Loudspeaker with novel double-magnetic structure

A magnetic structure and loudspeaker technology, applied in the directions of loudspeakers, sensors, electrical components, etc., can solve the problems of insufficient sound performance range, poor coordination of high and low frequencies, etc., to achieve good consistency, excellent electro-acoustic performance, Excellent structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

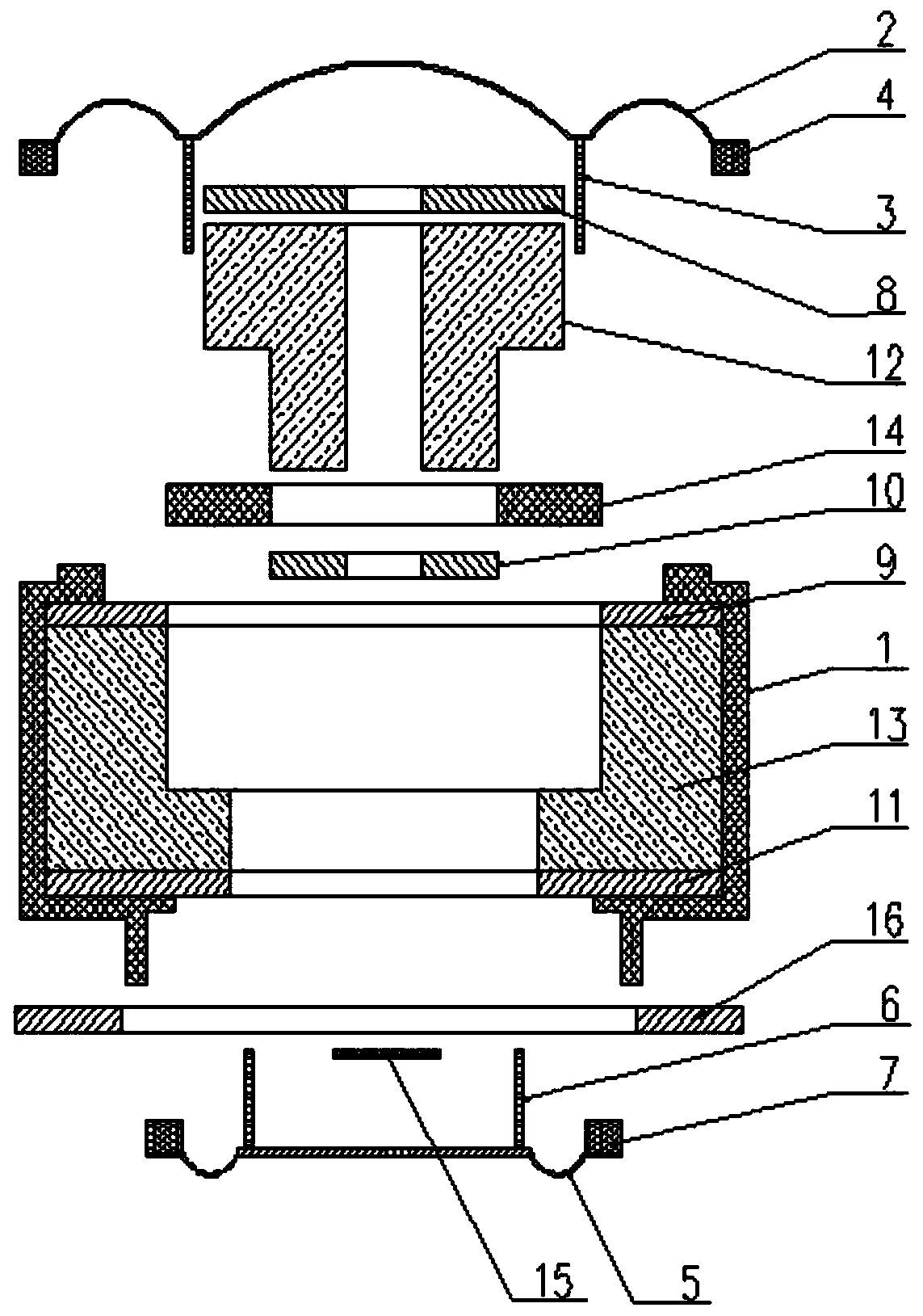

[0037] refer to Figure 1-2 , which shows the specific structure of the first preferred embodiment of the present invention, the specific implementation is: the first magnet 12 is provided with a first magnetically conductive plate 8, and the first magnet 12 is provided with a third magnetically conductive plate 8. Plate 10, the second magnet 13 is arranged on the outer periphery of the first magnet 12, is fixed with an annular connecting piece 14 between the first magnet 12 and the second magnet 13, is provided with the second magnetically conductive plate 9 above the second magnet 13, the second The second magnet 13 is provided with a fourth magnetically conductive plate 11, a first accommodating cavity 801 is formed between the outer circumference of the first magnetically conductive plate 12 and the inner circumference of the second magnetically conductive plate 13, and the third magnetically conductive plate 10 A second accommodating cavity 1001 is formed between the oute...

