seepage in the hole, etc., to achieve novel and reasonable design, easy to promote Use, use with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

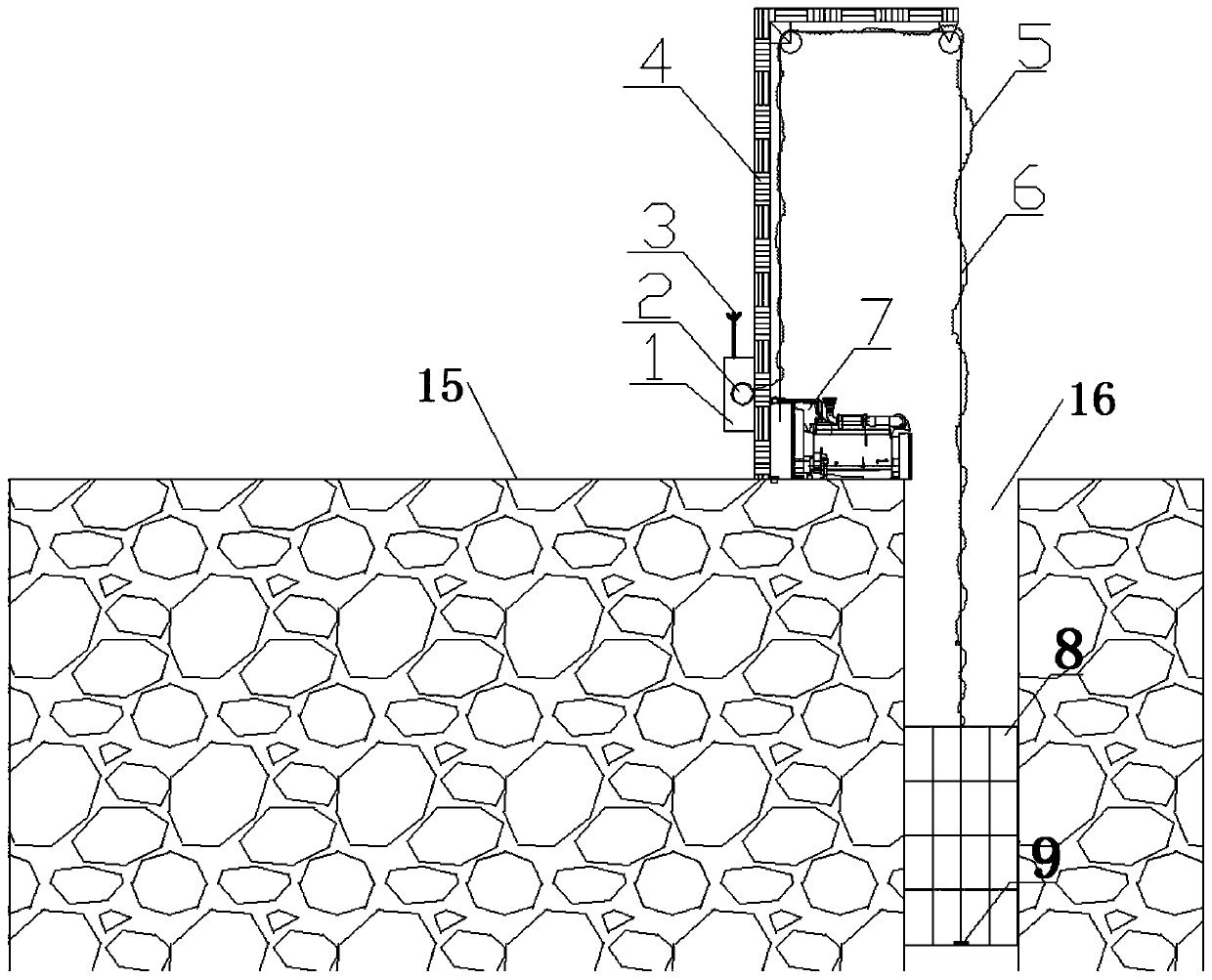

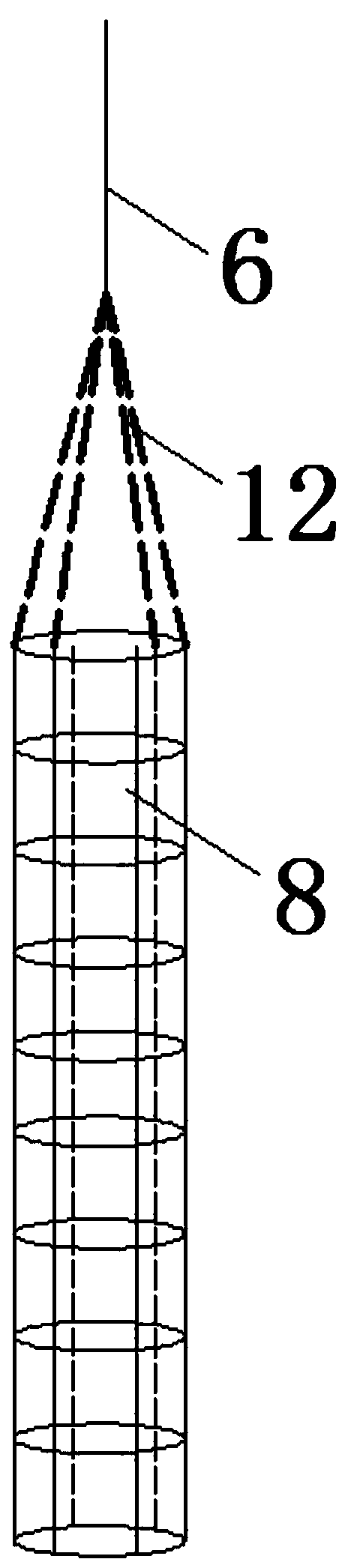

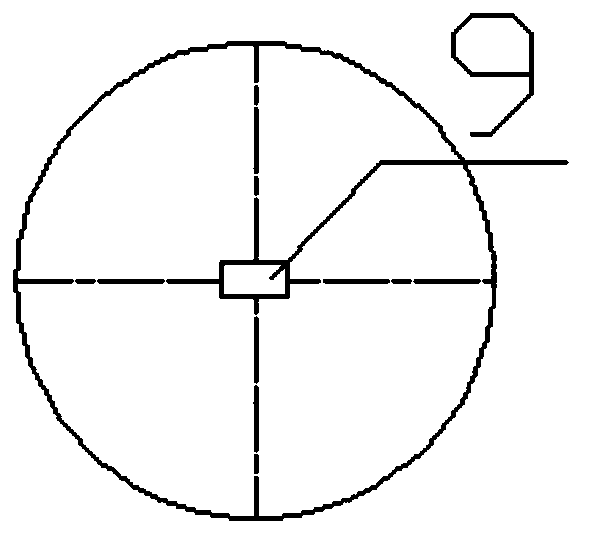

[0048] Such as Figure 1 to Figure 5 Shown, the present invention is based on the drilling verticality automatic monitoring method of BIM, comprises the following steps:

[0049] Step 1. Construct the drilling verticality detection mechanism, the process is as follows:

[0050] Step 101, install an inverted L-shaped support frame 4 on the side of the construction ground 15 at the top of the borehole 16, and the horizontal section of the inverted L-shaped support frame 4 is located in the center of the borehole 16 at the end of the vertical section of the inverted L-shaped support frame 4. On the axis, a pulley block is installed on the inner side of the inverted L-shaped support frame 4, and a crane 7 is installed on the construction ground 15, and the crane 7 is located on the inner side of the inverted L-shaped support frame 4;

[0051] It should be noted that the purpose of the horizontal section of the inverted L-shaped support frame 4 away from the end of the vertical se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com