A hydraulic dual-mass flywheel

A dual-mass flywheel and flywheel technology, applied in the flywheel and other directions, can solve the problems that cannot be eliminated and affect the smooth effect of power transmission, and achieve the effect of improving transmission smoothness, isolating torsional vibration and rolling vibration, and improving smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

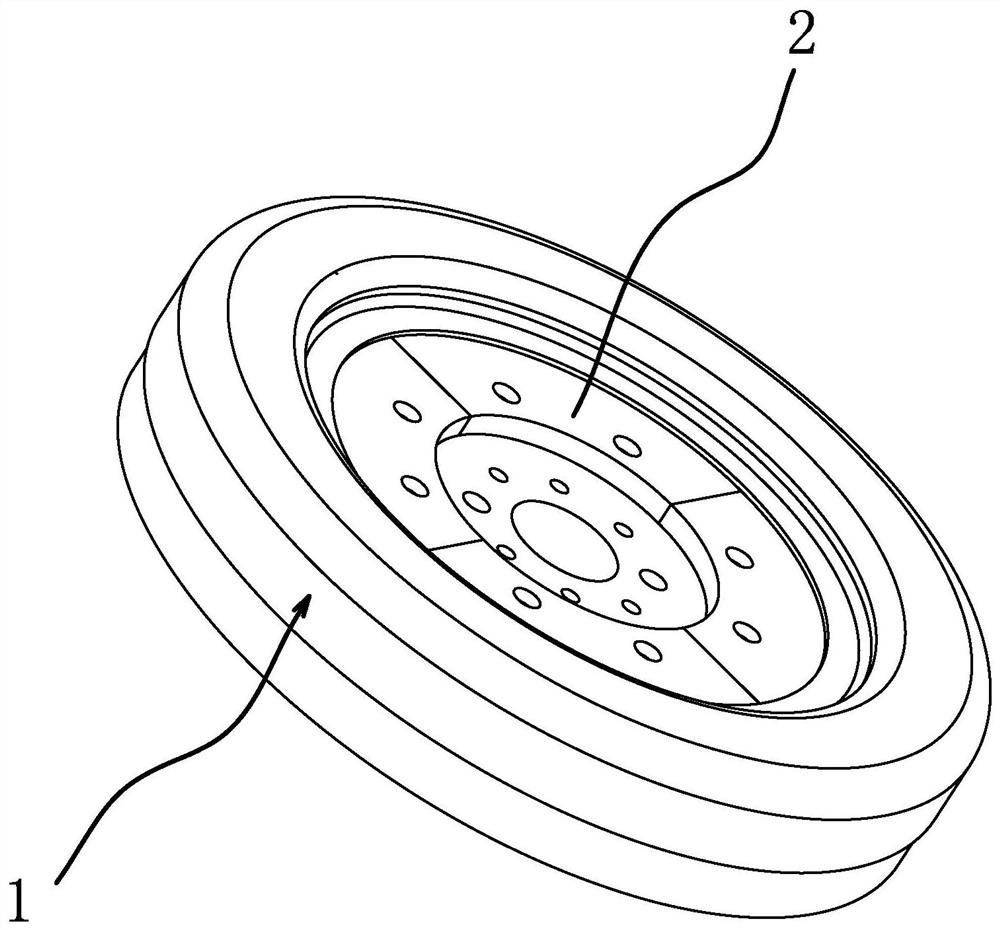

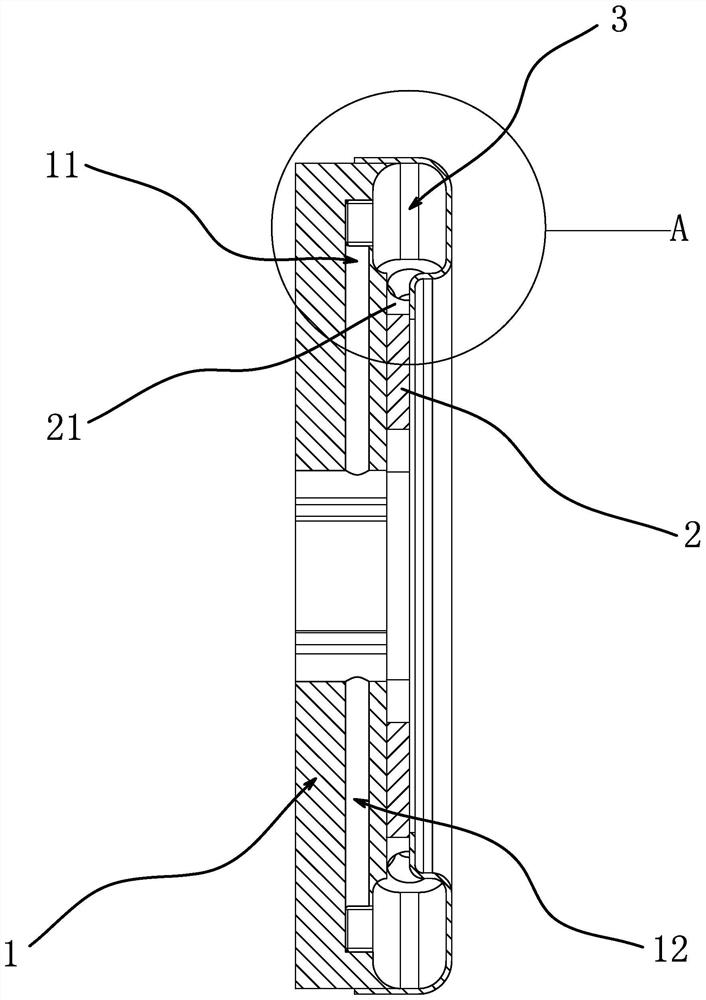

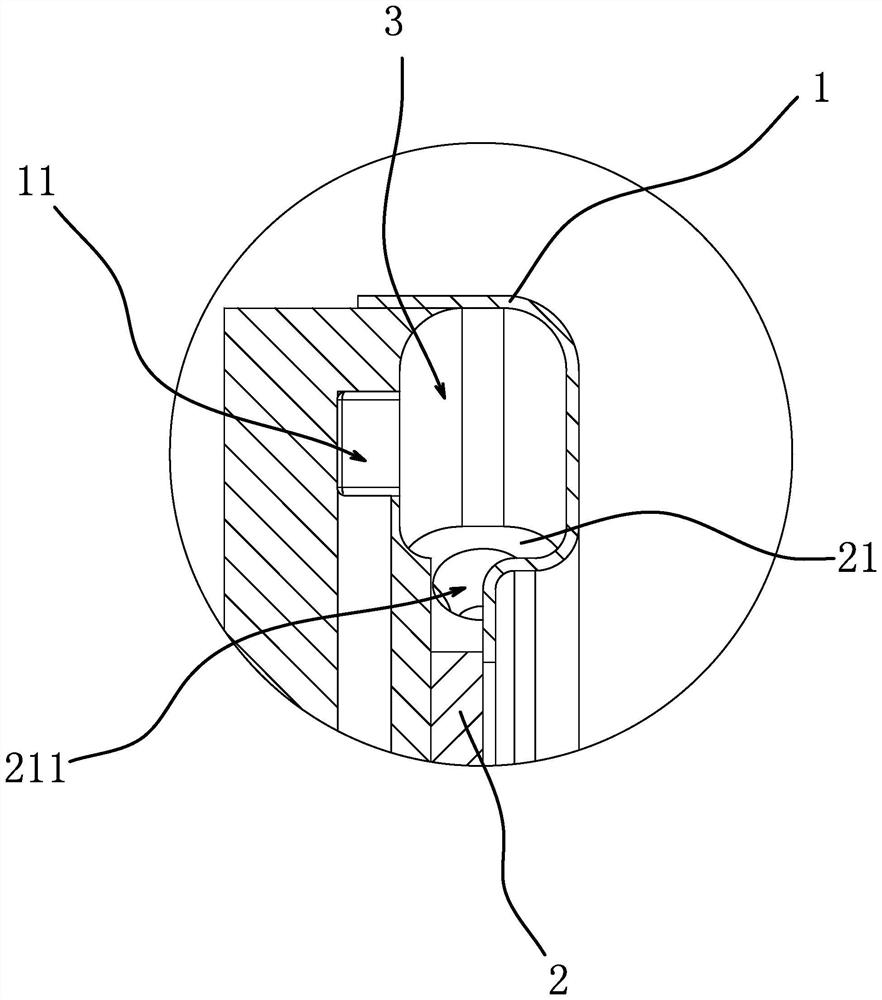

[0034] Such as figure 1 , figure 2 , Image 6 , Figure 7 As shown, the hydraulic dual-mass flywheel includes a main flywheel 1 and a secondary flywheel 2 that are coaxially arranged and can rotate relatively. The main flywheel 1 has an oil injection channel 11 whose inlet can communicate with the oil pump. The outlet of the oil injection channel 11 faces Auxiliary flywheel 2 has a diaphragm 21 extending radially on the auxiliary flywheel 2. When the main flywheel 1 rotates relative to the auxiliary flywheel 2, the oil gushed out from the outlet of the oil injection channel 11 can be sprayed on the side of the diaphragm 21. The main flywheel 1 is used to connect with the crankshaft and rotate synchronously. When the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com