Embodiment 2

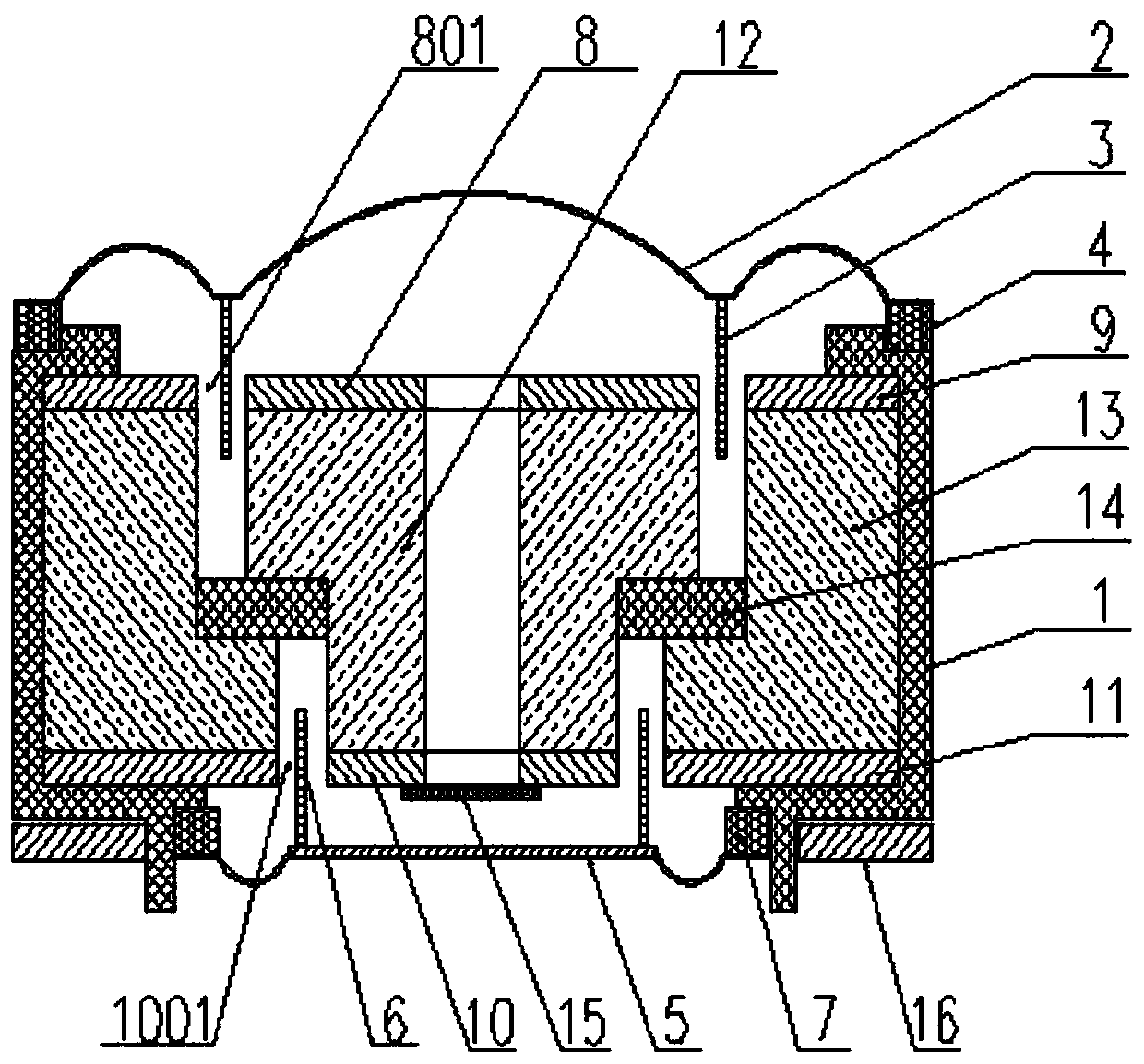

[0041] refer to image 3 , which shows the specific structure of the second preferred embodiment of the present invention, the specific implementation is: the first magnet 12 is provided with a first magnetically conductive plate 8, and the bottom of the first magnet 12 is provided with a third magnetically conductive Plate 10, the second magnet 13 is arranged on the outer periphery of the first magnet 12, is fixed with an annular connecting piece 14 between the first magnet 12 and the second magnet 13, is provided with the second magnetically conductive plate 9 above the second magnet 13, the second Below the second magnet 13 is provided with a fourth magnetically conductive plate 11, a first accommodating cavity 801 is formed between the outer circumference of the first magnetically conductive plate 8 and the inner circumference of the second magnetically conductive plate 9, and the third magnetically conductive plate 10 A second accommodating cavity 1001 is formed between t...

