Landfill leachate biochemical effluent treatment reactor and method

A technology of landfill leachate and biochemical effluent, applied in chemical instruments and methods, polluted groundwater/leachate treatment, water/sewage treatment, etc., can solve the problem that COD and TN cannot be removed at the same time, and achieve the effect of relieving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

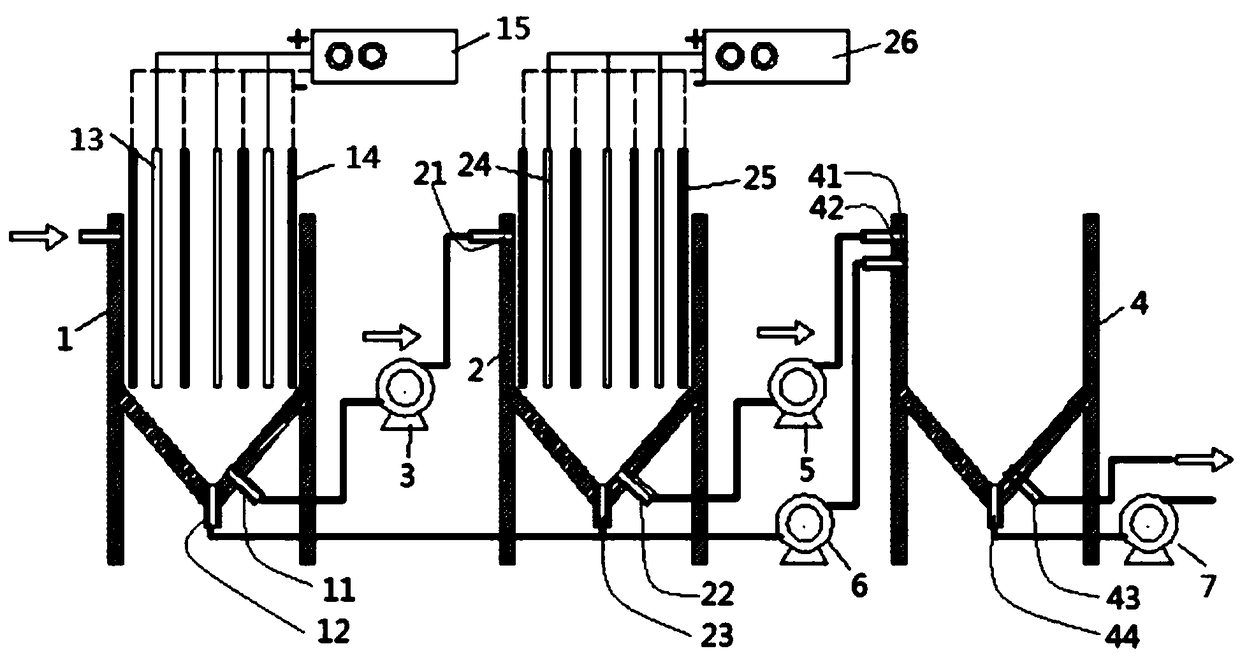

[0076] Such as figure 1 As shown, a landfill leachate biochemical effluent treatment reactor includes: an electrochemical flocculation device 1 , wherein four first cathode plates 14 and three iron anode plates 13 are arranged crosswise in the electrochemical flocculation device 1 . During the operation of the electrochemical flocculation device 1 , the first DC power supply 15 is used for power supply. After the electrochemical flocculation reaction and precipitation, the third pump 6 is turned on to transfer the reducing sludge to the available chlorine elimination device 4 . After the transfer of the reducing sludge is completed, the third pump 6 is turned off, the first pump 3 is turned on, and the electrochemical flocculation effluent is transferred to the electrochemical oxidation device 2 . In the electrochemical oxidation device 2, the second DC power supply 26 is used for power supply. After the electrochemical oxidation reaction precipitation is completed, the second...

Embodiment 2

[0079] The treatment reactor is set up as in Example 1, and the actual landfill leachate biochemical effluent is used as the experimental object, and the current density is set to 50mA / cm during the reaction process 2 , the reaction time in the electrochemical flocculation device 1 is 60min, the reaction time in the electrochemical oxidation device 2 is 120min, the reaction time in the available chlorine elimination device 4 is 10min, and the third solution effluent 43 of the available chlorine elimination device 4 flows out after the reaction BOD in solution 5 The / COD value rose to 0.35 compared to 0.065 of the influent, indicating that the effluent was suitable for further treatment by the microbial reactor. Among them, the COD that can be used by microorganisms is BOD. This is usually the 5-day biochemical oxygen demand, denoted as BOD 5 . BOD 5 / COD is also BOD 5 The proportion in the total COD. The influent is the biochemical aqueous solution entering the electroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com