Conger eel processing and washing device

A cleaning device and conger eel technology, applied in fish processing, fish cleaning/descaling, slaughtering, etc., can solve the problems of backward conger eel processing technology, increased production cost, and low work efficiency, so as to improve labor efficiency and improve efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

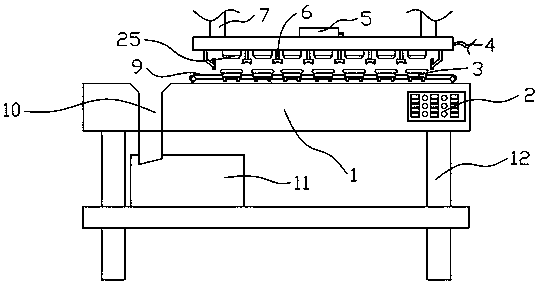

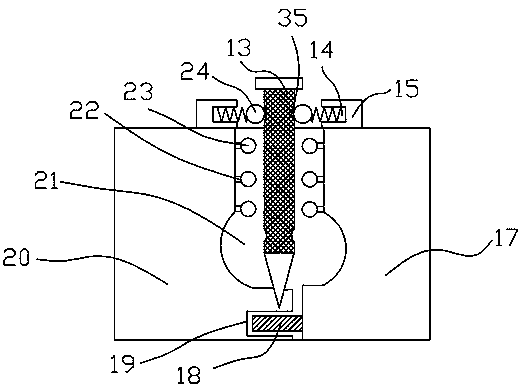

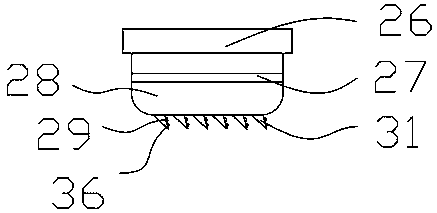

[0023] Such as Figure 1-6 As shown, the sea eel processing and cleaning device includes a base 1, a control panel 2 is provided on the right side of the base 1, a support foot 12 is provided under the base 1, and a lower ring guide 9 and a lower ring guide are provided on the upper surface of the base 1 A corresponding upper ring rail 8 is provided above 9, which is connected to the wall by a connecting rod 7, a motor 5 is provided on the surface of the upper ring rail 8, and a water spray assembly 6 is provided on the upper ring rail 8. The component 6 is composed of a plurality of nozzles, and a main water inlet pipe 4 is provided at the right end of the upper ring rail 8. Start the motor, the upper ring guide and the lower ring guide will rotate accordingly. During the rotation, the slaughter will be carried out. The main water inlet pipe enters the water, and the water spray assembly will spray water at the same time as the slaughter. The one-step cleaning also avoids the...

Embodiment 2

[0032] Such as Figure 1-6 As shown, the working principle of the conger eel processing and cleaning device is: the motor 5 is turned on, the clamping device 3 of the lower ring guide 9 and the electric knife set 25 of the upper ring guide 8 move, so that the clamping device can be used in the slaughter process of the eel 3 Clamp the eel, and pass the electric knife set 25 through the gap between the first splint 20 and the second splint 17 of the eel, thereby slaughtering the eel, and the device can slaughter multiple eels at the same time, speeding up Production speed, after the slaughter is over, 60% of the water spray can be used to initially clean the conger eels, which improves the efficiency of slaughtering conger eels.

[0033] The conventional technology in the above-mentioned embodiment is the prior art known to those skilled in the art, so it will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com