Embodiment 3

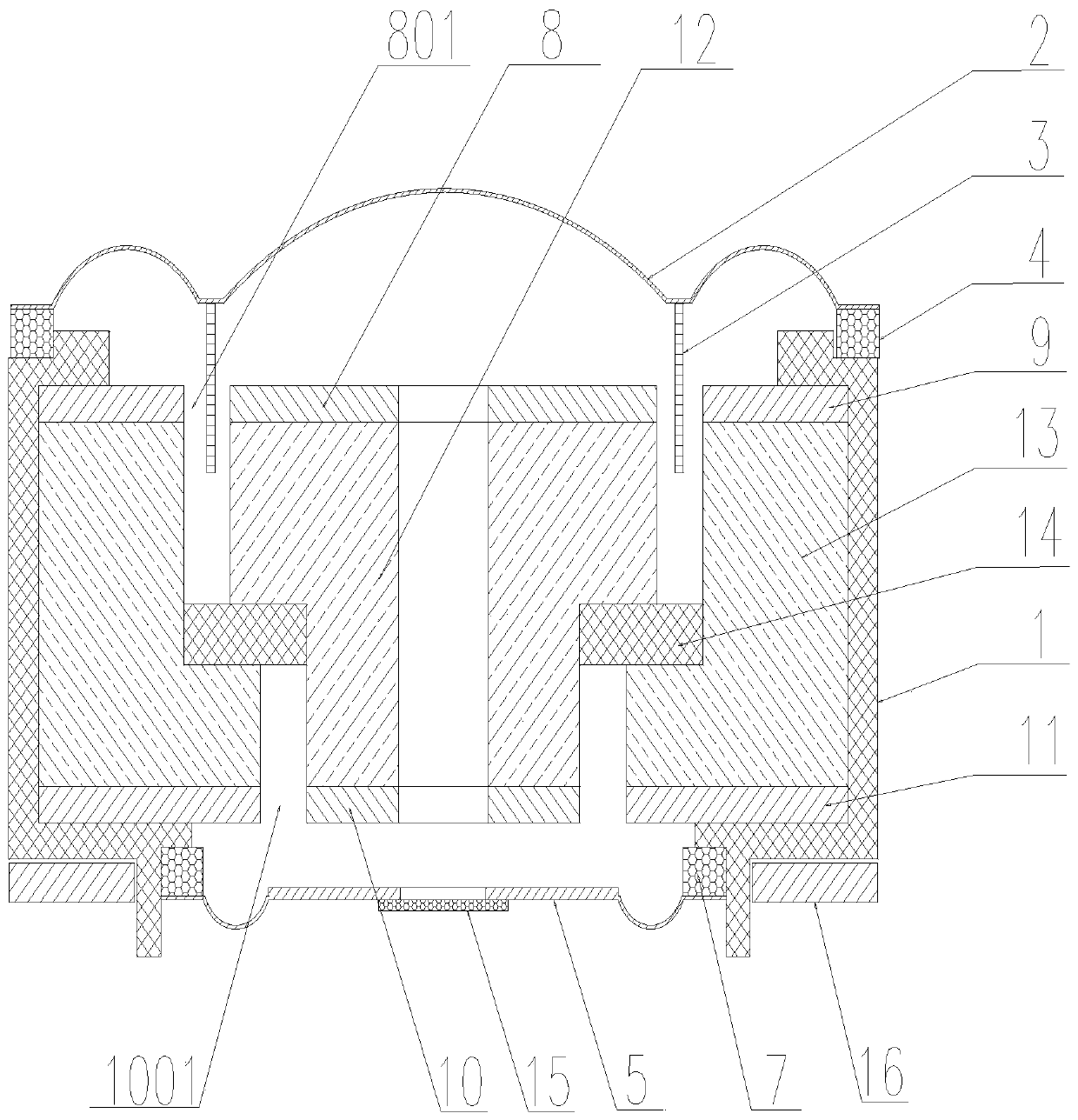

[0045] refer to Figure 4 , which shows the specific structure of the third preferred embodiment of the present invention, the specific implementation is: the first magnet 12 is provided with a first magnetically conductive plate 8, and the bottom of the first magnet 12 is provided with a third magnetically conductive Plate 10, the second magnet 13 is arranged on the outer periphery of the first magnet 12, is fixed with an annular connecting piece 14 between the first magnet 12 and the second magnet 13, is provided with the second magnetically conductive plate 9 above the second magnet 13, the second Below the second magnet 13 is provided with a fourth magnetically conductive plate 11, a first accommodating cavity 801 is formed between the outer circumference of the first magnetically conductive plate 8 and the inner circumference of the second magnetically conductive plate 9, and the third magnetically conductive plate 10 A second accommodating cavity 1001 is formed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com