Pixel structure of cmos image sensor and its manufacturing method

A technology of image sensor and pixel structure, applied in the direction of radiation control devices, etc., can solve problems such as sensitivity, resolution and definition deterioration, pixel optical crosstalk, chip performance deterioration, etc., to improve optical resolution and sensitivity , Improve light absorption, improve performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

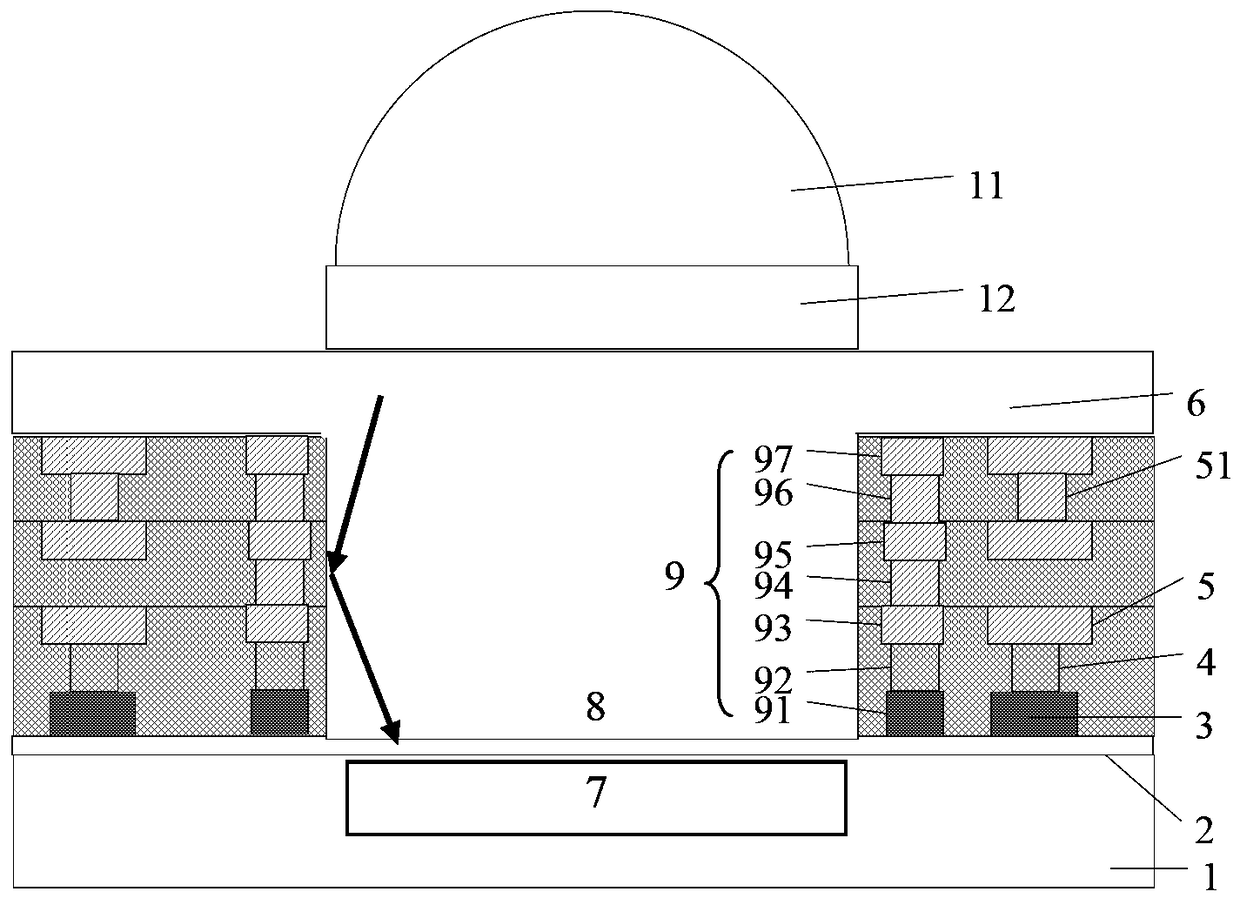

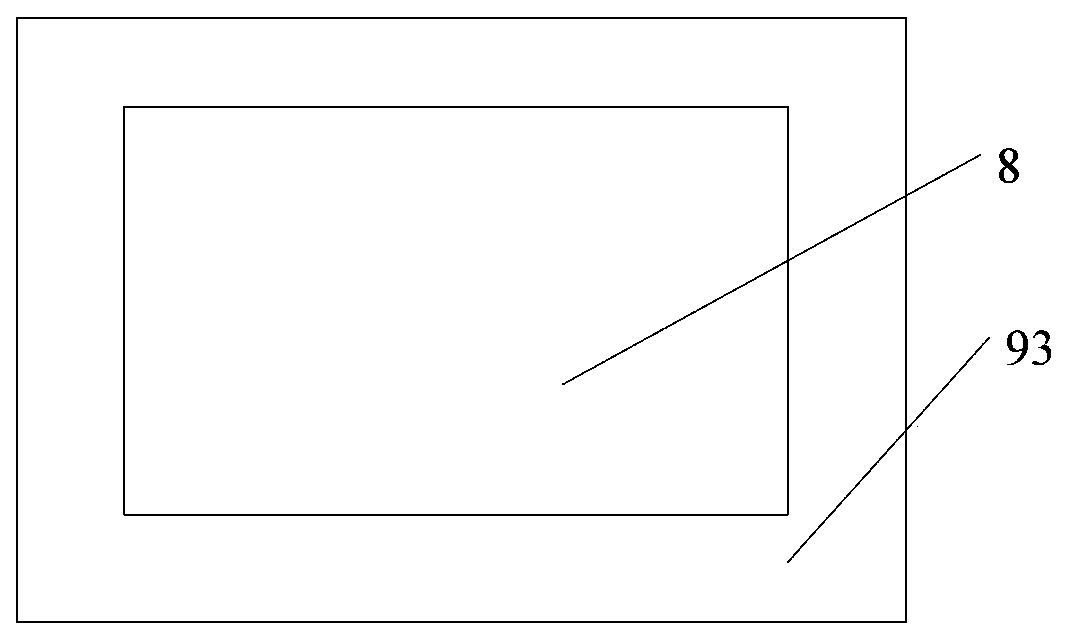

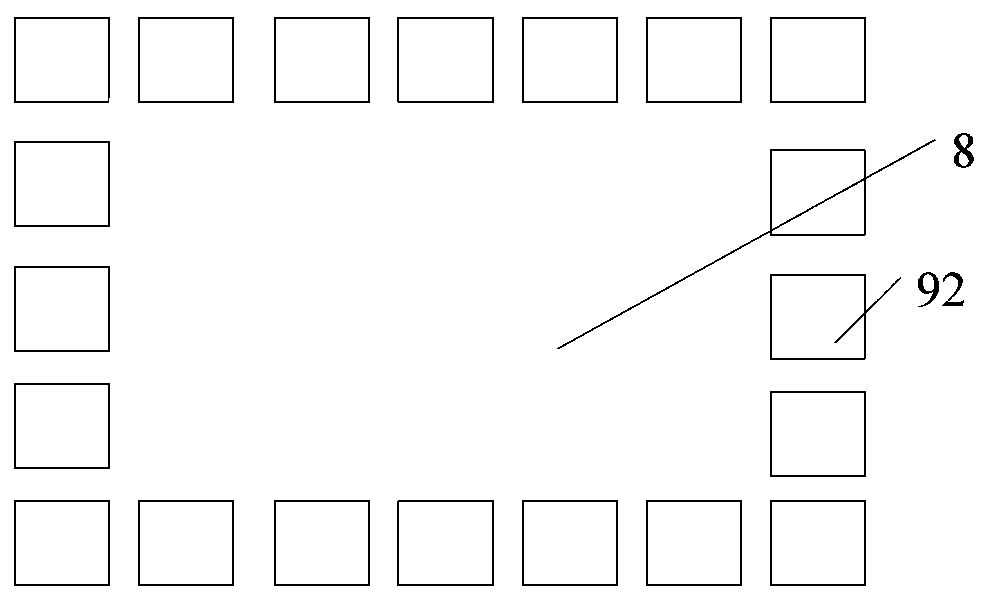

[0041] see figure 1 , the pixel structure of the CMOS image sensor includes a photodiode 7 and a multilayer structure (for standard CMOS devices) on the silicon substrate 1, and there is also a layer between the silicon substrate 1 and the multilayer structure in this embodiment Gate oxide layer 2, wherein the multi-layer structure includes from bottom to top the first polysilicon layer 3, the W contact hole layer 4, the Cu metal interconnection layer 5 and the first via hole layer 51, the interconnection dielectric layer (not marked), a deep groove 8 is arranged above the photodiode 7, and a light reflection shielding layer 9 is also provided in the side wall medium of the deep groove 8, and the distance between the light reflection shielding layer 9 and the side wall of the deep groove 8 is 0.1um , it completely surrounds the deep trench 9, and it includes a second polysilicon layer 91, a second contact hole layer 92, and a second metal interconnection layer A that are conti...

no. 2 example

[0052] In this embodiment, the light reflection shielding layer is a metal layer surrounded by metal, and is arranged vertically from the grid oxide layer upwards continuously to form a whole.

[0053] see Figure 4a to Figure 4d , the manufacturing method of the pixel structure of the CMOS image sensor of the present embodiment comprises the following steps:

[0054] Step S101: arranging photodiodes and multilayer structures for standard CMOS devices on a silicon substrate, and utilizing standard CMOS processes to realize photodiodes and multilayer structures;

[0055] Step S102: using a photolithography process to realize the through hole 101 on the top layer of the multilayer structure and the hole groove 102 for accommodating the light reflection shielding layer;

[0056] Step S103: Realize the groove 103 for accommodating metal wiring in the first metal interconnection layer on the top layer of the multilayer structure by using a photolithography process;

[0057] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com