Wide frequency response noise resistant adapterization probe adopting double piezoelectric ceramic wafers

A frequency response and ceramic chip technology, applied in the field of probes, can solve the problems of affecting the detection effect of ground vibration sound, sensitivity drop, detection sensitivity drop, etc., and achieve the effect of increasing the output frequency range, good effect, and wide frequency response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

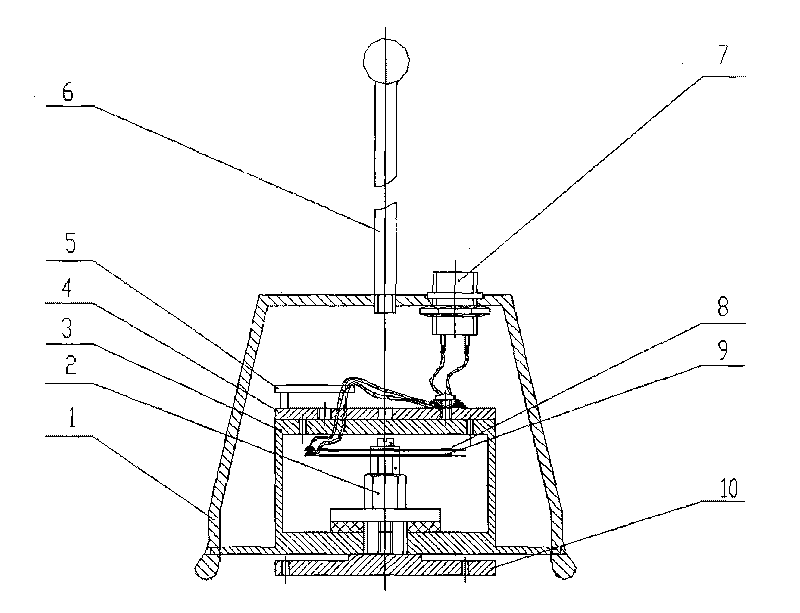

[0015] Describe an embodiment of the present invention below in conjunction with accompanying drawing.

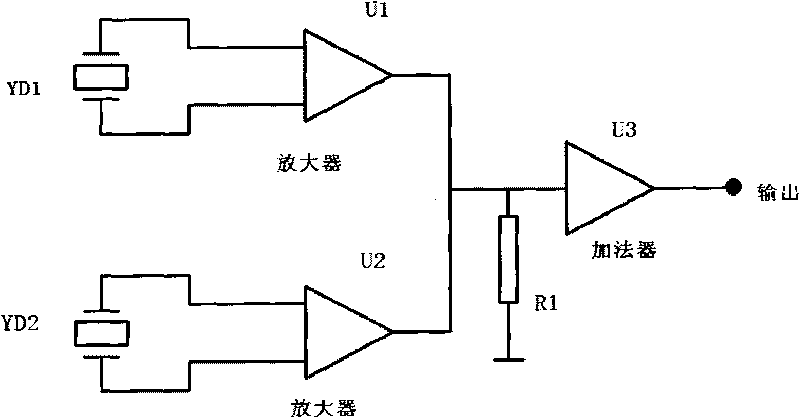

[0016] The circuit principle of this embodiment is as figure 1 Shown: Two piezoelectric ceramic sheets YD of different specifications are installed in one probe 1 , YD 2 , the natural frequency ω of the two piezoceramics n They are 700Hz and 1500Hz respectively, and their outputs are respectively connected to the circuit board. There are two independent impedance transformation amplifier circuits U on the circuit board. 1 , U 2 After completing the impedance transformation, it is connected to the adder U 3 , to complete the addition and output of the signal.

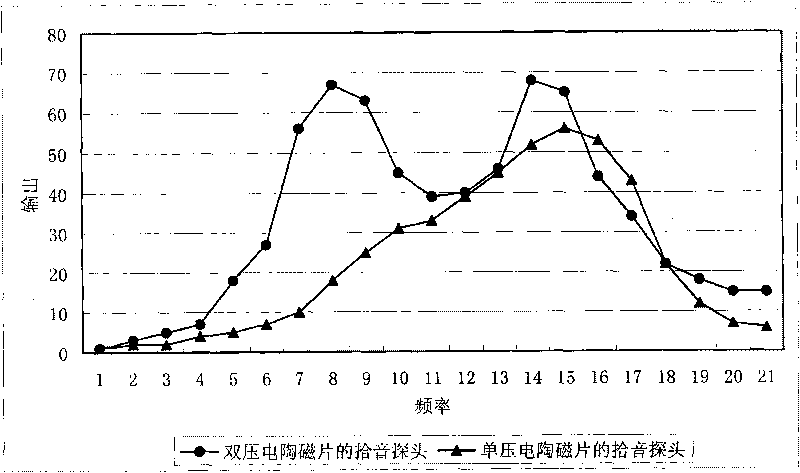

[0017] In this way, in different frequency intervals, the output of the piezoelectric ceramic sheet with higher sensitivity is larger, because the natural frequency ω of the two piezoelectric sheets n Different, the output frequency of the pick-up probe is extended after being added, such as figure 2 .shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com