Special fiber glass melting method and its special electric melting furnace

A special fiber and melting technology, applied in glass furnace equipment, glass manufacturing equipment, glass production, etc., can solve the problems of shortening kiln life, not conducive to ensuring the quality of molten glass, and large temperature changes in hot spots, so as to reduce the melting area , good wire drawing process performance, and the effect of improving the area melting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] A special fiber glass melting method, the steps comprising:

[0044] 1) Prepare the mixture: the raw materials of each component are calculated in parts by weight: quartz sand: 52, alumina: 26, boron oxide: 3, cerium oxide: 2, iron oxide: 2, magnesium oxide and calcium oxide The sum of those: 15, pulverized, uniformly mixed by air force, the particle size of the powder is about 190 microns.

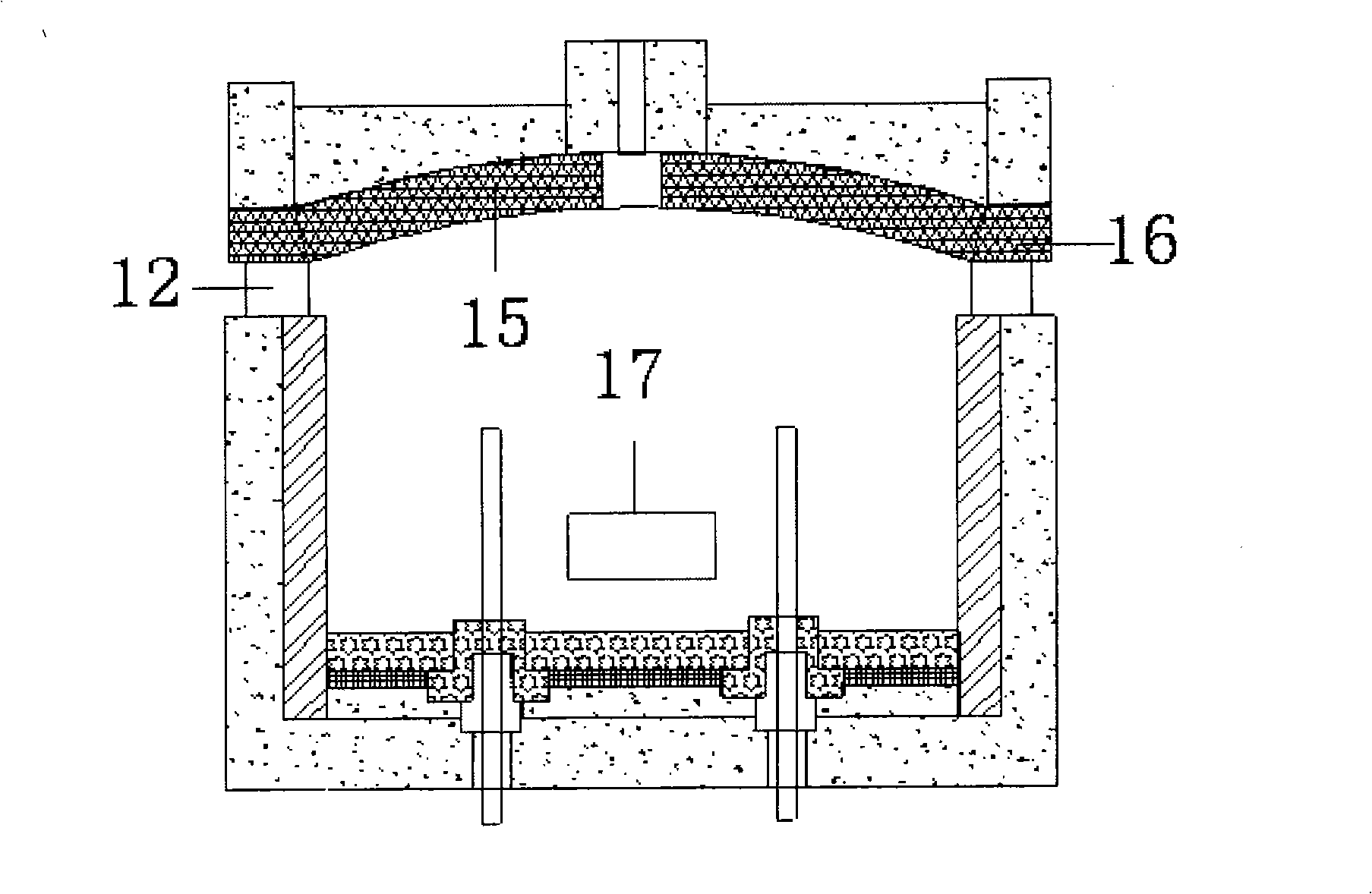

[0045] 2) Melting: put the powder obtained in step 1) into an electric melting furnace for melting, and the melting temperature is controlled at about 1550°C;

