System for exhaust gas recirculation tube alignment

An intake system, intake manifold technology, applied in exhaust gas recirculation, charging system, combustion air/combustion-air treatment, etc., can solve problems such as manufacturing delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

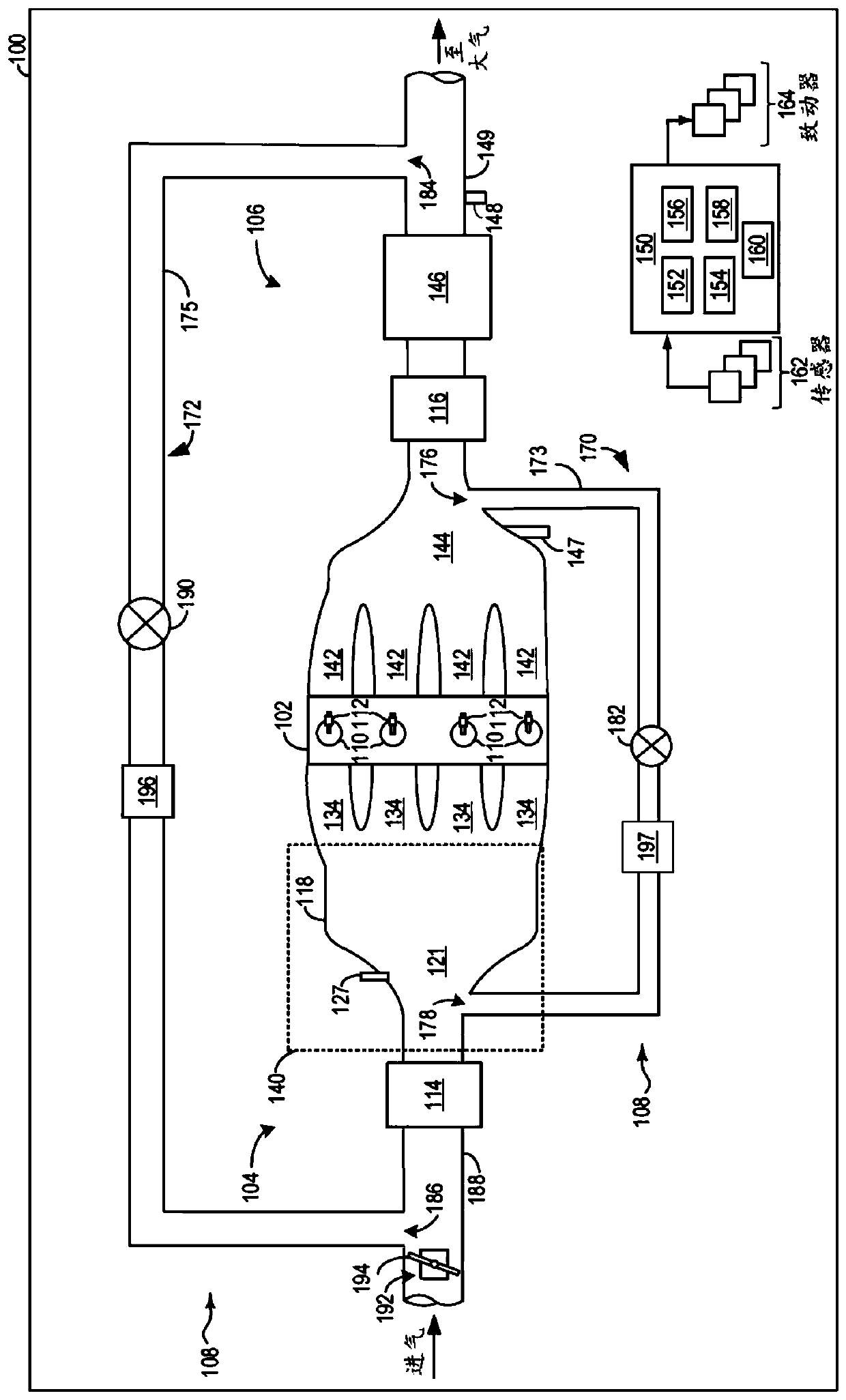

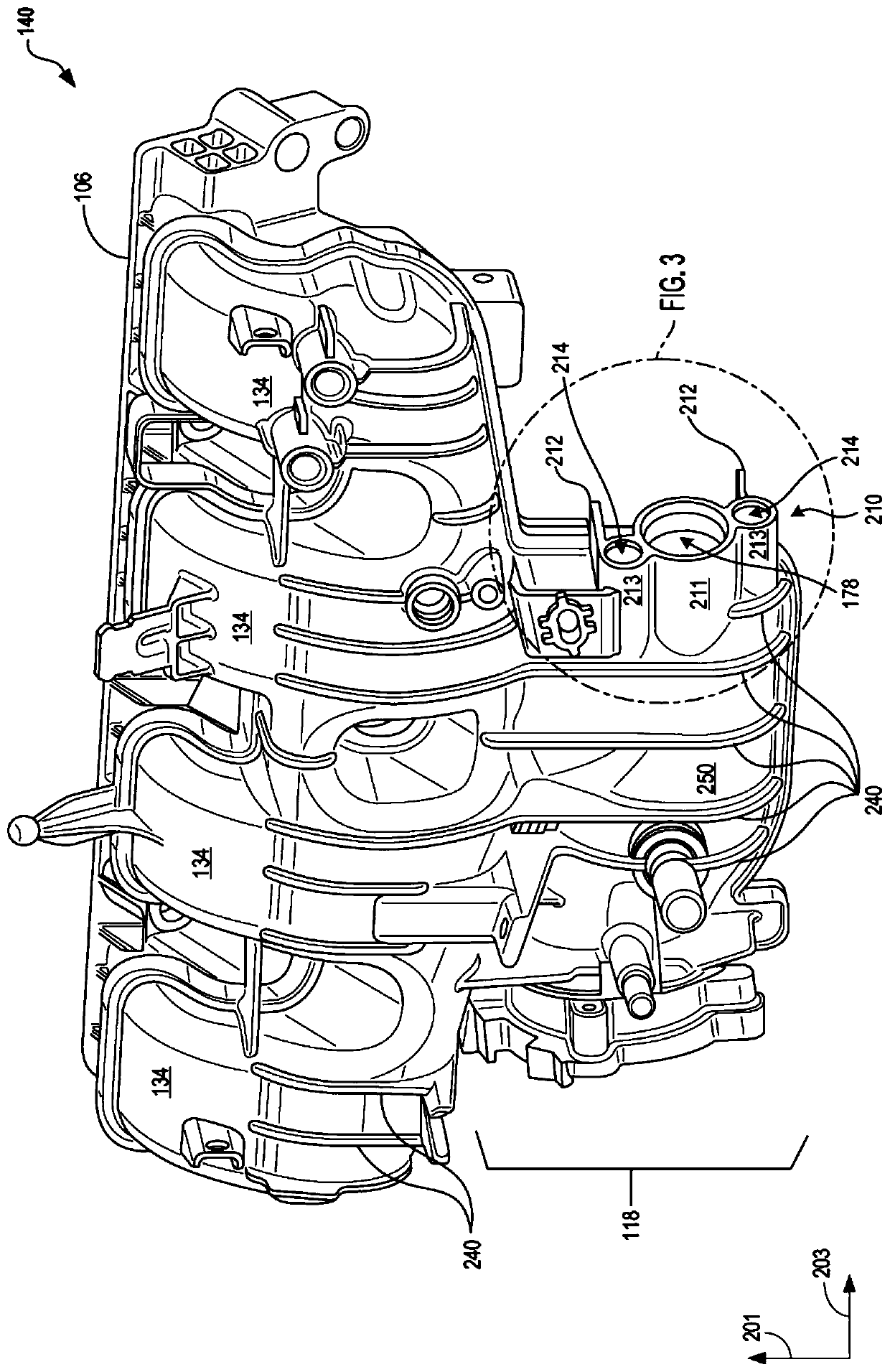

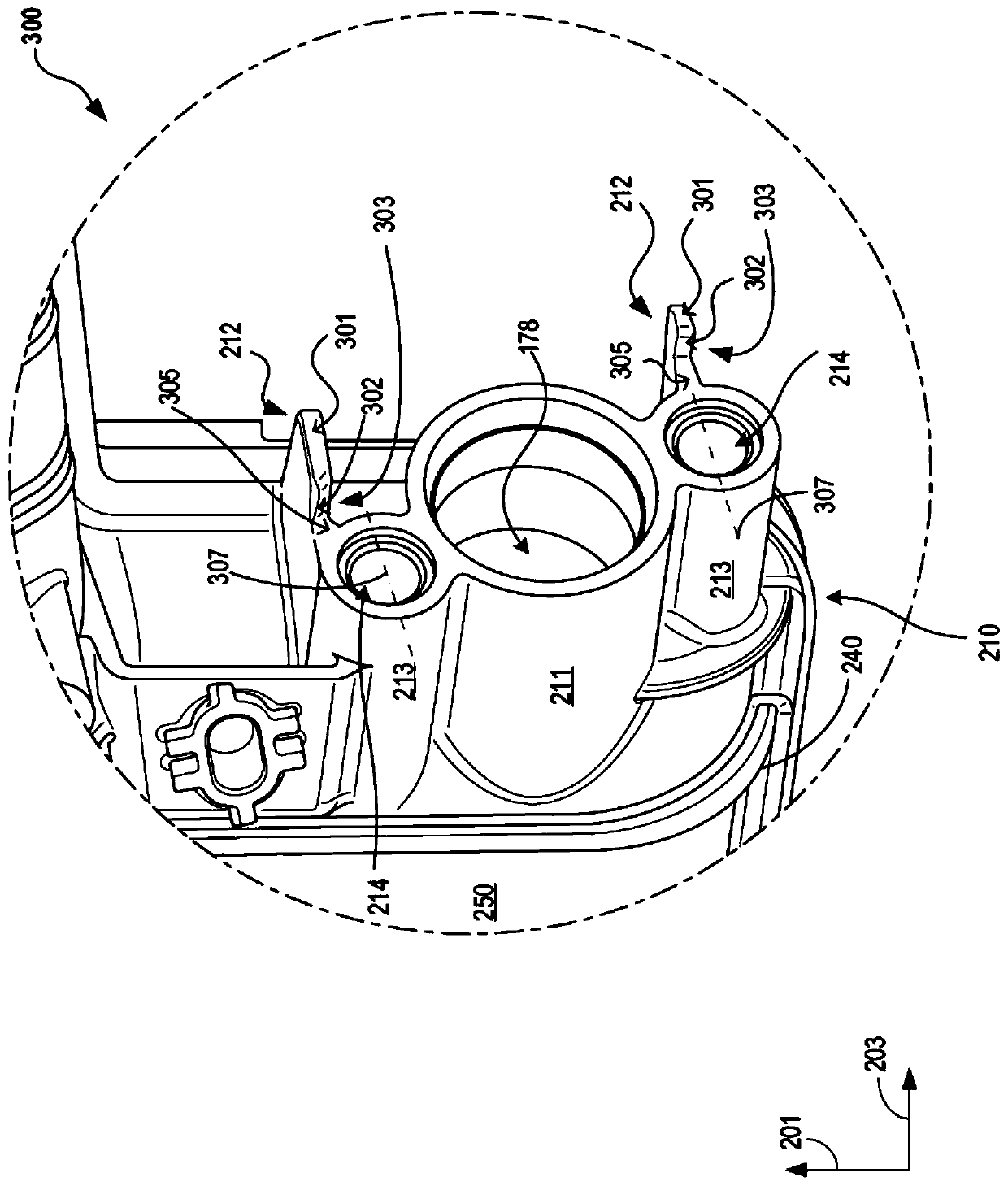

[0020] The following description pertains to integrating the exhaust gas recirculation (EGR) duct assembly with vehicle systems such as figure 1 The intake pipes of the vehicle system in the system) are installed together. Specifically, the following description relates to mounting features on the intake housing of a vehicle engine (which may be the intake manifold housing or the intake plenum housing) for assisting the integration of the EGR duct assembly with the intake air intake during the assembly process. Alignment and installation of gas housing. For example, during the manufacturing / development phase of a vehicle's lifecycle, particularly during the installation of the EGR pipe assembly to the intake housing, misalignment of the EGR pipe assembly to the intake housing may cause the EGR pipe assembly and intake manifold to Improper coupling between pipe shells. Therefore, a tight seal between the EGR pipe assembly and the intake housing may not be established. Theref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com