Gas pulse pressure generator and pressure generation method based on impact switching

A technology of pulse pressure and gas pulse, which is used in the measurement of fluid pressure, instruments, calibration/testing of force/torque/work instruments, etc., which can solve the problem that the pulse pressure cannot be covered, the pressure pulse width is difficult to control, and the repeatability of the pressure amplitude is poor. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

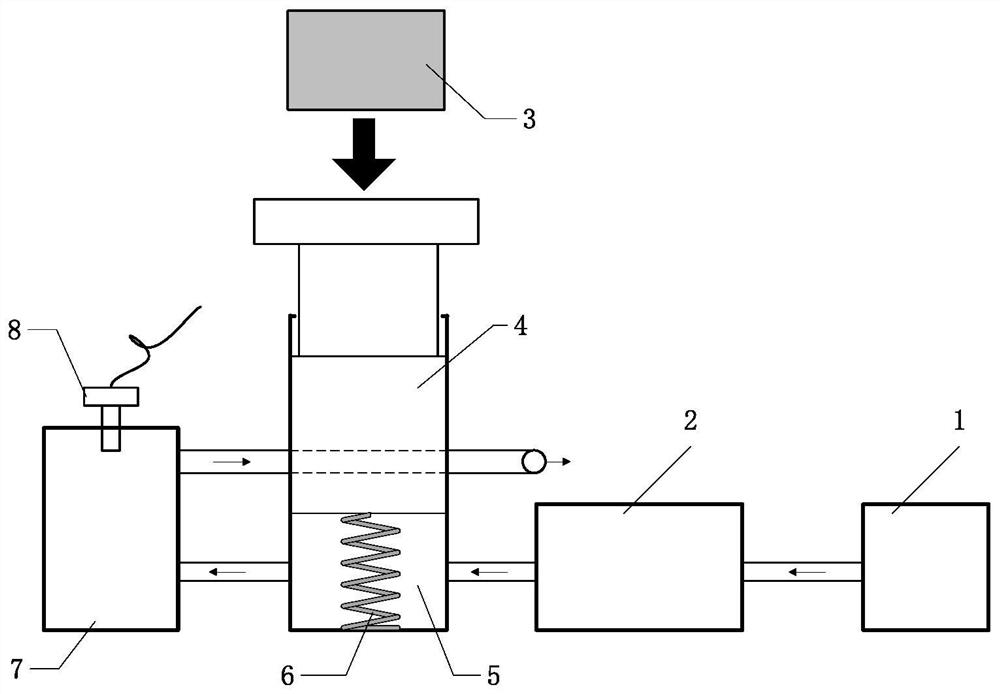

[0032] Such as figure 1 The gas pulse pressure generator based on impact switching disclosed in this embodiment is shown in the figure, consisting of a gas source 1, a gas pressure regulator mechanism 2, an impact excitation source 3, a piston rod 4, a piston cylinder 5, a spring 6, a pressure chamber 7 and 8 pressure sensors. One side of the piston cylinder 5 has an air inlet connected to the gas pressure regulating mechanism 2, and the other side has an air inlet at the middle part and an exhaust port at the bottom, and the air inlet in the middle part of the piston cylinder 5 is used to communicate with the gas pressure regulating mechanism 2. The exhaust port of the pressure chamber 7 is connected, and the exhaust port at the lower part of the piston cylinder 5 is used to communicate with the air inlet of the pressure chamber 7 . The piston rod 4 has a through hole. The gas source 1 communicates with the gas pressure stabilizing and regulating mechanism 2 . The gas pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com