System and method for precise hierarchical control of temperature and humidity

A technology of hierarchical control, temperature and humidity, applied in heating and ventilation control systems, air conditioning systems, heating and ventilation safety systems, etc. The effect of energy consumption, precise control of supply air temperature and humidity, and avoidance of reheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

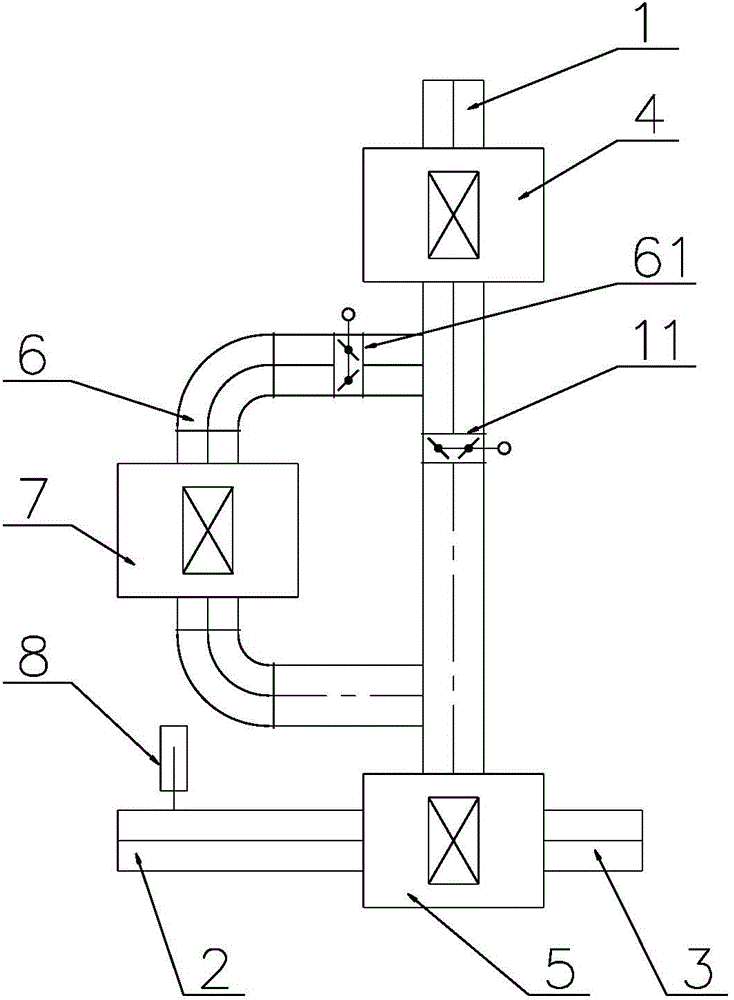

[0021] like figure 1 As shown, the present invention discloses a system for graded control of temperature and humidity accuracy, including a fresh air passage 1, a return air passage 2, an air supply passage 3, a first dehumidification device 4 and a cooling device 5, the fresh air passage 1 and the The return air passage 2 merges and connects to the air supply passage 3, the first dehumidification device 4 is arranged in the fresh air passage 1, and the cooling device 5 is arranged at the output end of the return air passage 2 and the air supply passage. Between the input ends of the air passage 3, this system also includes a fresh air passage branch 6, the input end of the fresh air passage 6 is set on the fresh air passage 1, and is arranged behind the output end of the first dehumidification device 4 , the output end of the fresh air channel branch 6 is connected to the end of the fresh air channel 1 , and the fresh air channel branch 6 is provided with a second dehumidifi...

Embodiment 2

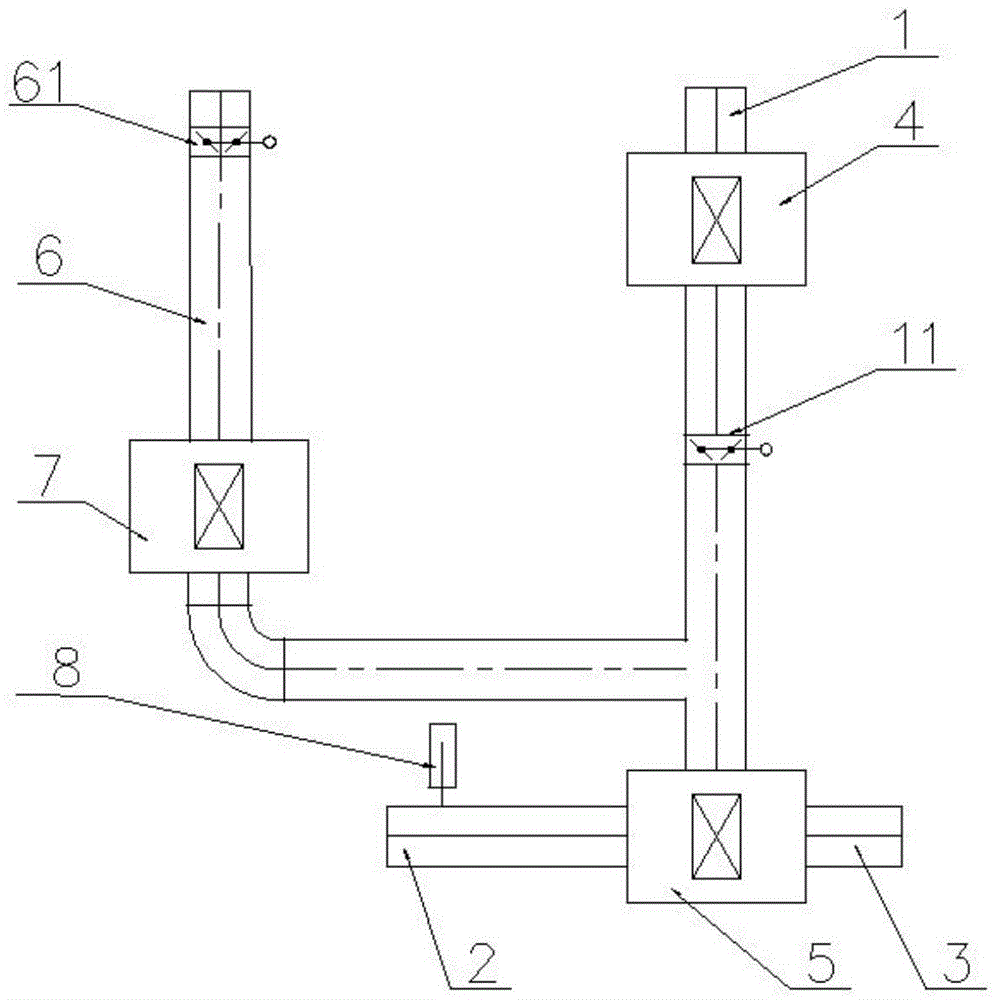

[0023] like figure 2 As shown, the present invention discloses a system for graded control of temperature and humidity accuracy, including a fresh air passage 1, a return air passage 2, an air supply passage 3, a first dehumidification device 4 and a cooling device 5, the fresh air passage 1 and the The return air passage 2 merges and connects to the air supply passage 3, the first dehumidification device 4 is arranged in the fresh air passage 1, and the cooling device 5 is arranged at the output end of the return air passage 2 and the air supply passage. Between the input ends of the air channel 3, the system also includes a fresh air channel branch 6, the input end of the fresh air channel branch 6 is directly connected with the external fresh air, and the output end of the fresh air channel branch 6 is connected to the fresh air channel 1 At the end, the fresh air channel branch 6 is provided with a second dehumidification device 7 .

[0024] As a preferred mode of Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com