Hydraulic machine mold stamping rod

A technology of hydraulic presses and punching rods, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as stress concentration and punching rod breakage, and achieve the effects of uniform force, low pressure, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

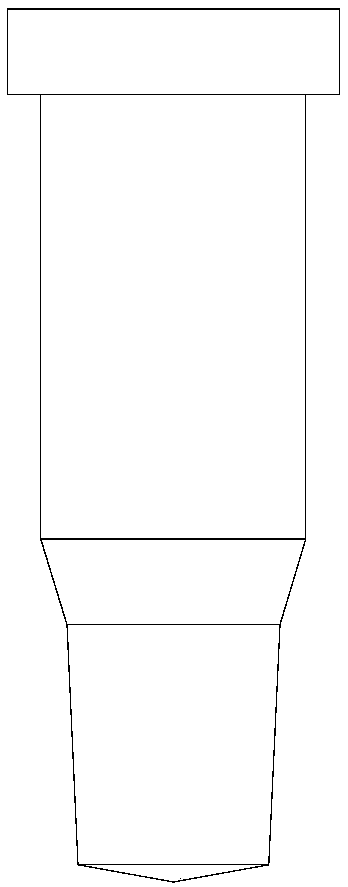

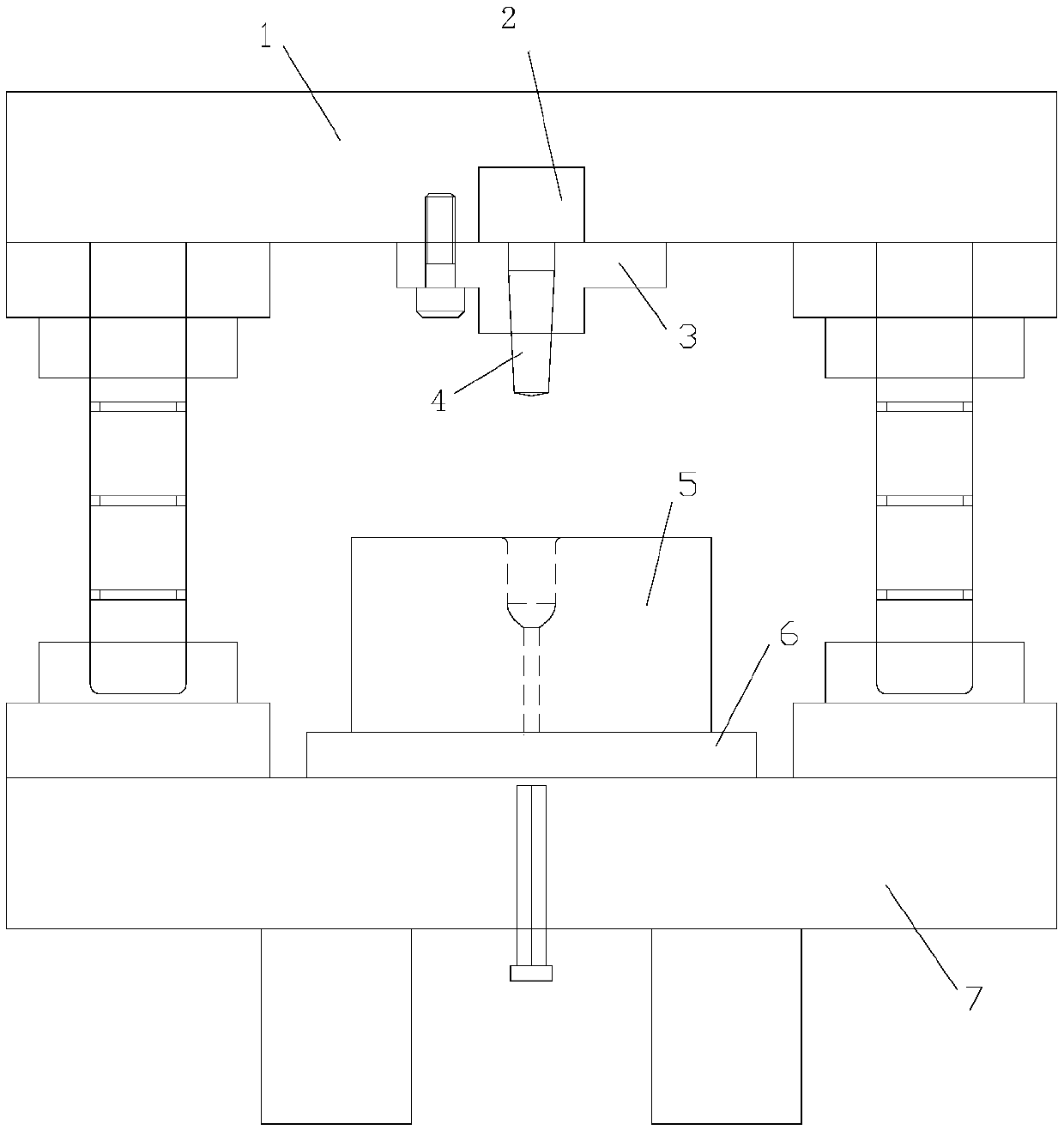

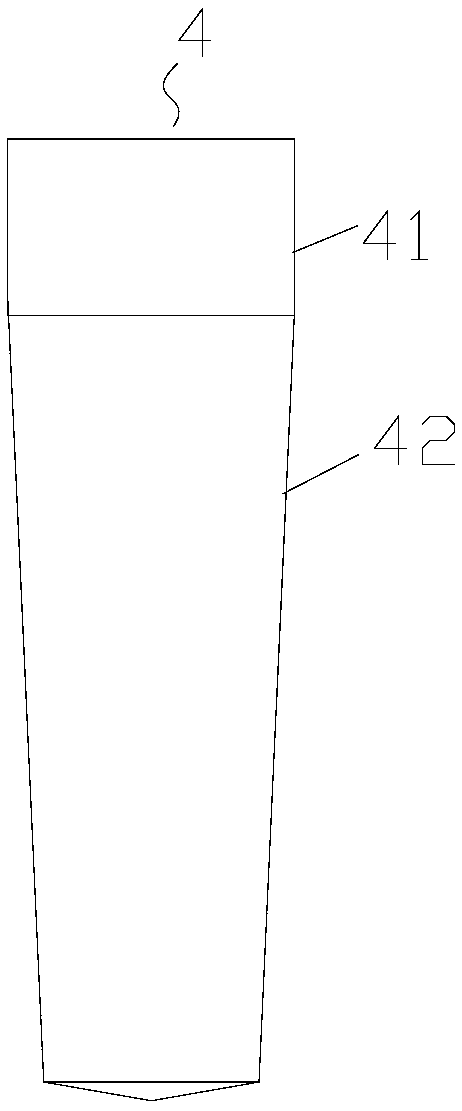

[0017] Such as figure 2 , 3 As shown, a hydraulic press mold for an electrode cap includes an upper mold base 1, an upper backing plate 2, an upper clamping plate 3, a punch 4, a lower template 5, a lower mold pad 6 and a lower mold base 7, and the punch 4 is a rotary The body is divided into two sections along its length, including a cylindrical section 41 and a circular frustum section 42. The two sections are integrally formed, and the junction is smoothly transitioned. The diameter of the end of the circular platform section away from the cylindrical section is small. The ratio is 1:4; the taper of the frustum segment 42 is 1:10. The installation cavity for clamping the punch in the upper clamping plate includes an upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com