Tipping paper perforating device

A technology of punching device and tipping paper, which is applied in the direction of measuring device, transportation and packaging, instruments, etc., to achieve the effect of improving accuracy, good sharpness, and avoiding image ghosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiment of the present invention solves the technical problem that only tipping paper products can be punched in the prior art by providing a tipping paper punching device, and realizes that image samples can be provided for surface quality analysis of tipping paper products technical effect.

[0019] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

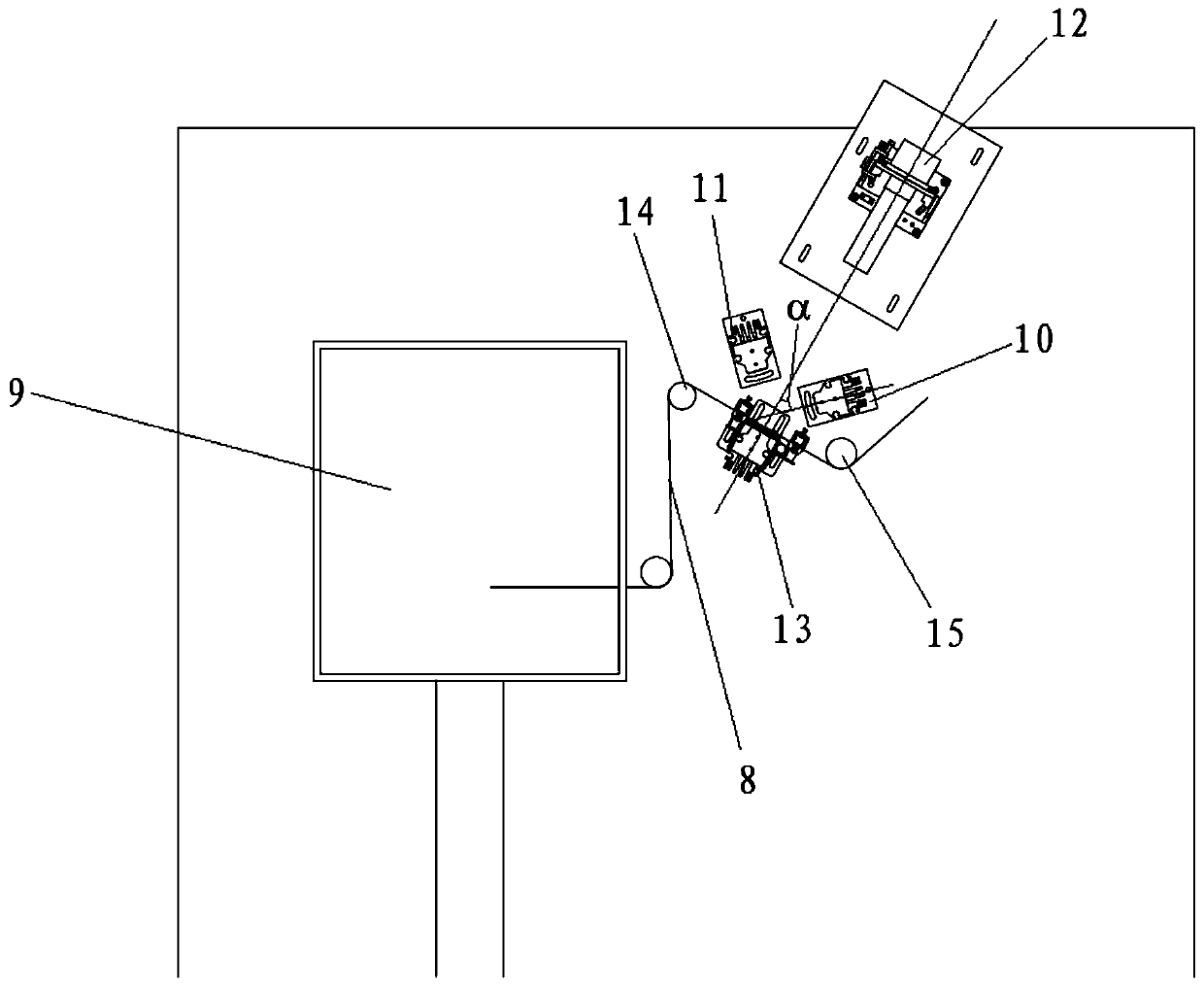

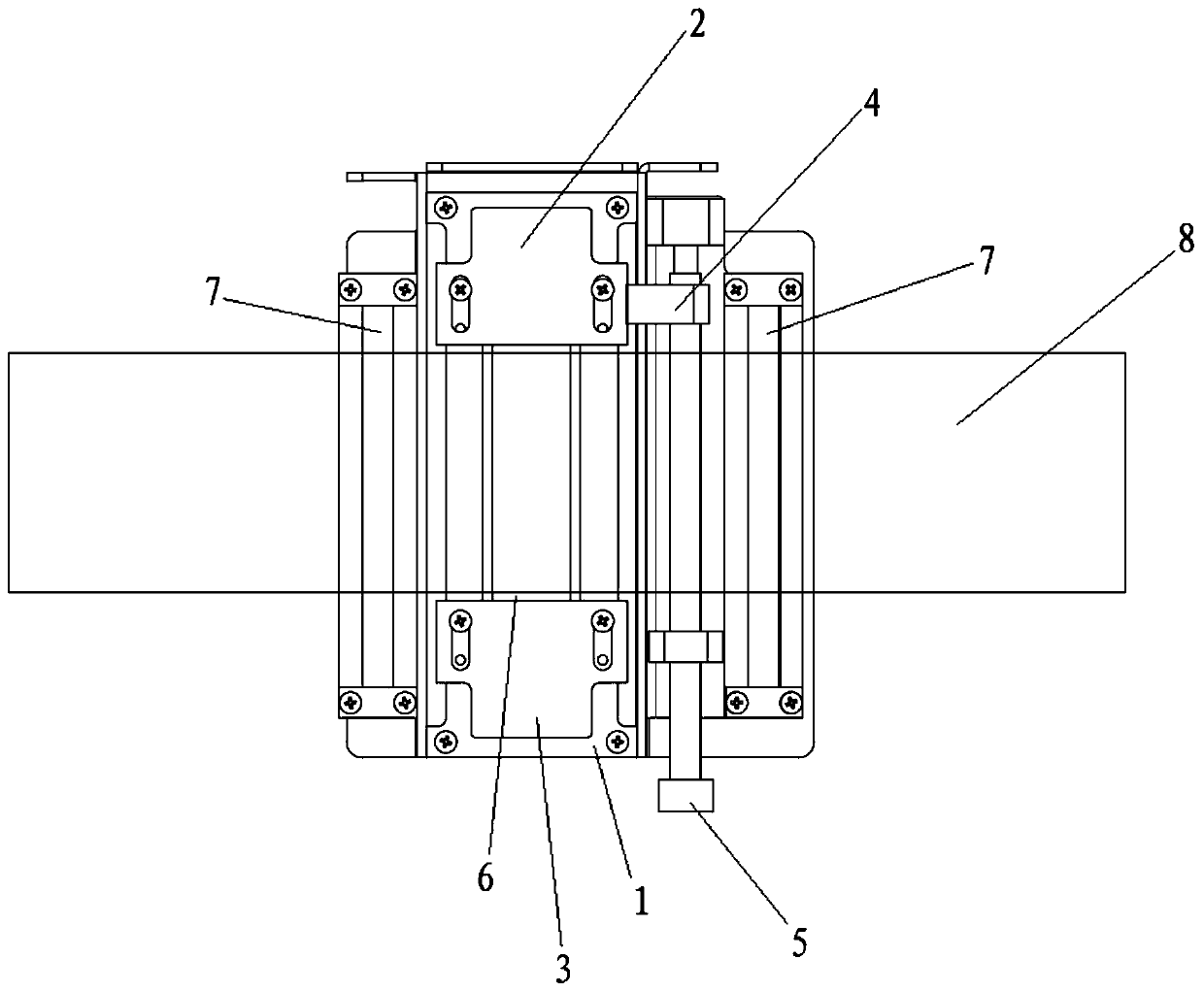

[0020] Set the main light source at the paper output of the punching device and in the path of the paper. When the punched tipping paper product arrives at the main light source, the camera equipment can obtain the surface photo of the tipping paper product, and can send the obtained surface photo to the processor to provide a basis for the surface quality analysis of the tipping paper product . In addition, both the first auxiliary light source and the second auxiliary light source face the main light source, and the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com