C-column reinforcing plate connecting structure

A technology of connecting structures and reinforcing plates, applied in the field of auto parts, can solve the problems of local stress concentration of the body, unclear transmission path, poor passenger experience, etc., and achieve the effect of preventing local stress concentration, avoiding body cracking, and improving torsional stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

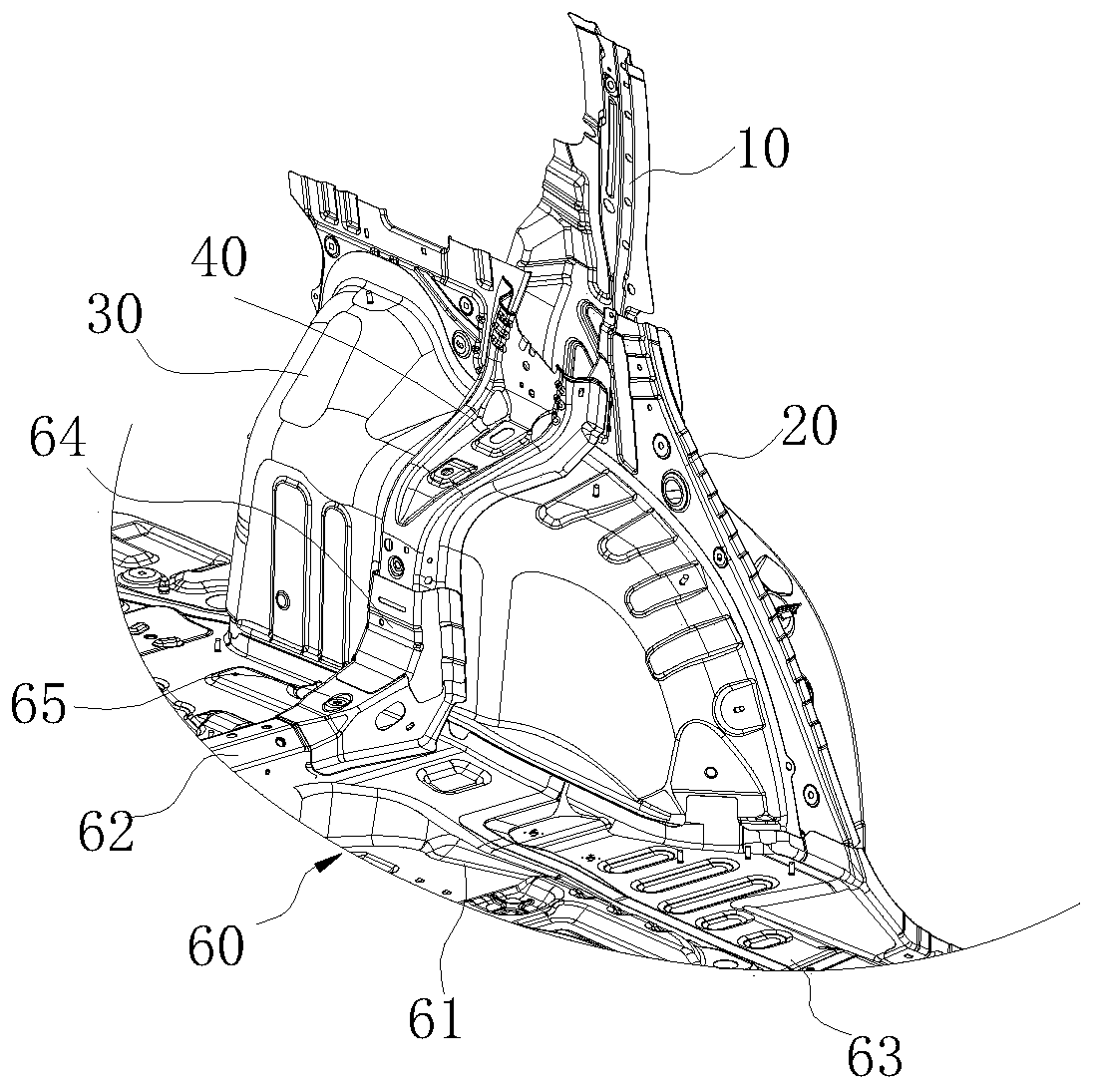

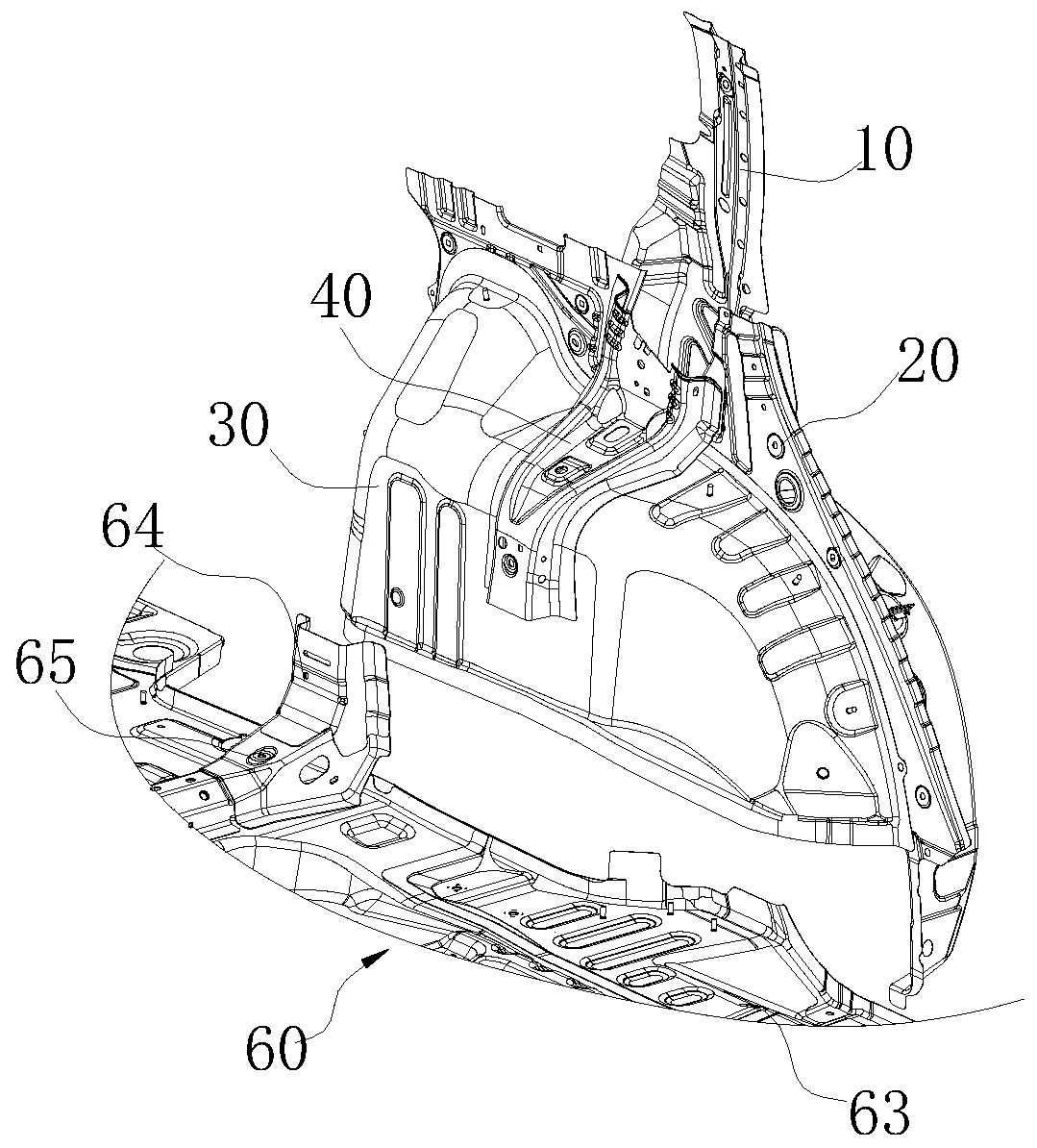

