Clean pipeline drying system

A drying system and pipeline technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of cross-infection of patients, secondary air pollution of lumen-type equipment, and no air heating treatment, etc., to achieve The effect of prolonging the practical life, reducing the probability of secondary pollution, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

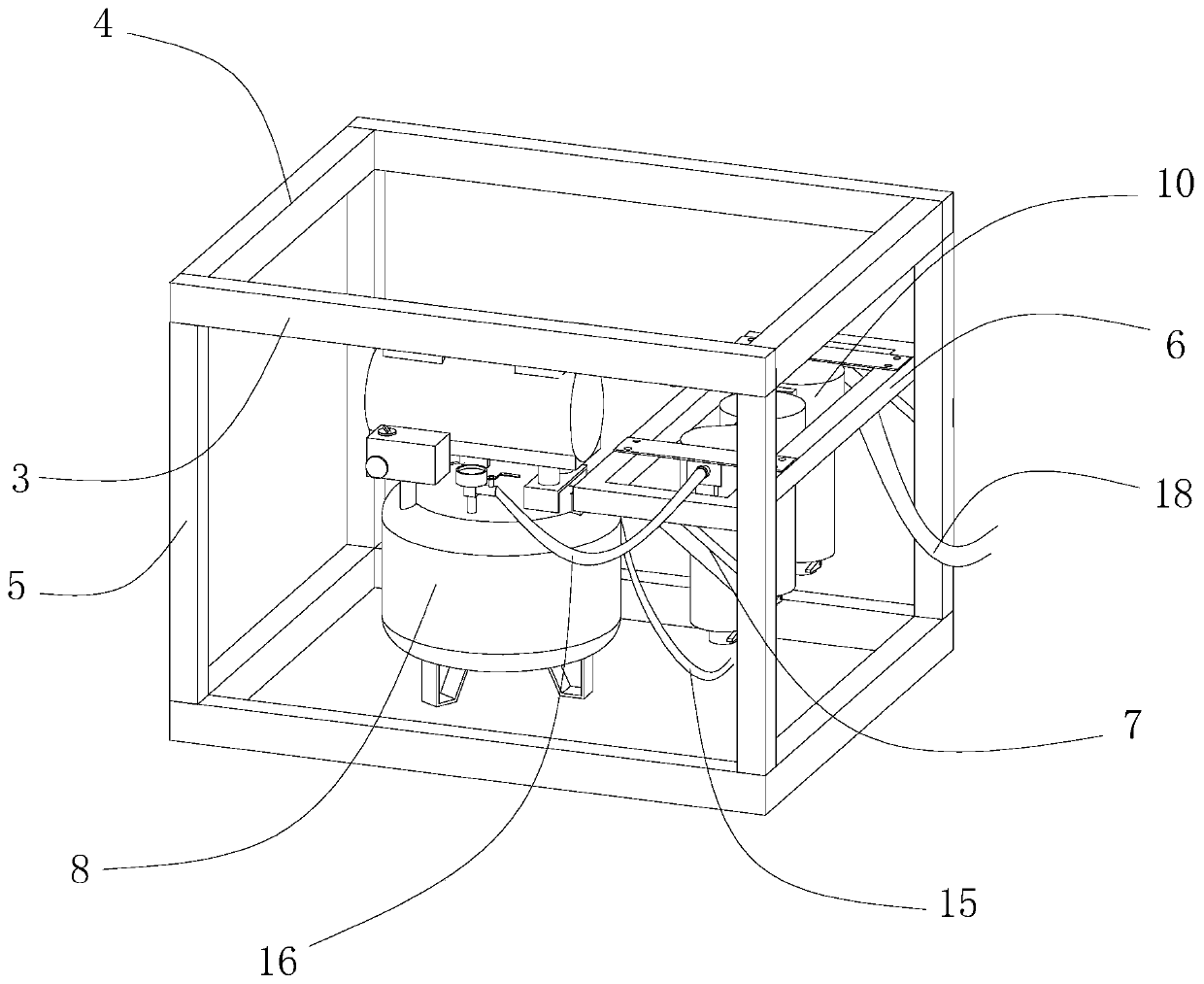

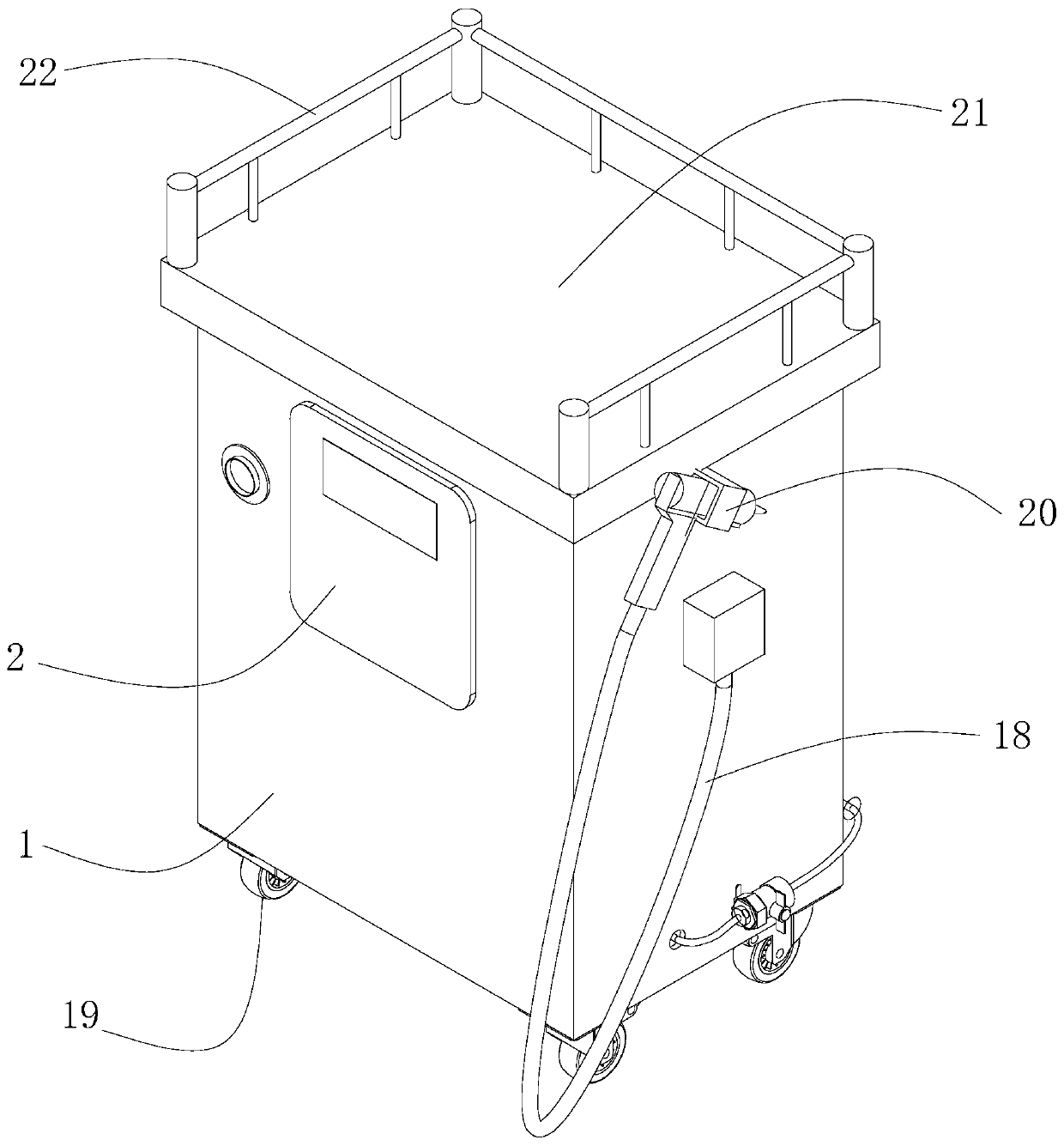

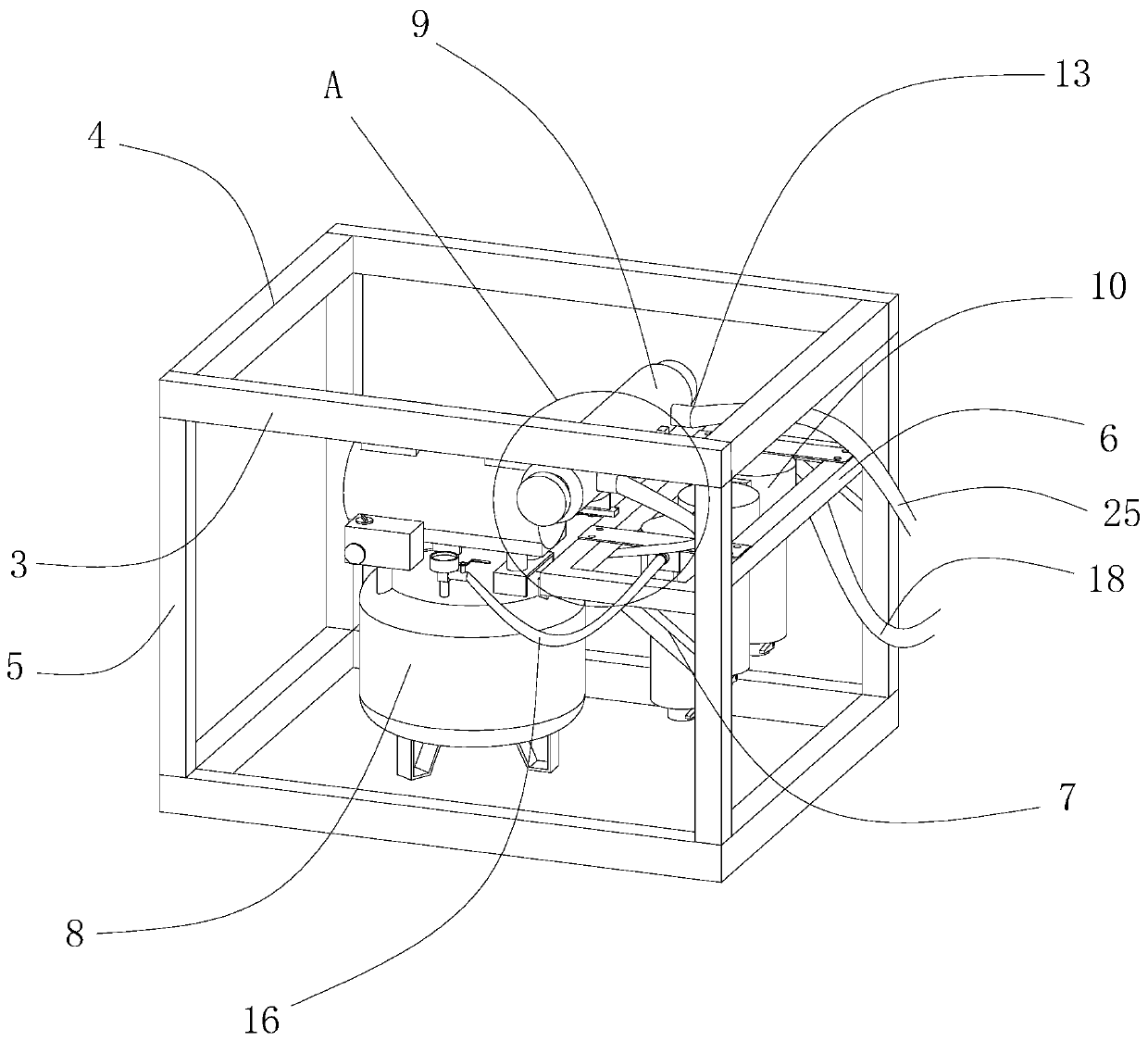

[0037] to combine figure 1 and figure 2It can be seen that a clean pipeline drying system includes a rectangular support frame assembled by two long frame bars 3, two short frame bars 4 and four corner connecting rods 5, the corner connecting rods 5, long frame bars 3 and short The frame bars 4 are perpendicular to each other; a rectangular mounting frame 6 perpendicular to the corner connecting rod 5 is fixed between the two corner connecting rods 5, and the bottom of the rectangular mounting frame 6 is welded with a support frame 7; Compressor 8, air cleaning device; housing 1 is provided outside the support frame, control panel 2 is provided on housing 1, conductive mute wheel 19 is provided below housing 1, pressure gun 20 is connected to housing 1, pressure gun A heating wire electrically connected to the control panel 2 is provided in the 20 , which is not shown in the drawing, and a working platform 21 and a railing 22 are provided on the upper surface of the casing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com