Integrated double-stage double-linkage hydraulic intelligent crusher with mechanical arm structure

A two-stage, double-link, robotic arm technology, applied in the field of construction machinery, can solve problems such as affecting production efficiency, safety accidents, and potential safety hazards, and achieve the effects of reducing labor intensity and production cost, improving production efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

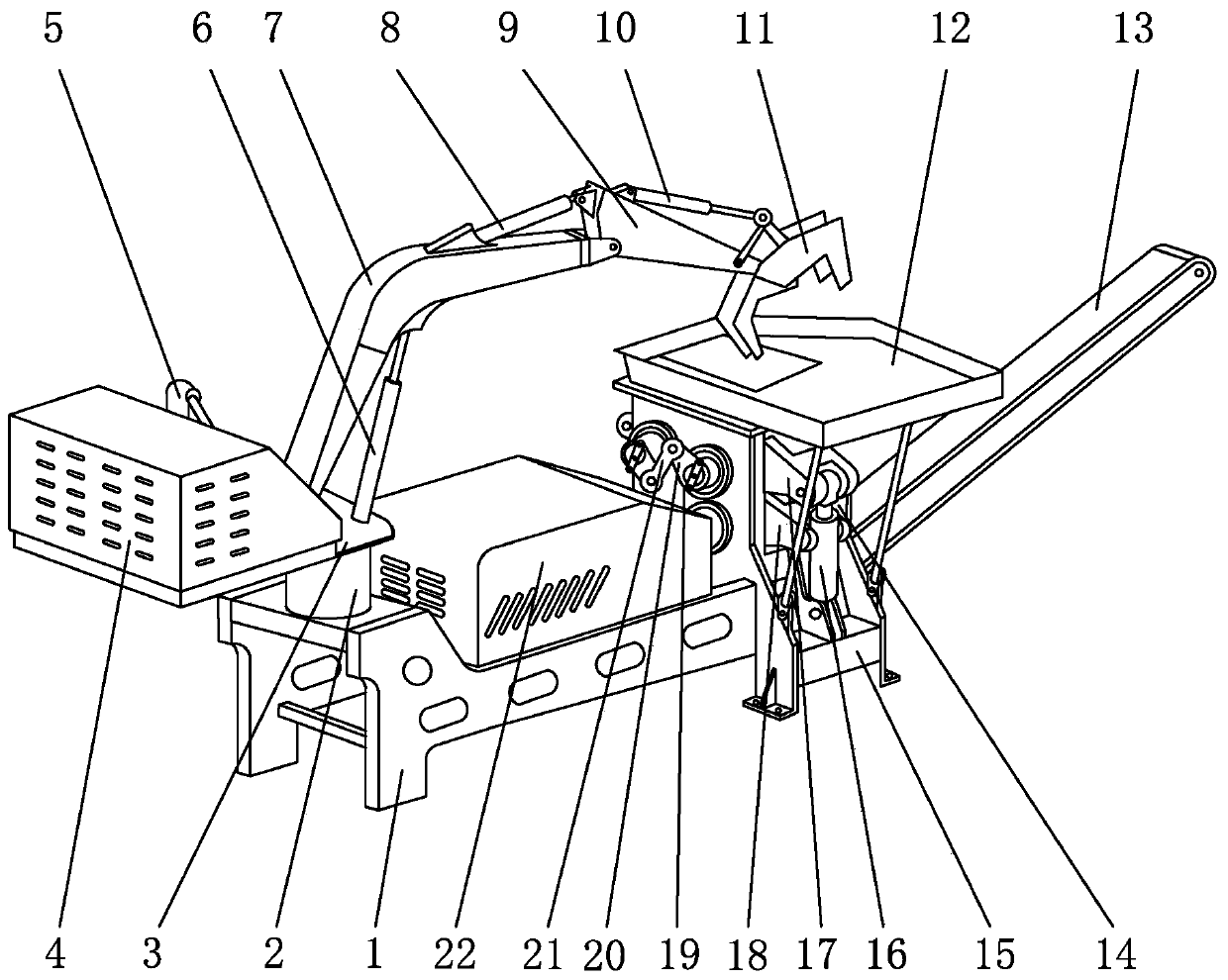

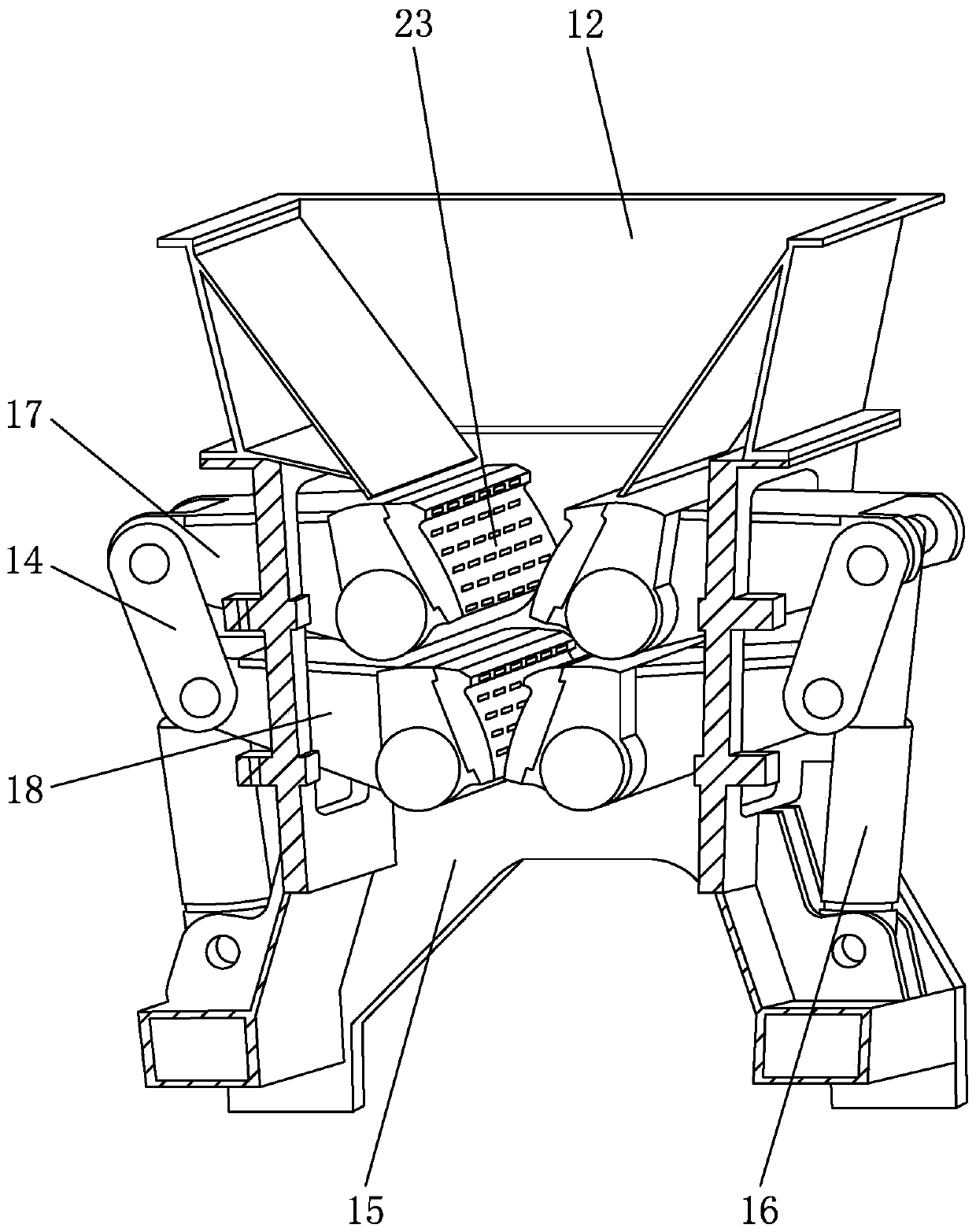

[0022] Such as figure 1 , 2 As shown, an integrated double-stage double-linkage hydraulic intelligent crusher with a mechanical arm structure includes a support frame 1 and a crushing support 15, the crushing support 15 is welded on one side of the support frame 1, and a hydraulic press 22 is provided on the top of the support frame 1. The top of the support frame 1 is provided with a rotary mechanism 2 at the end far away from the crushing bracket 15, the rotary mechanism 2 is provided with a rotary platform 3, the rotary platform 3 is provided with a mechanical arm, and the crushing bracket 15 is provided with two primary crushing pressure plates 17, The adjacent sides of the two primary crushing platens 17 are V-shaped, and the adjacent sides of the two primary crushing platens 17 are provided with platen heads 23, and the two primary crushing platens 17 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com