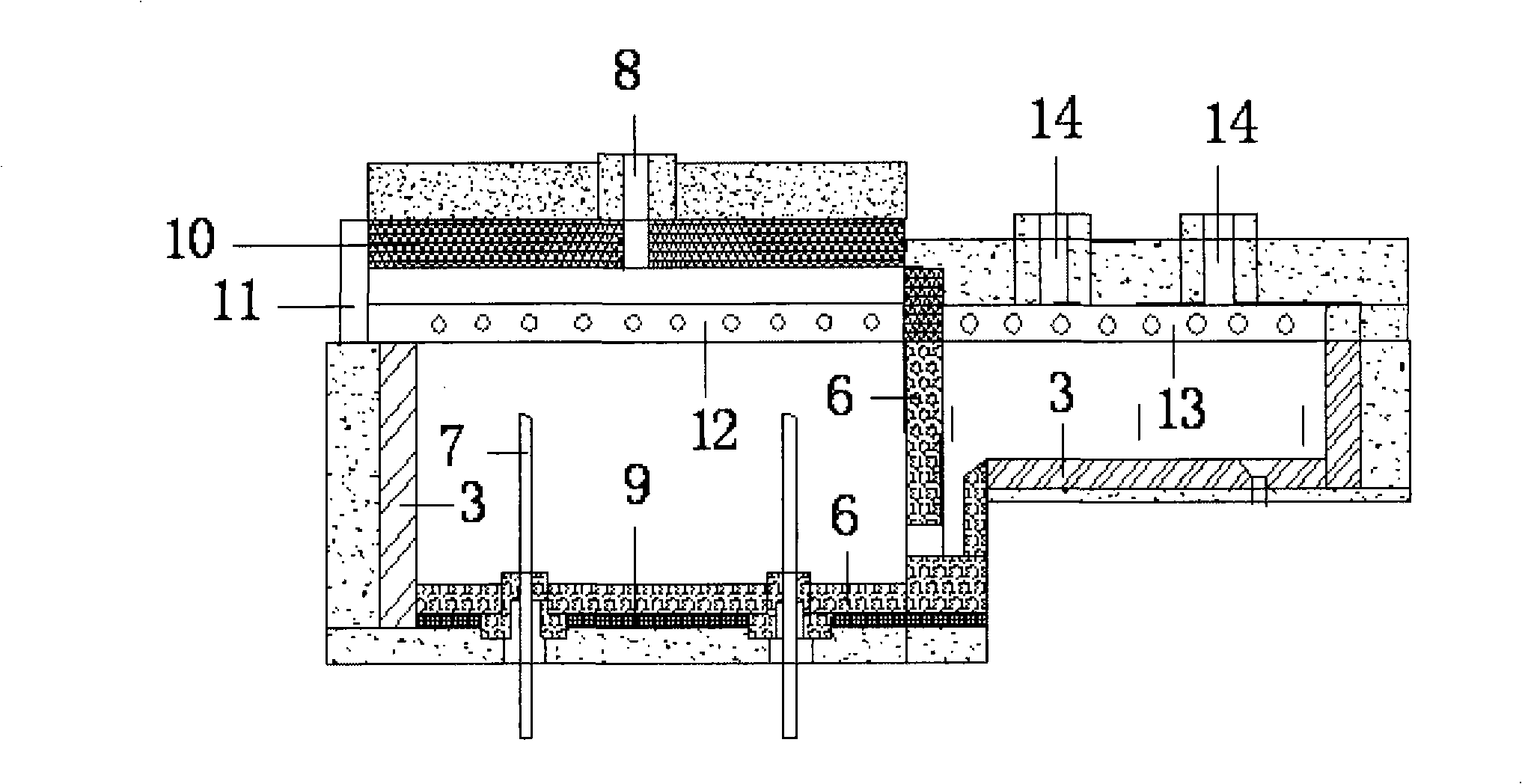

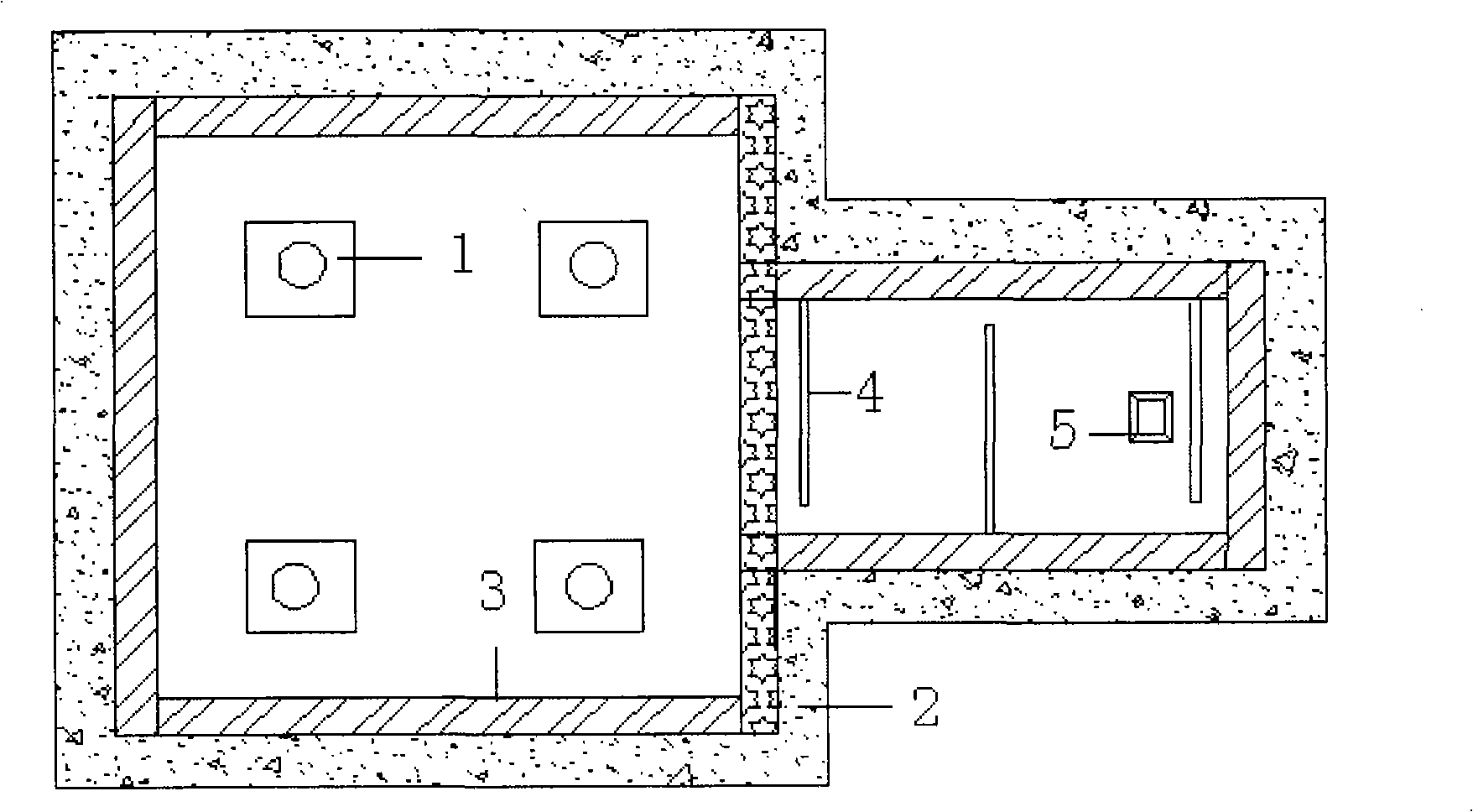

[0046] 3) Clarification: The high-temperature molten glass made in step 2) flows into a clarification tank lined with quartz bricks or masonry, and after clarification and homogenization, it flows into the operation pool; both the clarification tank and the operation pool are equipped with molybdenum electrodes The heating device flows out through the double-hole platinum drain plate, and the temperature of the outflow fro...

example 2

[0054] A special fiber glass melting method, the steps comprising:

[0055] 1) Prepare the mixture: the raw materials of each component are calculated in parts by weight: quartz sand: 57, alumina: 26, boron oxide: 3, cerium oxide: 2, iron oxide: 1, magnesium oxide and calcium oxide The sum of those: 11, weighed separately for use, the sum of the proportioning ratio of each component is 100, pulverized, uniformly mixed by air force, the particle size of the powder is about 210 microns.

[0056] 2) Melting: Put the powder obtained in step 1) into an electric melting furnace for melting, and the melting temperature is controlled at about 1580°C;

[0057] 3) Clarification: The high-temperature molten glass made in step 2) flows into a clarification tank lined with quartz bricks or masonry, and after clarification and homogenization, it flows into the operation pool; both the clarification tank and the operation pool are equipped with molybdenum electrodes The heating device flows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com