Steam turbine whole annular blade grid heating blowing sweeping dehumidification experiment system and testing method

An experimental system and steam turbine technology, applied in the field of steam turbine cascade heating, purging and dehumidification experimental system, can solve the problems that have not occurred, and achieve the effect of improving the dehumidification rate, simple operation of the system, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

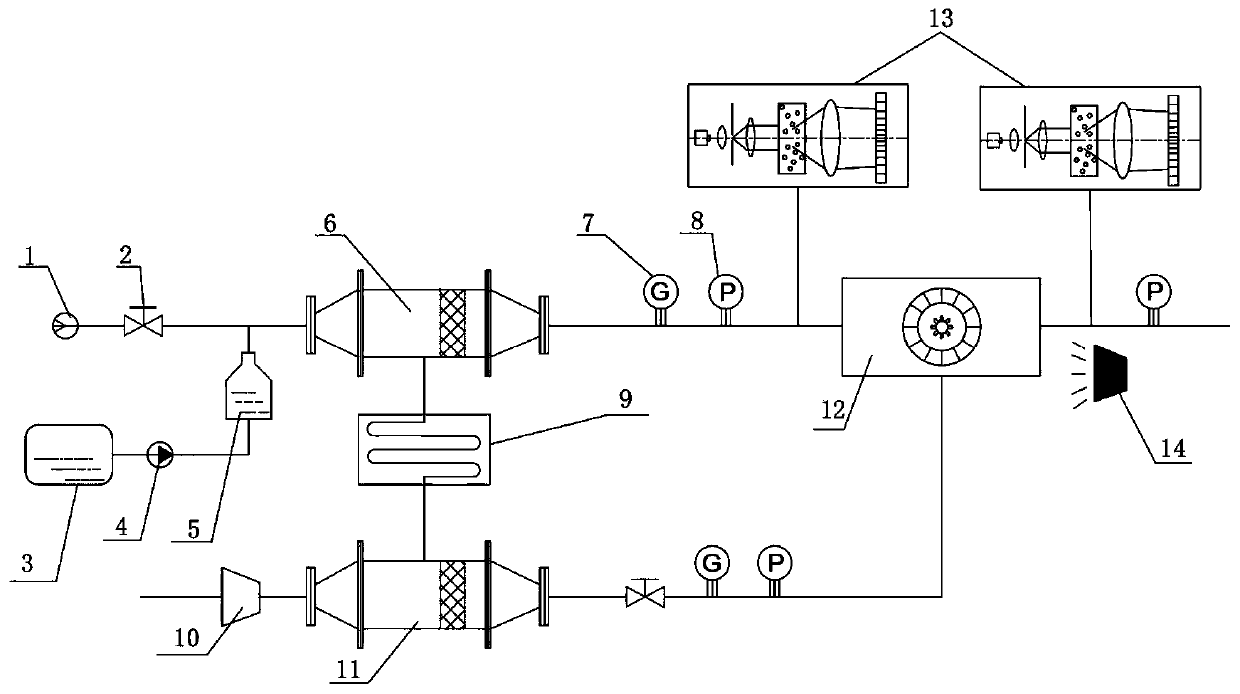

