Welding device of radiating tube of radiator

A technology for welding devices and cooling pipes, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor stability of manual turning and dislocation of welding ports, etc., and achieve the effects of saving manpower, increasing positioning, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

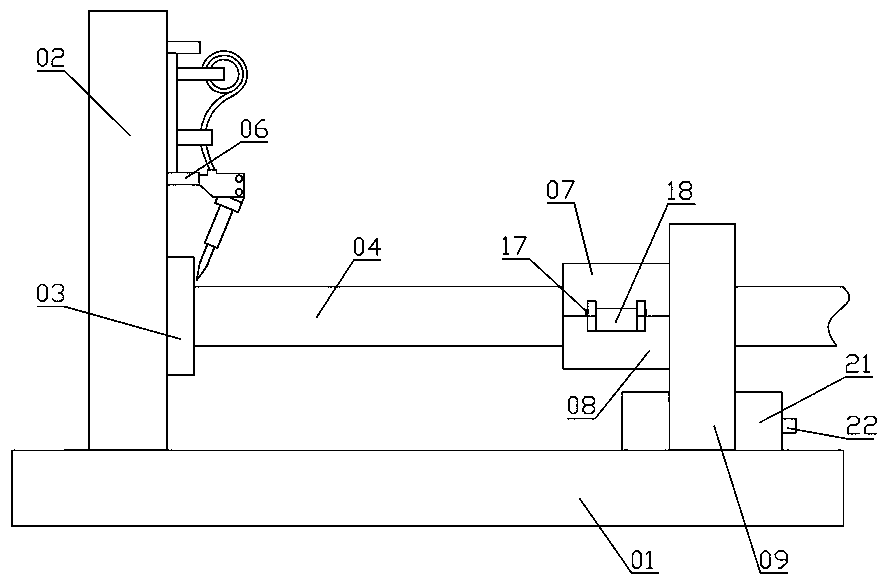

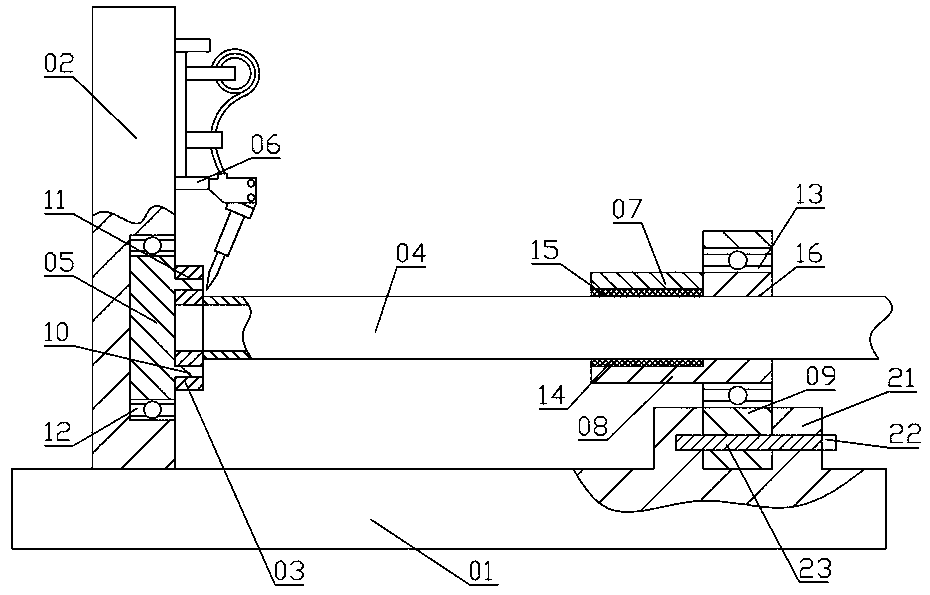

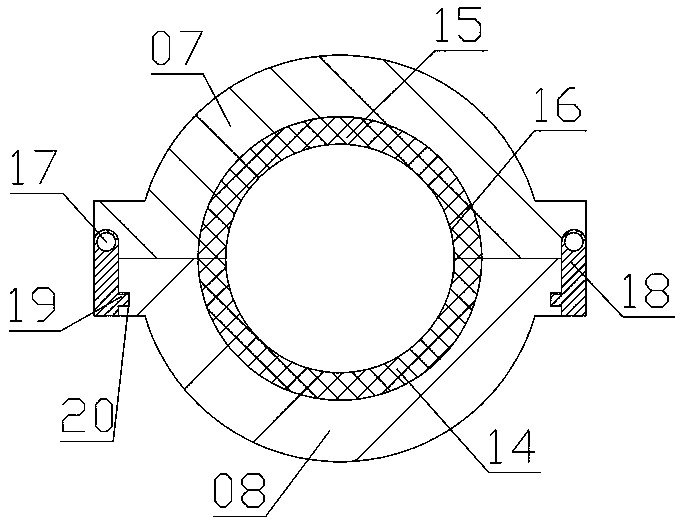

[0014] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0015] A heat dissipation pipe welding device for a radiator, comprising a bottom plate 01, a back plate 02, a positioning plate 05, a welding torch frame 06, a reinforcement plate 07, a support plate 08, a No. 1 bearing 12, a No. 2 bearing 13, and a buckle plate 18. The bottom of the plate 02 is connected to the bottom plate 01, the inside of the back plate 02 is connected to the welding torch holder 06, the back plate 02 is connected to the outside of the No. 1 bearing 12, the inside of the No. 1 bearing 12 is connected to the positioning plate 05, and the positioning plate 05 is connected to the flange 03. Mounting holes 11, the positioning plate 05 has a plurality of positioning rods 10, the positioning rods 10 are adapted to the mounting holes 11, the positioning rods 10 are connected to the mounting holes 11, the flange 03 is connected to the heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com