Easy-to-clean fish farming equipment

A technology for fish breeding and equipment, applied in fish farming, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of low cleaning efficiency, inconvenient operation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

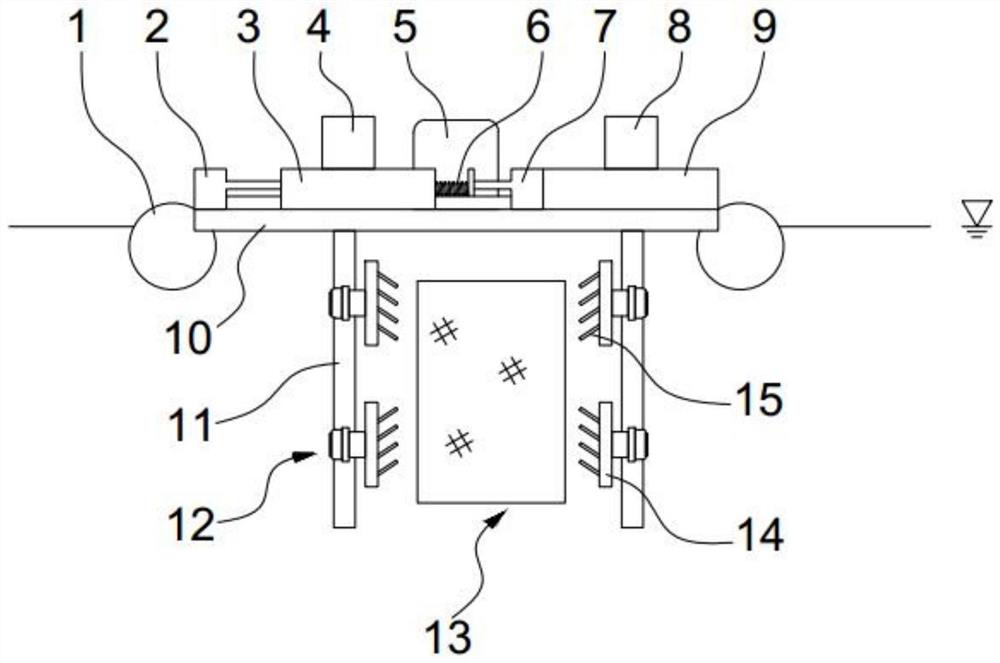

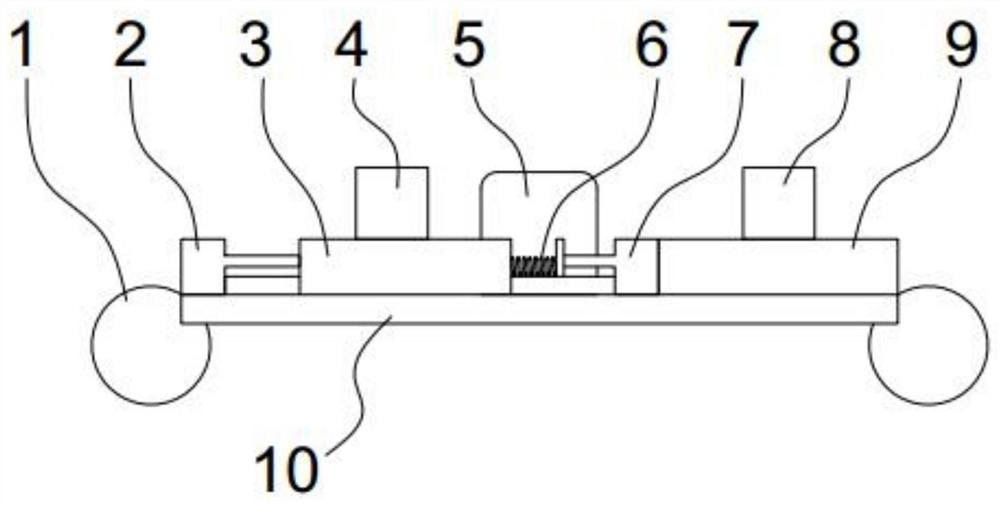

[0034] see Figure 1-5 Shown, easy-to-clean fish farming equipment, including:

[0035] The base part 10, the side of the base part 10 is connected with the floating body 1,

[0036] The slidable first sliding part 3 and the fixed second part 9 installed on the base part 10, the first sliding part 3 and the second part 9 are connected with the second hydraulic cylinder 7 through the elastic part 6,

[0037] Wherein the cleaning assembly 12 is respectively installed under the first sliding part 3 and the second part 9, and the first water pump 4 and the second suction pump 4 and the second pumping part 12 are respectively installed on the top of the first sliding part 3 and the second part 9 in cooperation with the corresponding cleaning assembly 12. water pump 8;

[0038]The present invention adopts the floating body 1 as a buoyancy support to suspend the base member 10 on the water surface, and uses the first sliding part 3 and the second part 9 to install the cleaning asse...

Embodiment 2

[0053] When the fish breeding equipment that is easy to clean of the present invention is actually used: the device of the present invention is placed above the net cage for marine culture, and the controller is used to control the power part 5 to float the base part 10 directly above the net cage 13 before cleaning, After contacting the net box 13 with the cleaning assembly 12 below the second part 9 as an anchor point, the controller controls the first hydraulic cylinder 2 to push the first sliding part 3 to slide until the cleaning assembly 12 below the first sliding part 3 is connected to the net. Box 13 touches, and the way of determining touch is to observe the power output data of the first hydraulic cylinder 2. Of course, in order to observe the touch more conveniently, an underwater camera can also be installed on the pipe body 11 of the cleaning assembly 12. After the touch is completed, Control the first hydraulic cylinder 2 to make the first sliding part 3 retract. ...

Embodiment 3

[0056] see Figure 6 As shown, this embodiment provides another implementation technical solution on the basis of embodiment 1. The difference between this embodiment and embodiment 1 is that the cleaning component in embodiment 1 is replaced by the second cleaning component 17, the first The second cleaning assembly 17 is made up of the spray plate 14 and the liquid outlet pipe 15 on its surface. The manner in which cleaning is performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com