Dry powder type fire extinguishing bag for bus

A technology of dry powder and public transportation, which is applied in fire rescue and other fields, and can solve the problems of limited number of fire extinguishers, inability to extinguish fires, threats to passenger safety, etc., and achieve the effects of automatic detection and judgment, low application cost, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

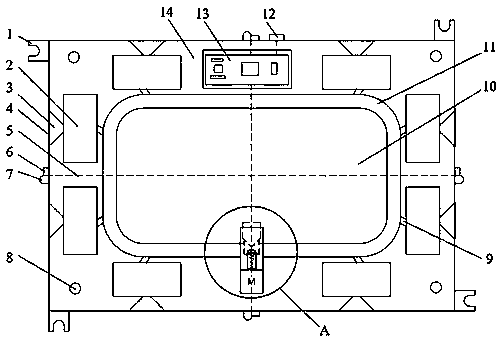

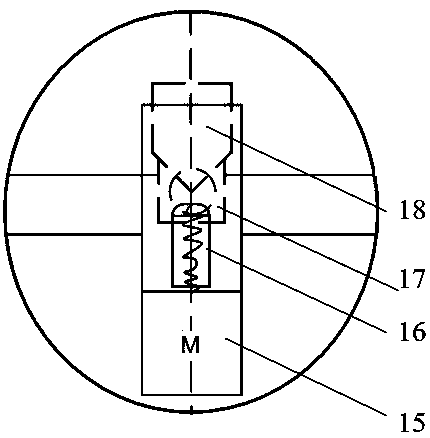

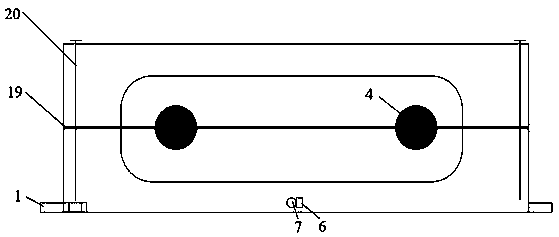

[0010] Provide specific embodiment of the present invention below and accompanying drawing illustrates:

[0011] figure 1 A high-pressure gas bag storage cavity 10 matching the high-pressure gas bag is dug in the middle of the cast aluminum base 14, and an annular groove 11 is dug around the high-pressure gas bag storage cavity 10, and the annular groove 11 is connected with the dry powder tank 2 through the chute 9 , the dry powder tank 2 is connected with the trumpet-shaped spout 3, and the trumpet-shaped spout 3 is covered with a layer of plastic film 4. The dry powder tank adopts a deep cubic structure and is mainly used to store dry powder for fire extinguishing. The fire extinguishing bag is installed in the bus with the mounting ear 1. The smoke sensor 6 and the flame sensor 7 are connected to the main control board 13 through the signal line 5, and the main control board 13 is connected to the motor 14 through the motor connection line. The wire and the main control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com