Self-equalization multi-bundle pre-stressed anchor cable connection structure and construction method thereof

A prestressed anchor cable and self-balancing technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of narrow construction space of foundation pit fertilizer trough, affecting the backfilling and compaction of foundation pit fertilizer trough in the construction of basement exterior wall, etc. The effect of improving safety, saving steel and improving balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

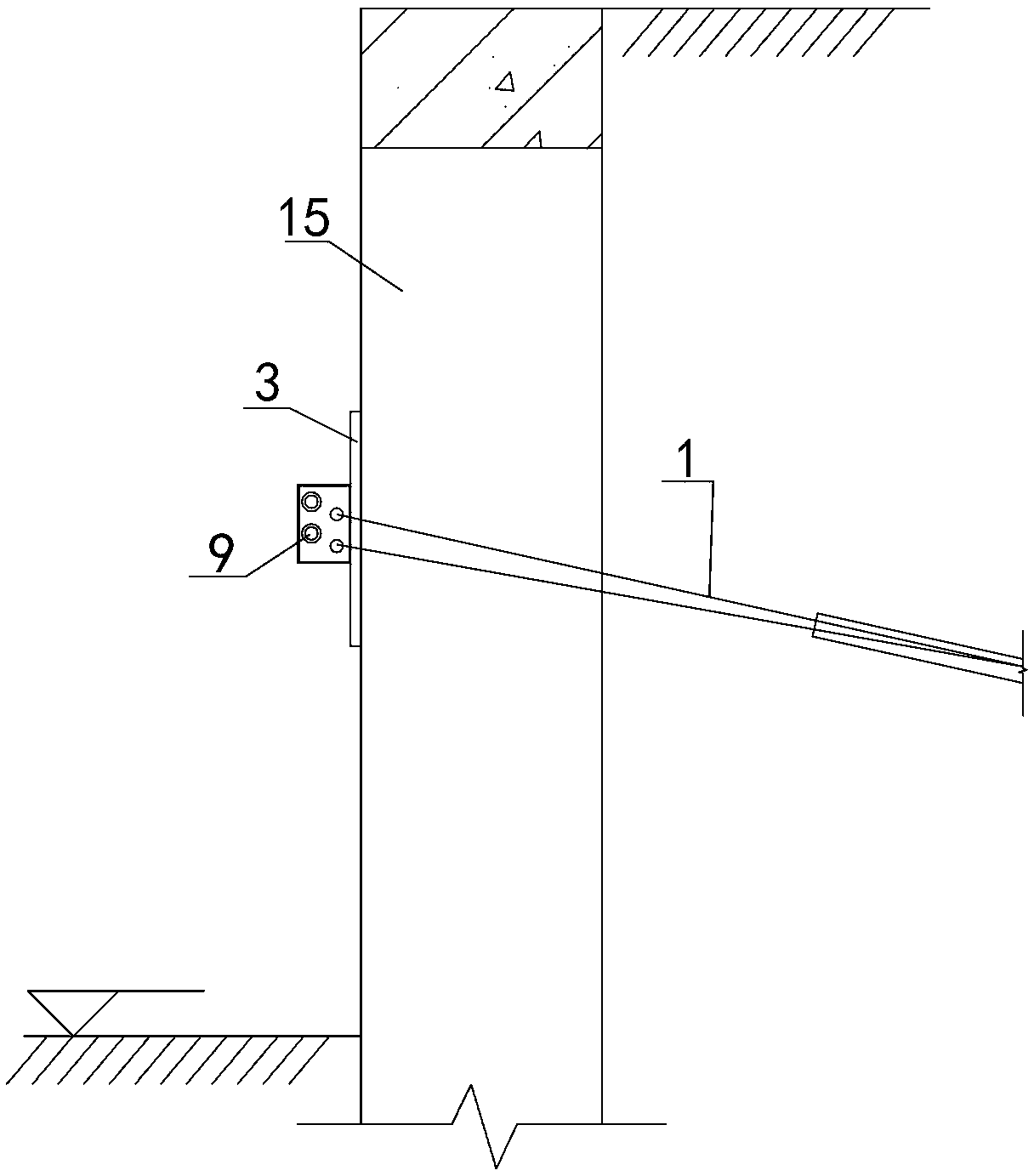

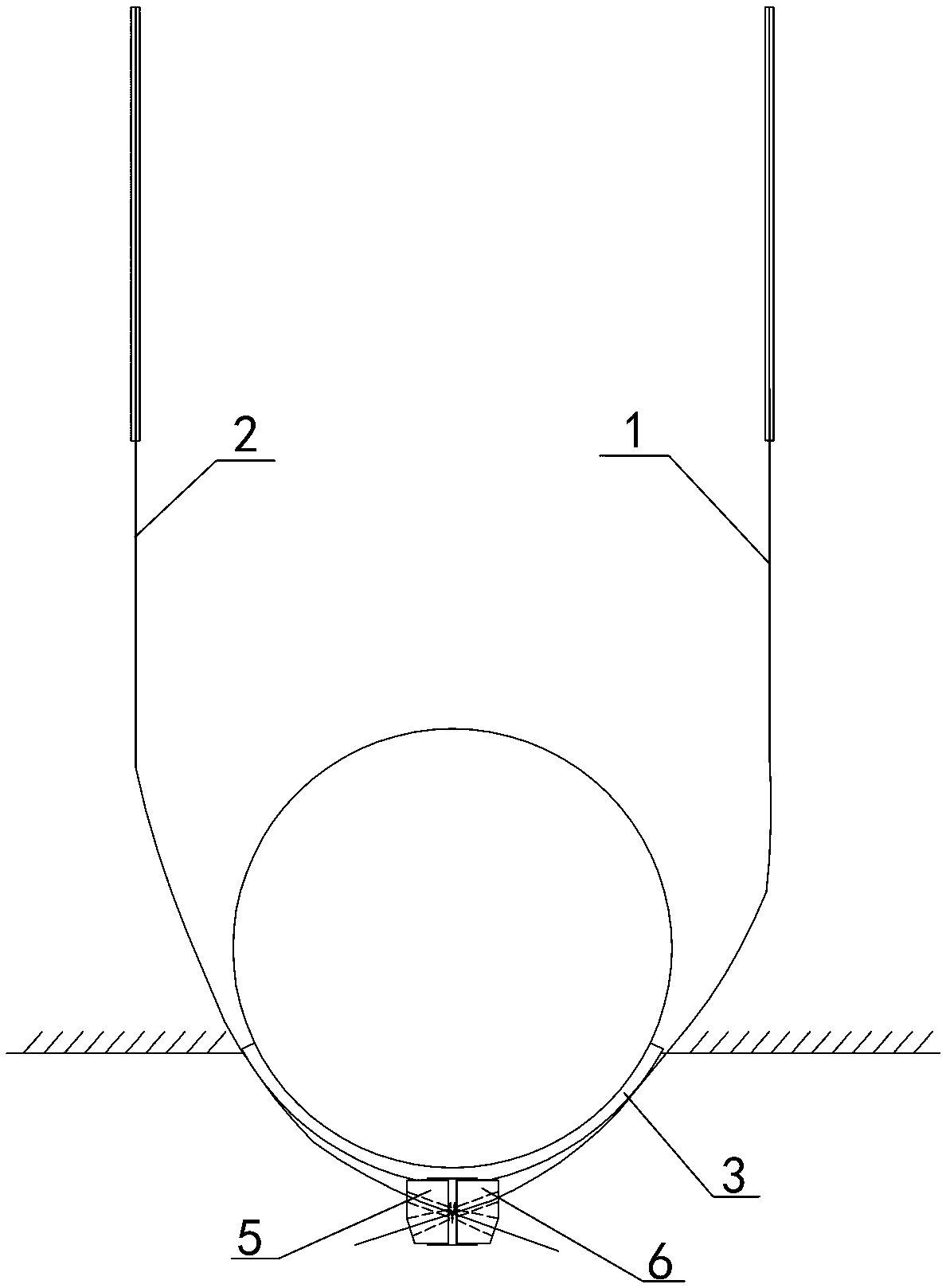

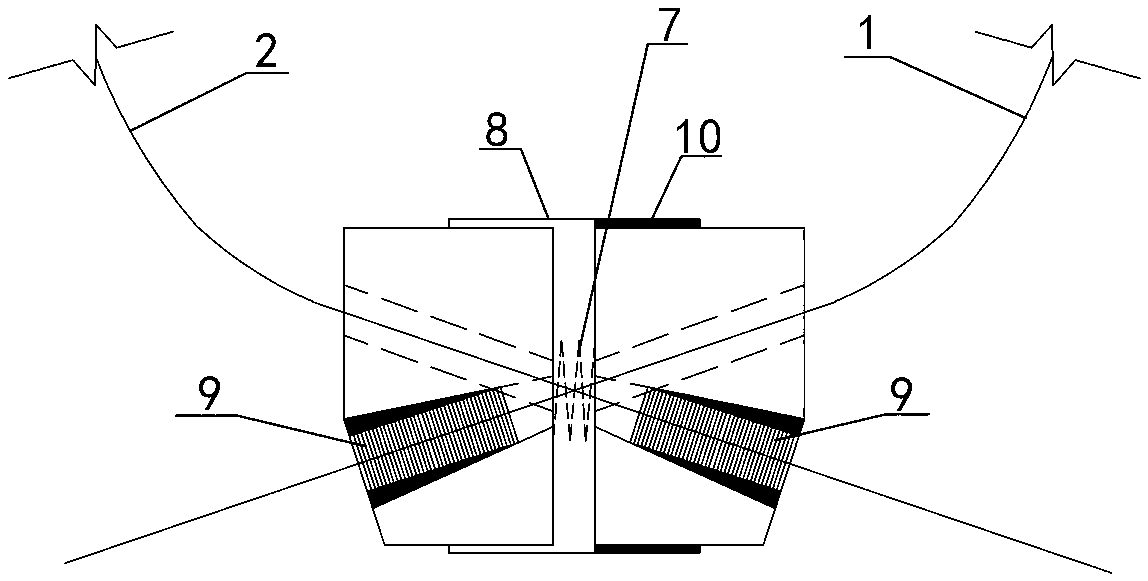

[0041] Examples see Figure 1-9 As shown, a self-balanced multi-bundle prestressed anchor cable connection structure includes a surrounding pile body 15 and a prestressed anchor cable anchored in the soil body, the prestressed anchor cable includes an anchor section and a free section, and the prestress anchor cable The left and right sides of the cable enclosure pile body are anchored symmetrically, wherein the free sections on both sides surround the enclosure pile body at the front side of the enclosure pile body and are cross-fixed by the anchor cable connector. The enclosure pile body 15 and the anchor cable A pile protection backing plate 3 is arranged between the connectors.

[0042] The pile body protection backing plate 3 is a flexible plate made of polystyrene board or rubber plate. The pile body protection backing plate is attached to the outer surface of the surrounding pile body 15, and the pile body protection backing plate isolates the free section and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com