Impeller for forward centrifugal fan

A technology of centrifugal fans and impellers, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., which can solve the difficulties in processing and installing semi-conical impellers, the performance degradation of conical impeller fans, and the impact on fans. Efficiency and noise problems, to achieve the effect of weakening the shedding phenomenon, reducing the number of blades and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

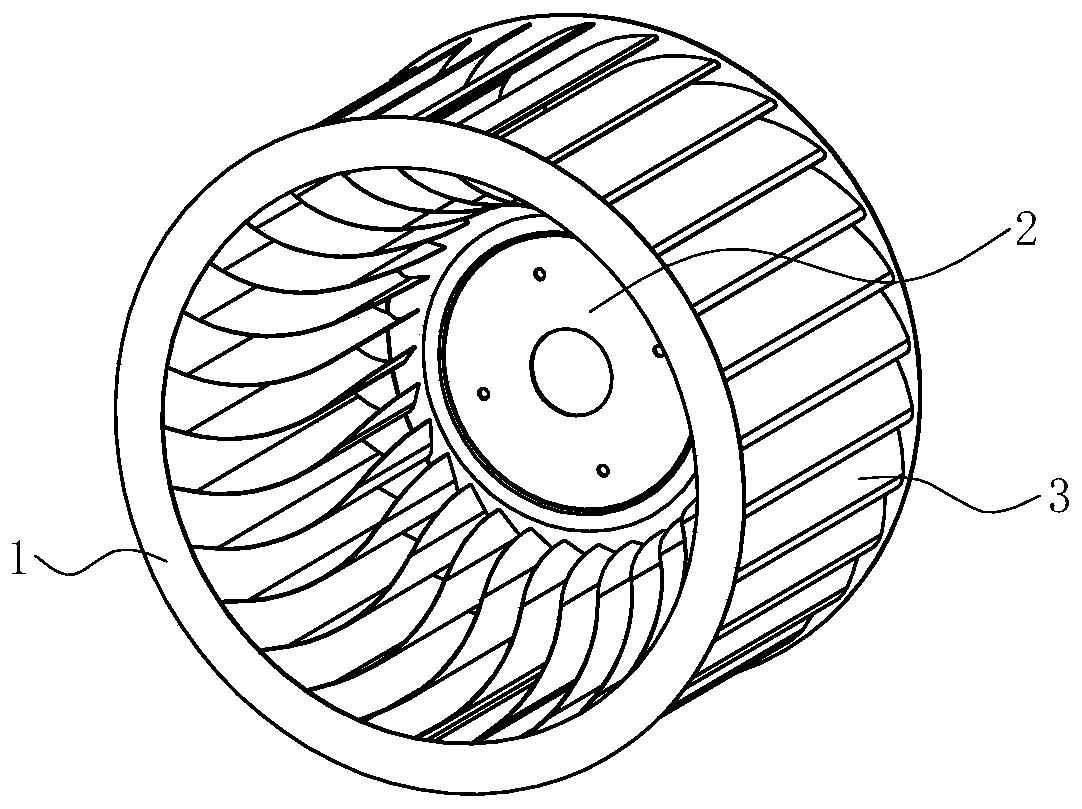

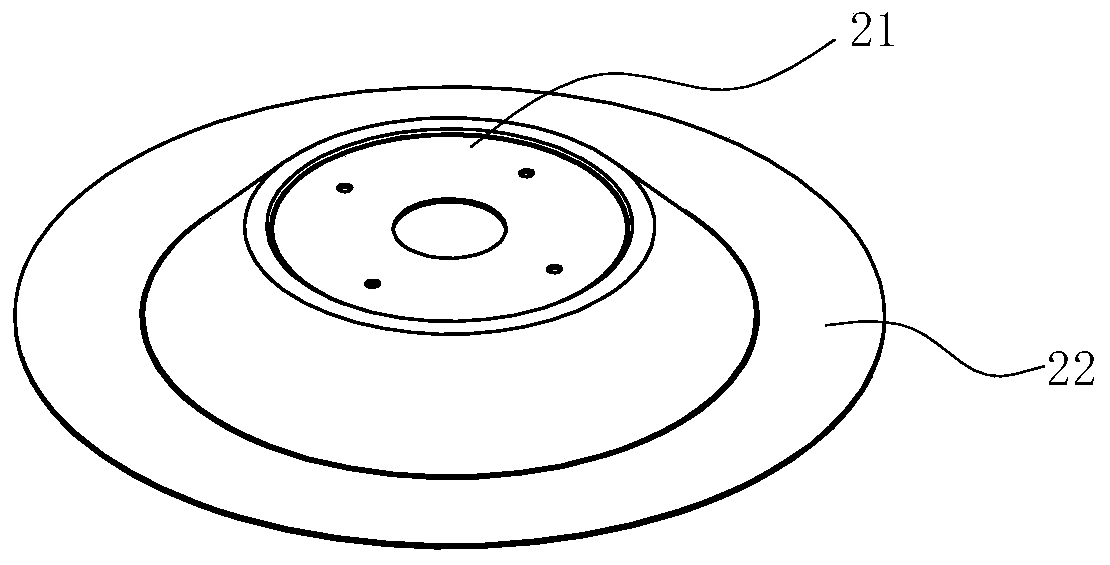

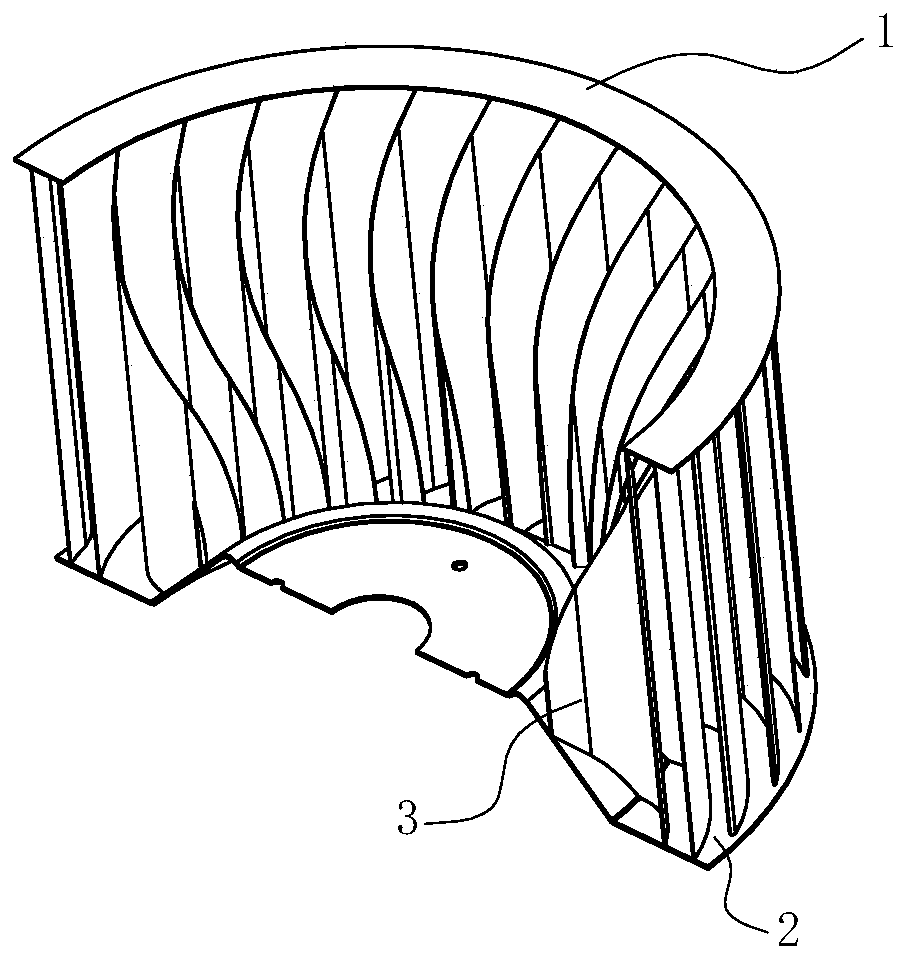

[0023] See figure 1 with figure 2 , An impeller for a forward centrifugal fan, comprising a front disc 1, a rear disc 2, and a plurality of blades 3 arranged between the front disc 1 and the rear disc 2, and each blade 3 is evenly arranged in the circumferential direction. The centrifugal fan can be a fan used for ventilation equipment such as range hoods, HVAC, etc. The front disc 1 has a circular ring shape, and the rear disc 2 includes an inner boss 21 and an annular ring 22 located on the outer periphery of the boss 21. The boss 21 has a cone shape and is used for mounting a motor for driving the impeller to rotate. The front disc 1 and the rear disc 2 are mechanically connected to the blade 3 respectively. The projection of the axis of the impeller 3 in the axial direction is the center point O.

[0024] See Figure 7 If the number of blades 3 is too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com