Deep-buried station structure excavated step by step through tunnel-first station-later and arch-first wall-later method and underground excavation construction method of deep-buried station structure

A technology of arch structure and side wall structure, applied in the field of deep buried station structure and its underground excavation method, can solve the problems of mutual influence of excavation, achieve the effects of improving bearing capacity, shortening construction period, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

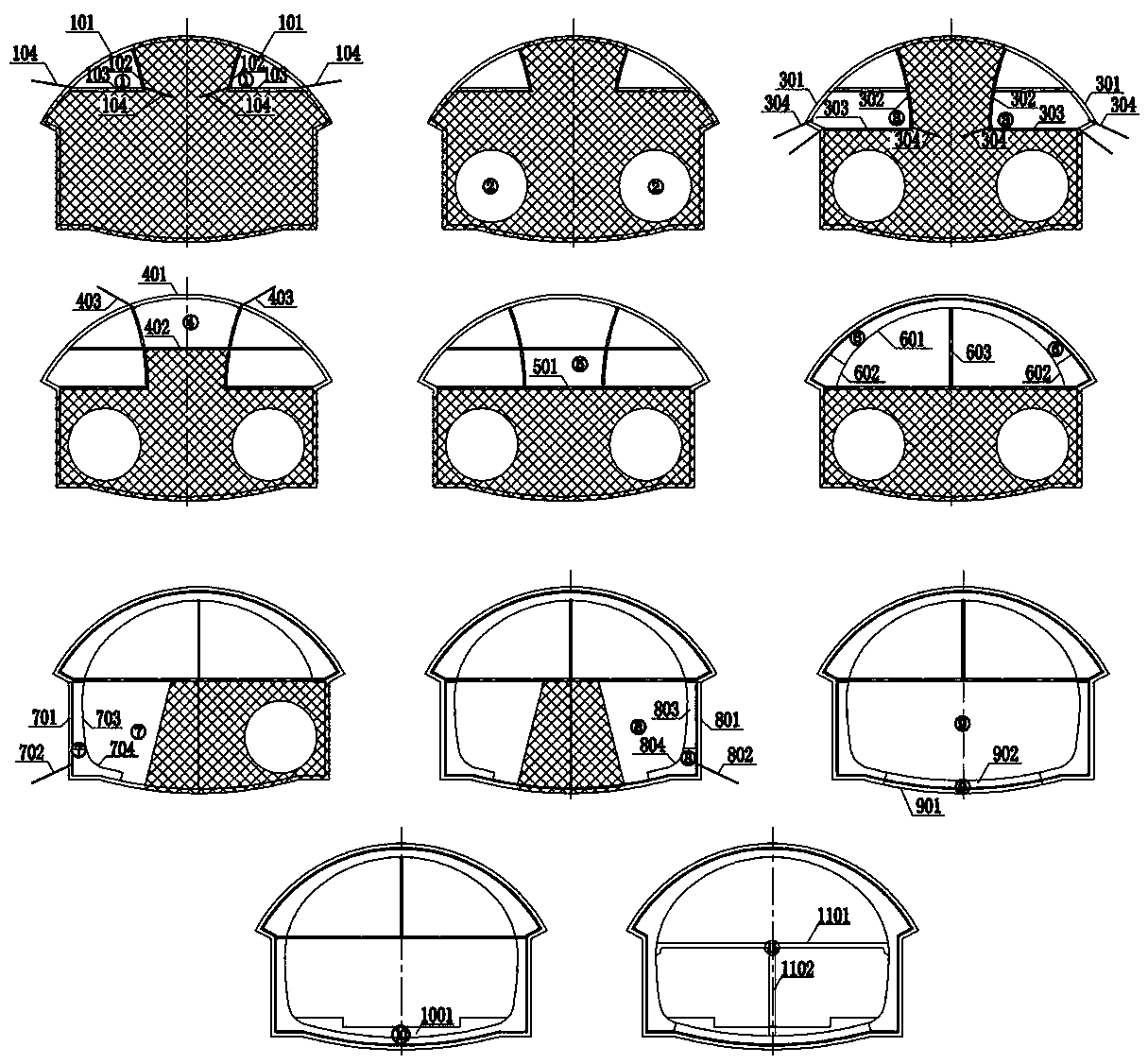

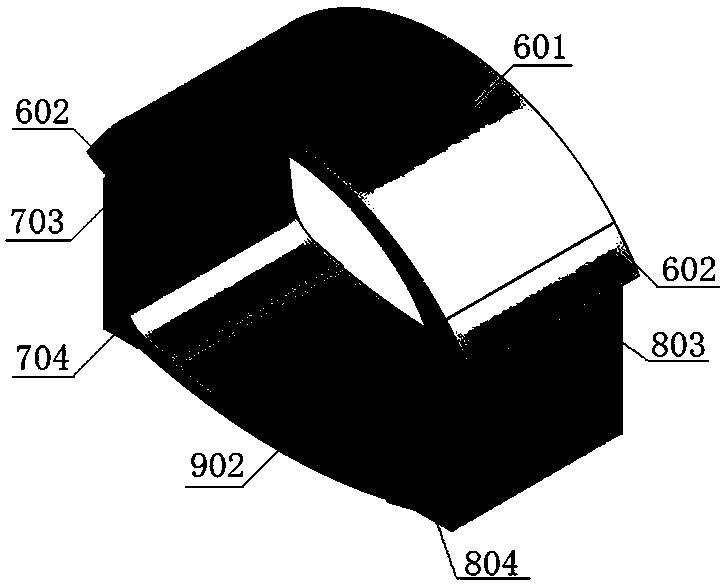

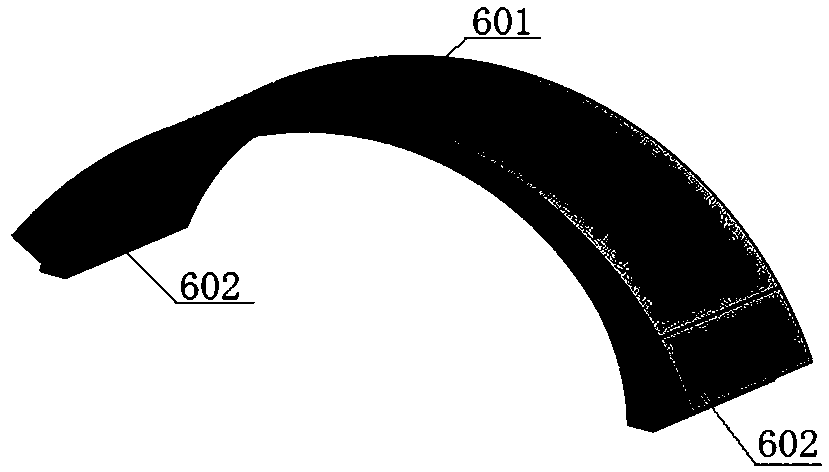

[0070] After the construction of the construction shaft is completed, if figure 1 As shown in Fig. 1, reach the tunnel face of the station, excavate the upper part of the side pilot tunnel, construct the upper steel arch of the side pilot tunnel and spray concrete, carry out the vertical and horizontal steel support of the upper part of the side pilot tunnel, and lay the locking foot anchors at the upper part of the side pilot tunnel Rods; Excavate the lower part of the side pilot tunnel, construct the steel arch frame and spray concrete at the lower part of the side pilot tunnel, implement the vertical and horizontal steel supports at the lower part of the side pilot tunnel, and set the locking anchor rods at the lower part of the side pilot tunnel; excavate the core soil For the upper part, construct the upper steel arch frame of the core soil and spray concrete, apply the horizontal steel support for the upper core soil, and install the anchor bolts for the upper core soil; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com