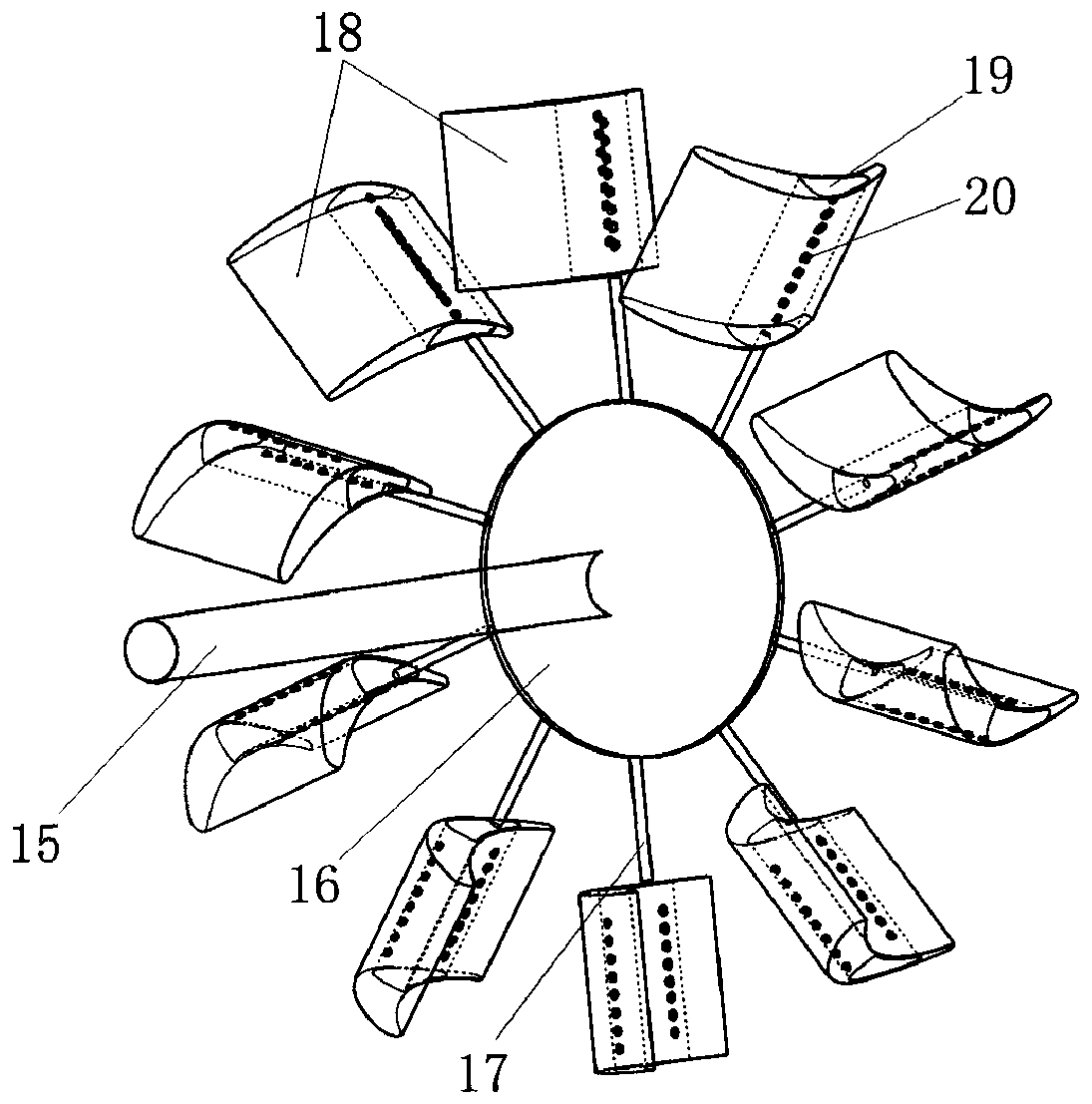

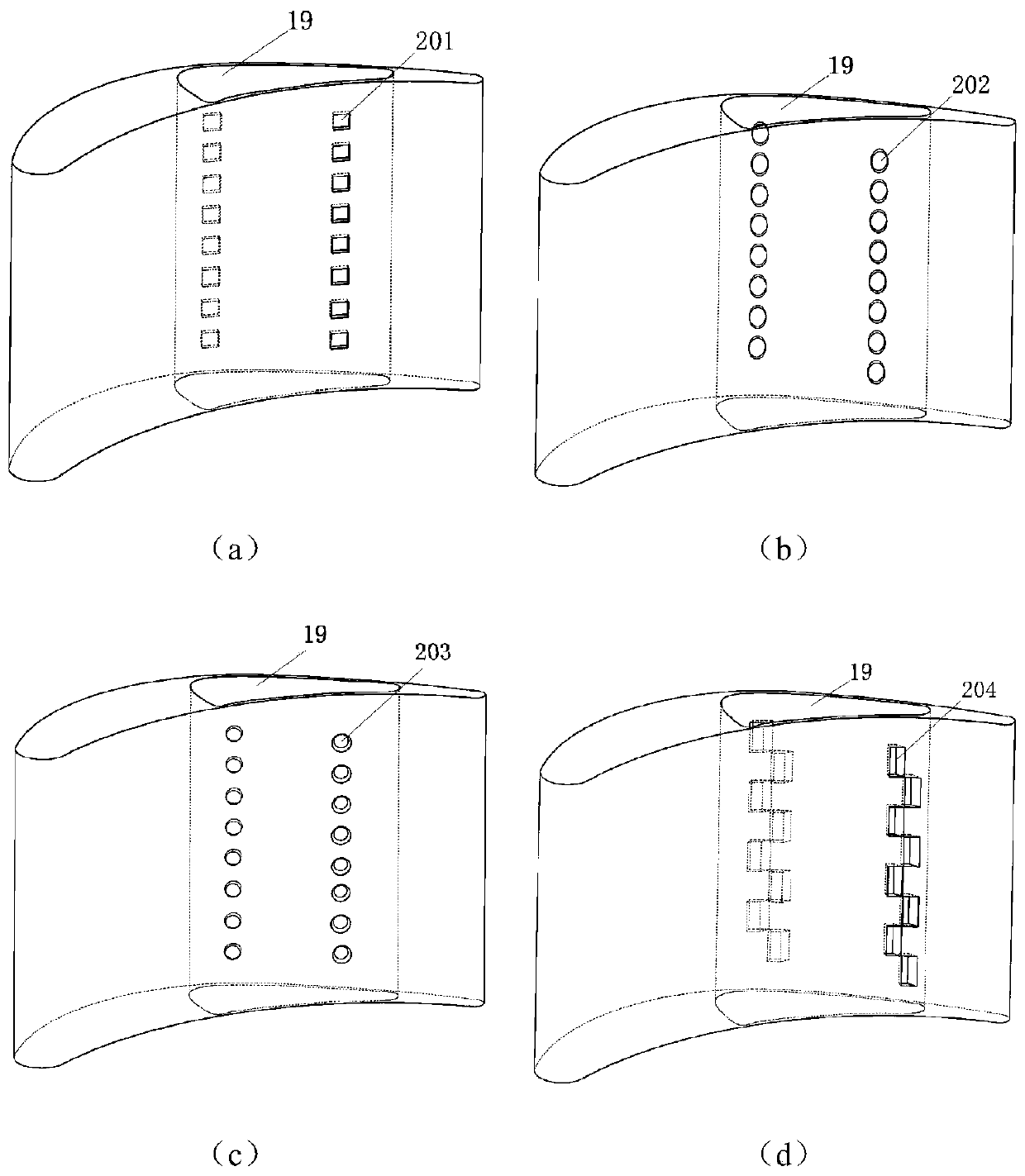

[0036] Reference figure 1 with figure 2 , The present invention provides a steam turbine full circle cascade heating purge and dehumidification experiment system, including mainstream humid air supply pipeline, purge gas supply pipeline, experimental test section 12 and dehumidification test system; mainstream humid air supply pipeline Including air pump 1, regulating valve 2, liquid storage tank 3, water pump 4, atomizing device 5, mainstream gas flow chamber 6 and corresponding supply pipelines; purge gas supply pipeline includes compressor 10, purge gas flow chamber 11. Regulating valve 2 and the corresponding supply pipeline; the experimental test section 12 includes the main flow channel, the purge gas main pipeline 15, the purge gas distribution chamber 16, the purge gas branch pipeline 17 and the full circle cascade; the dehumidification test ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap