Silica-based micro display screen and preparation method thereof

A display, silicon-based technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as physical bottlenecks in manufacturing technology, and achieve the effect of preventing optical crosstalk and high pixel density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and effect of the present application more clear and definite, the present application will be further described in detail below with reference to the accompanying drawings and examples.

[0031] The invention provides a silicon-based micro-display screen and a preparation method thereof, which are mainly used to solve the problems that the existing OLED vapor deposition patterning technology has physical limits and high pixel density patterning is difficult.

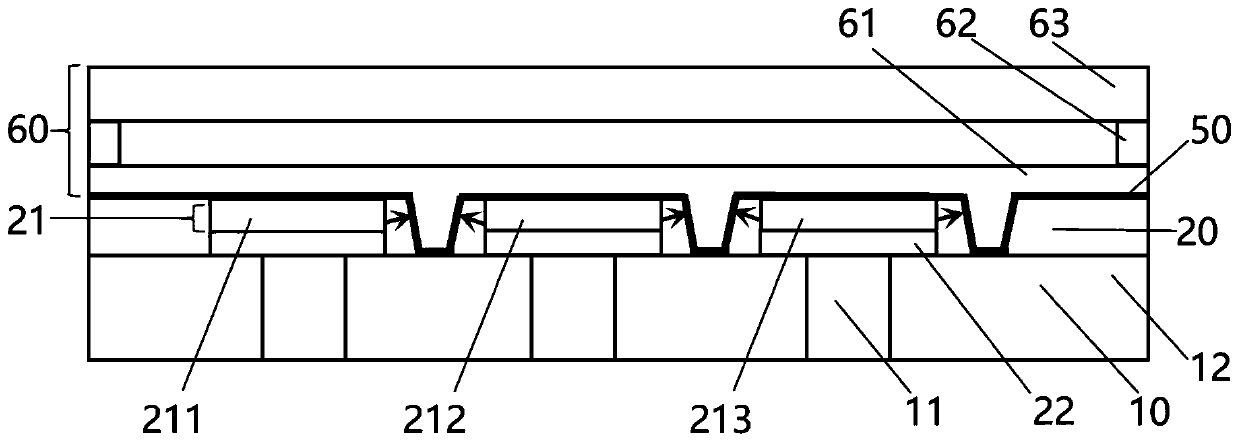

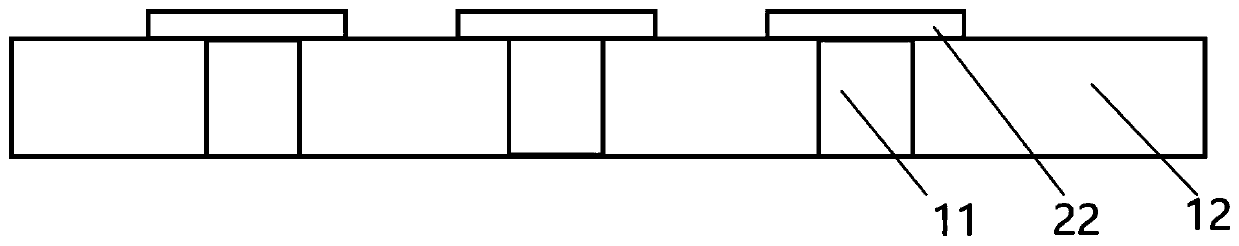

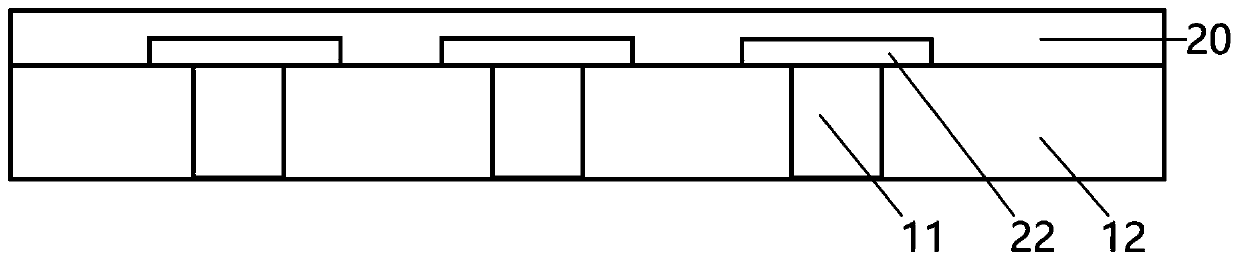

[0032] Such as figure 1 As shown, the silicon-based micro display screen includes: a driving backplane 10, a pixel definition layer 20 formed on the driving backplane 10, a light emitting layer 21 formed in the pixel definition layer 20, and a The encapsulation layer 60 of the light emitting layer 21 and the metal reflective layer 50 formed between the light emitting layer 21 and the encapsulation layer 60 .

[0033] The driving backplane 10 includes a silicon sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com