Customized electrothermal film

An electric heating film, the fourth technology, applied in the field of electric floor heating, can solve the problems of different power density, potential safety hazards of electric heating film, inability to adapt, etc., and achieve the effect of avoiding secondary processing, significant economic benefits, and stable electrical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

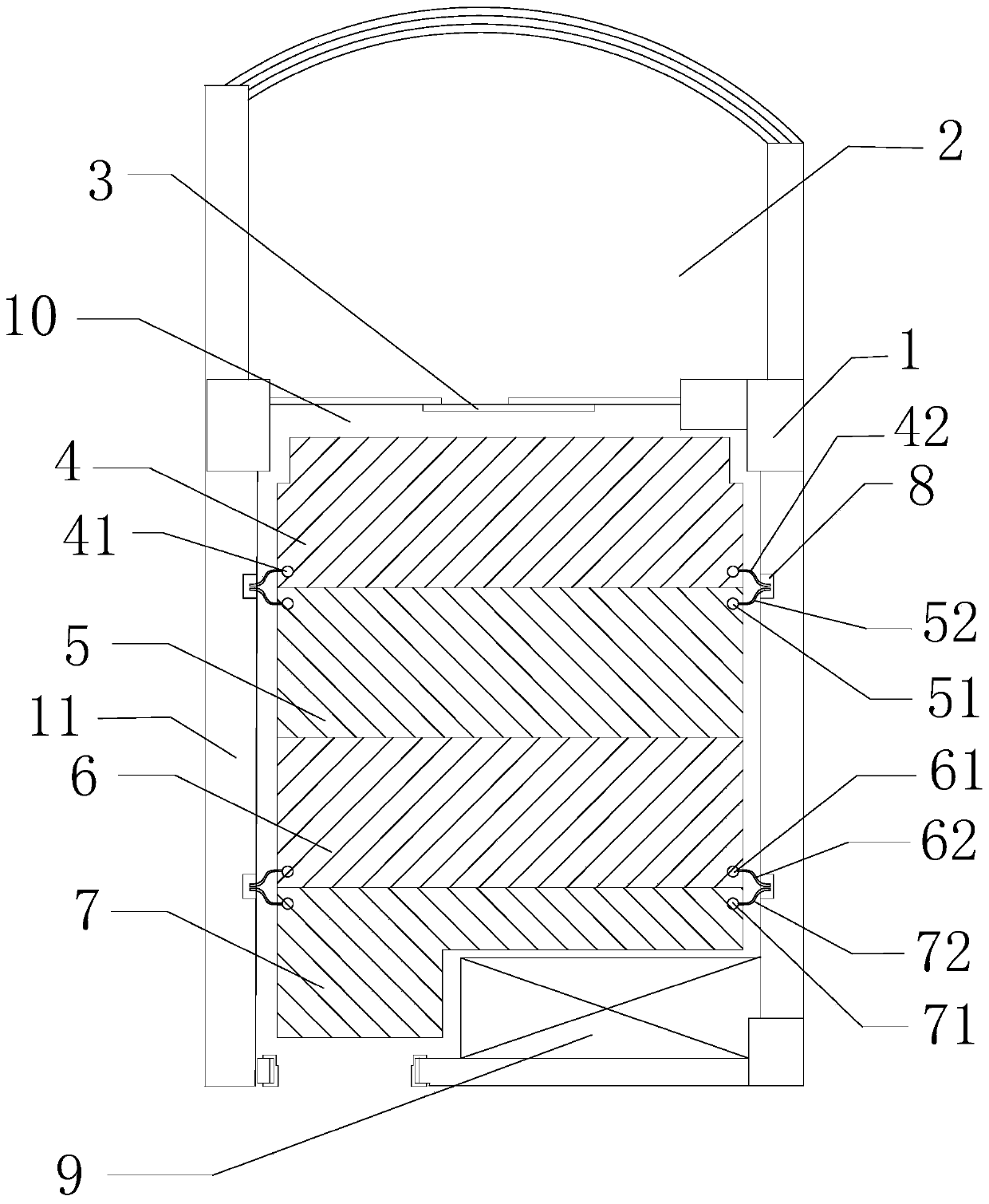

[0041] Such as figure 1 As shown, the present embodiment provides a customized electric heating film installed on the ground 10 of the room 1, the room 1 is equipped with a floor-to-ceiling glass window 3, and there is a balcony 2 outside the floor-to-ceiling glass window 3; including the first electric heating film 4, the second Two electrothermal films 5, third electrothermal films 6, fourth electrothermal films 7, four junction boxes 8, two first leads 42, two second leads 52, two third leads 62 and two fourth leads 72 ; The first electrothermal film 4, the second electrothermal film 5, the third electrothermal film 6 and the fourth electrothermal film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com