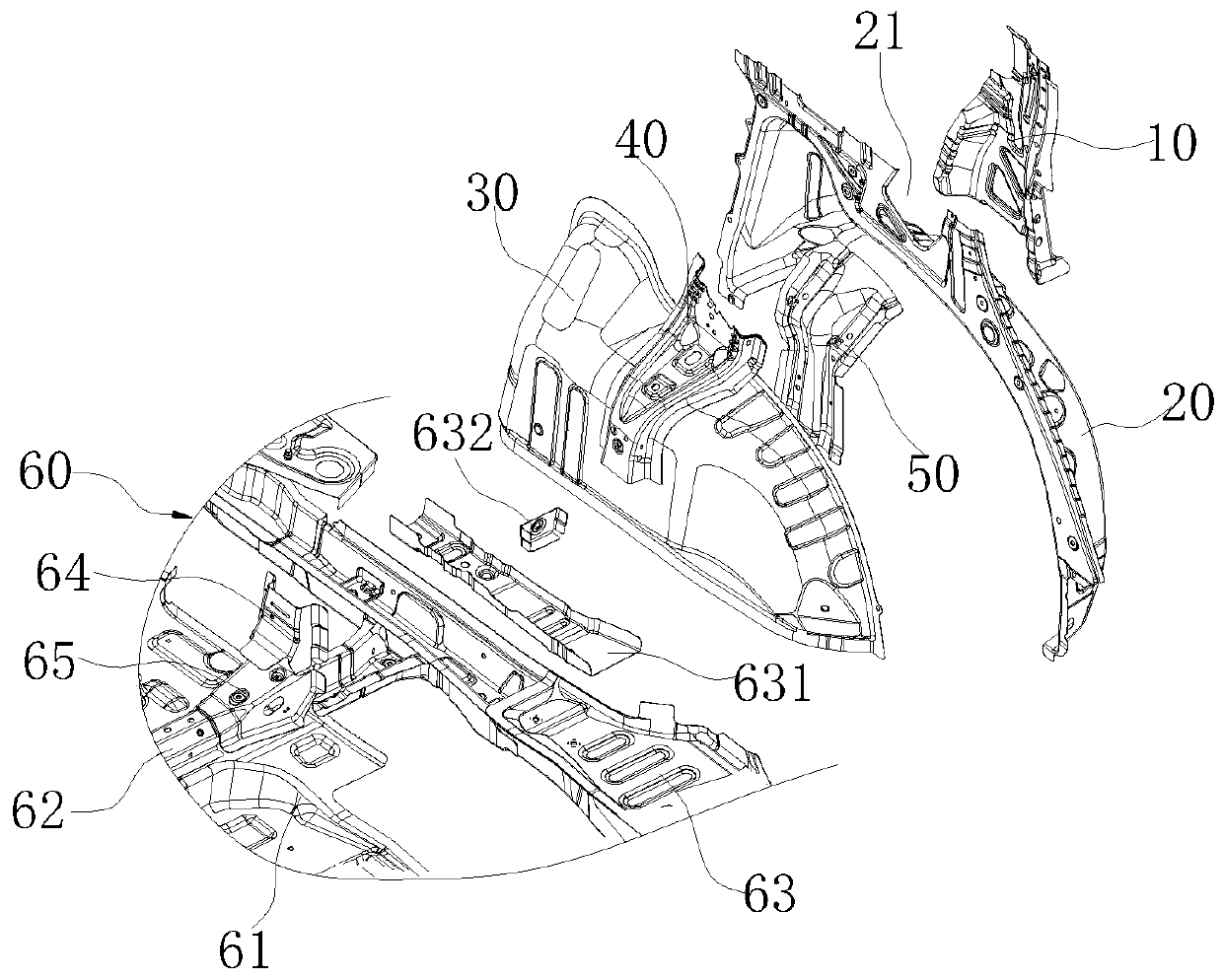

[0008] refer to Figure 1-Figure 3 , a C-pillar reinforcement plate connection structure, comprising a C-pillar reinforcement plate 10, the upper end of the C-pillar reinforcement plate 10 extends to the side beam of the vehicle body, the lower end is welded to the outer side of the rear wheel house outer panel 20, and the rear wheel house outer panel 20 is connected to the rear wheel house outer panel 20. Wheelhouse inner panel 30 is welded as a whole, and the inboard of rear wheelhouse inner panel 30 is provided with rear wheelhouse inner panel stiffener 40, and the upper end of rear wheelhouse inner panel stiffener 40 protrudes to the top of rear wheelhouse inner panel 30 and It is welded with the rear wheel house outer panel 20, and the described C-pillar reinforcing plate 10 and the rear wheel house inner panel reinforcing plate 40 are welded as one. The upper end of the C-pillar reinforcement plate 10 is connected to the side beam of the vehicle body, and the lower end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com