Grinding wheel for automatically grinding diamonds

A diamond and grinding disc technology, which is applied in the direction of abrasive materials, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient uniformity, easy falling off of the cutter head, and difficulty in controlling the uniformity of grinding, so as to achieve good social and economic benefits. The effect of saving welding time and cost, and saving time for changing abrasive tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

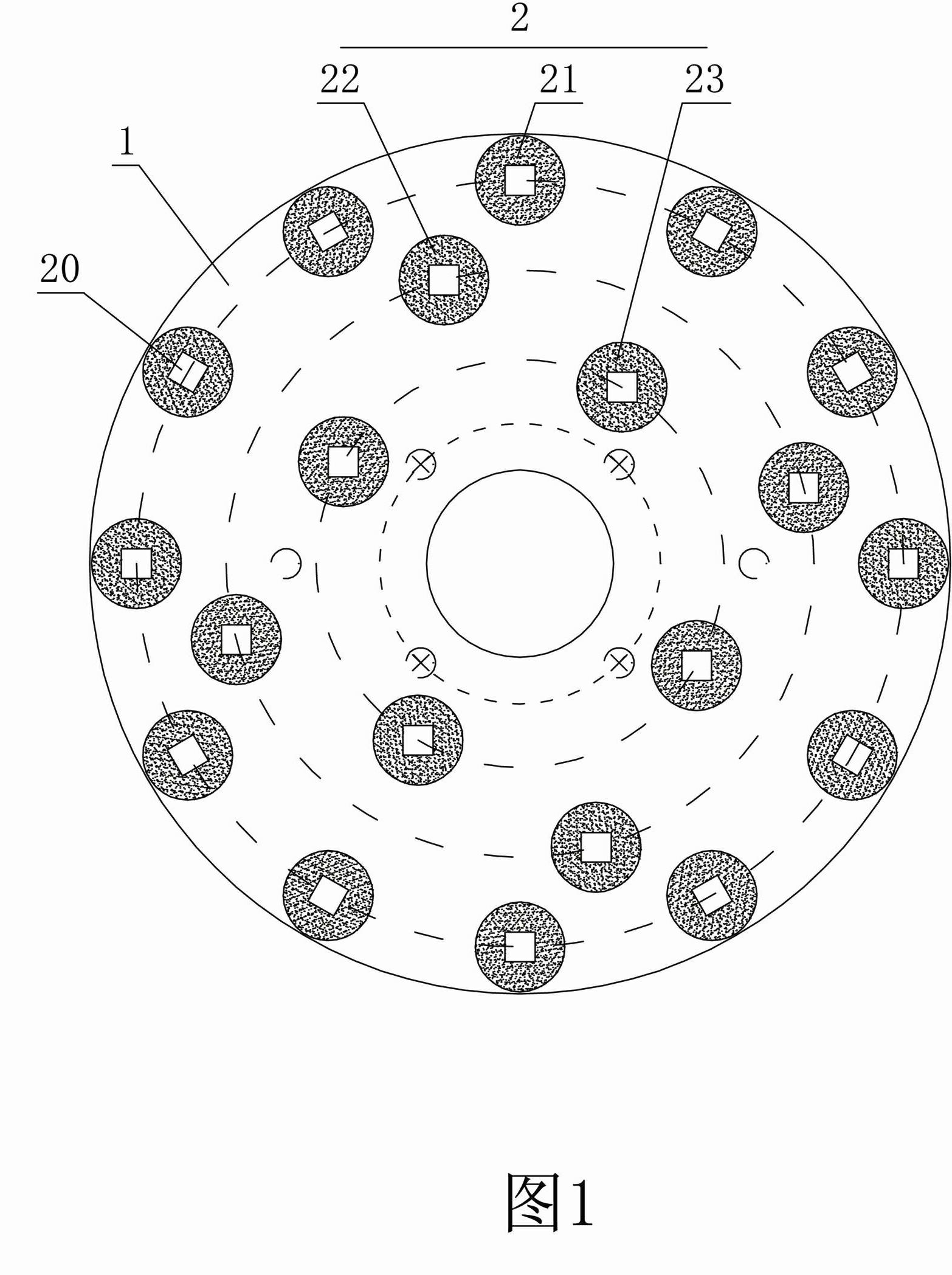

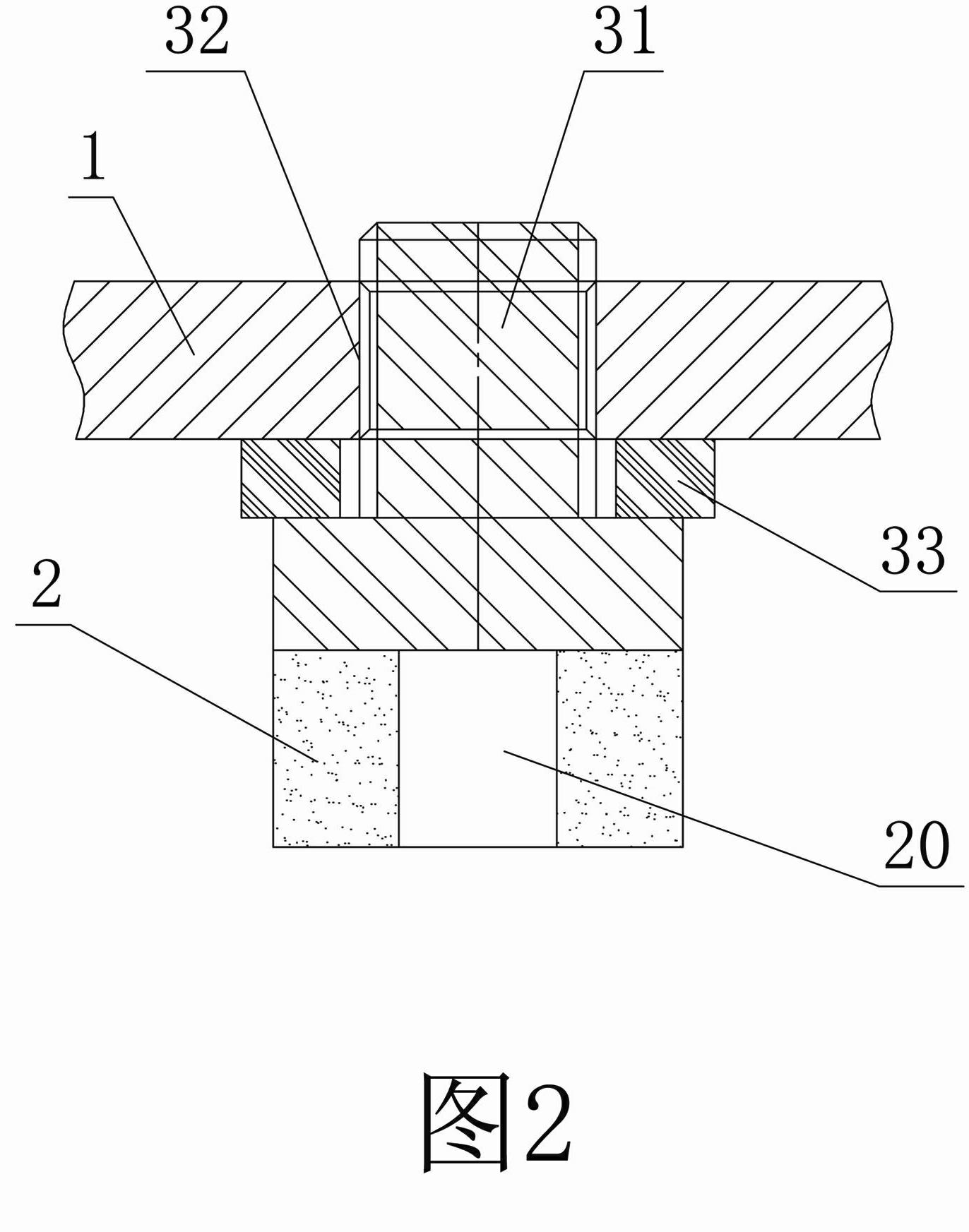

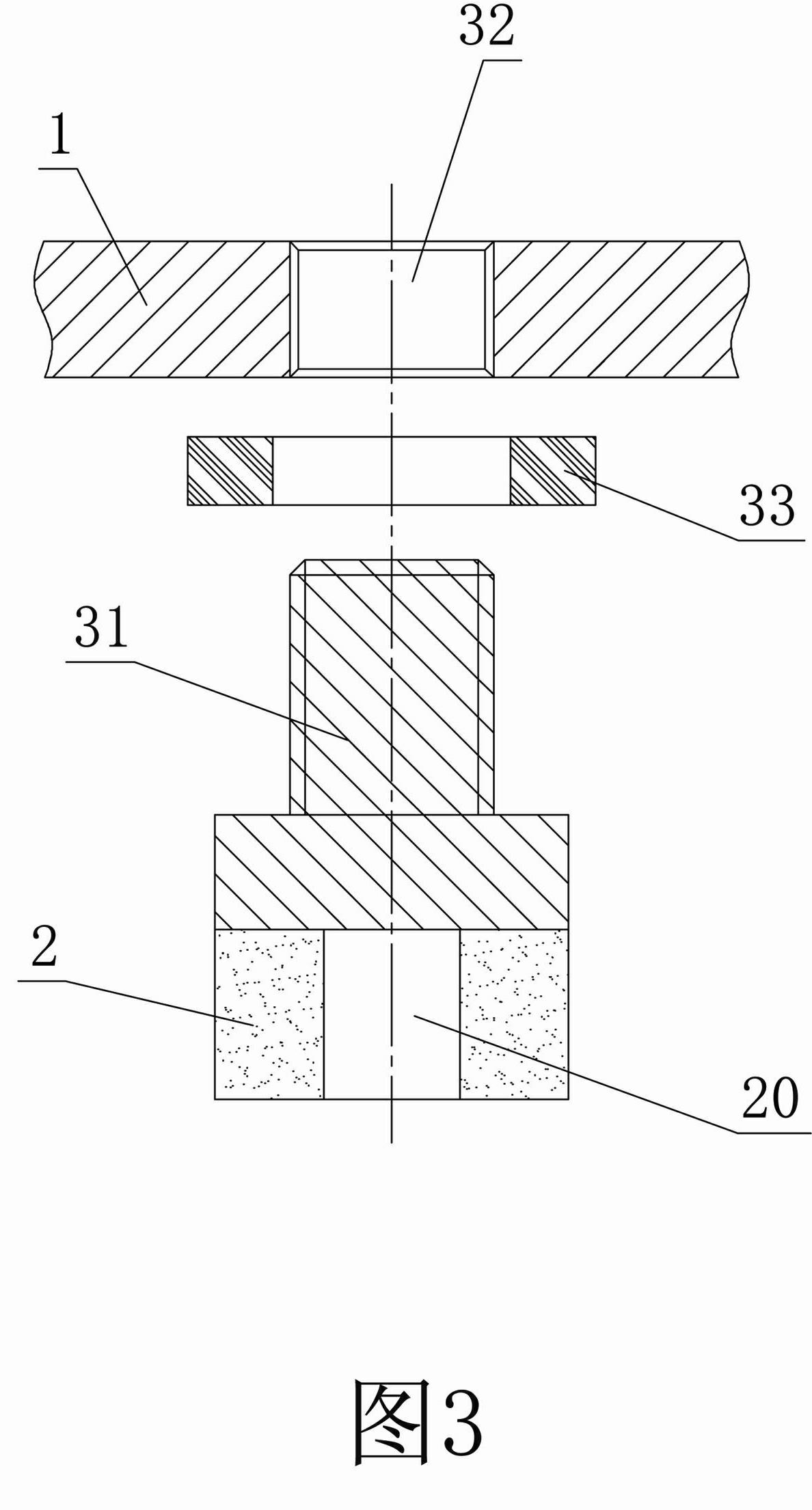

[0020] refer to Figure 1 to Figure 3 . An automatic diamond grinding disc, including a disc body 1 and a cutter head 2 fixedly installed on the disc body 1, the back of the cutter head 2 is fixedly welded with a bolt 31 by a high-frequency welding machine, and the corresponding part of each cutter head 2 The disc body 1 is correspondingly provided with threaded holes 32 ; the cutter head 2 is detachably fixed on the disc body 1 through bolts 31 , threaded holes 32 and anti-loosening spring pads 33 . The cutter head 2 is detachably locked on the disc body 1 by bolts 31 and threaded holes 32, which can prevent the cutter head 2 from accidentally falling off during the grinding process, eliminate potential safety hazards, and ensure the safety of the grinding disc. After grinding the diamond material layer of the cutter head, just unscrew the remaining cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com