A single-bow high-speed stranding machine

A stranding machine, high-speed technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of friction between wires and routing rings or rollers, affecting the effect of wire stranding, affecting the quality of wires, etc., to achieve structural design Ingenious, stable structure, and stable wire routing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

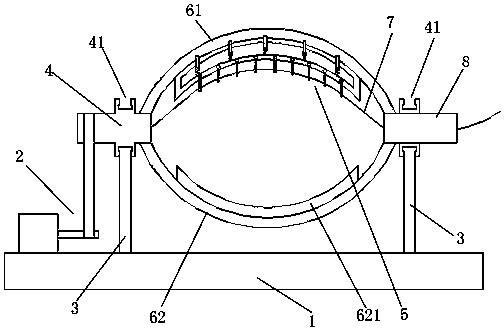

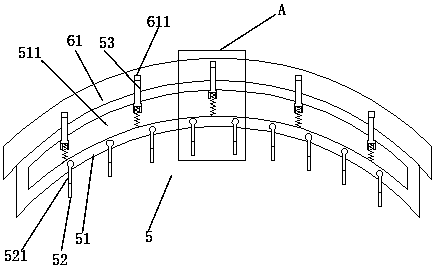

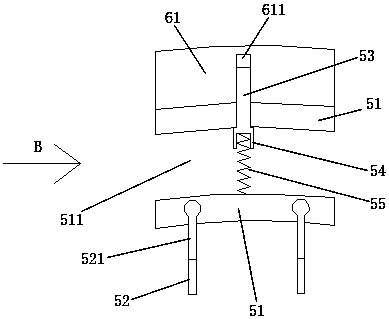

[0022] Such as Figures 1 to 5 As shown, a single-bow high-speed stranding machine includes a base 1 , a driving mechanism 2 , an incoming wire shaft 4 , an outgoing wire shaft 8 , an arc-shaped twisting bow, a support rod 3 , and a threading assembly 5 . The drive mechanism 2 is installed on one side of the upper end of the base 1 . Two parallel supporting rods 3 are installed on the base 1; the incoming wire shaft 4 and the outgoing wire shaft 8 are respectively rotated and installed on the upper ends of the supporting rods 3; the arc-shaped twisting bow includes an upper arc-shaped twisting bow 61 and the lower arc twisting bow 62; the upper and lower arc twisting bows 61 and the lower arc twisting bows 62 are fixed symmetrically up and down between the inlet shaft 4 and the outlet shaft 8; the drive mechanism 2 drives the inlet shaft 4 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com