Universal check bolt and assembly and installation method thereof

An anti-loosening bolt and anti-loosening technology, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of inability to disassemble bolts, inconvenient disassembly, troublesome construction, etc., to facilitate later disassembly and maintenance, avoid locking bolts, and naturally facilitate assembly and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

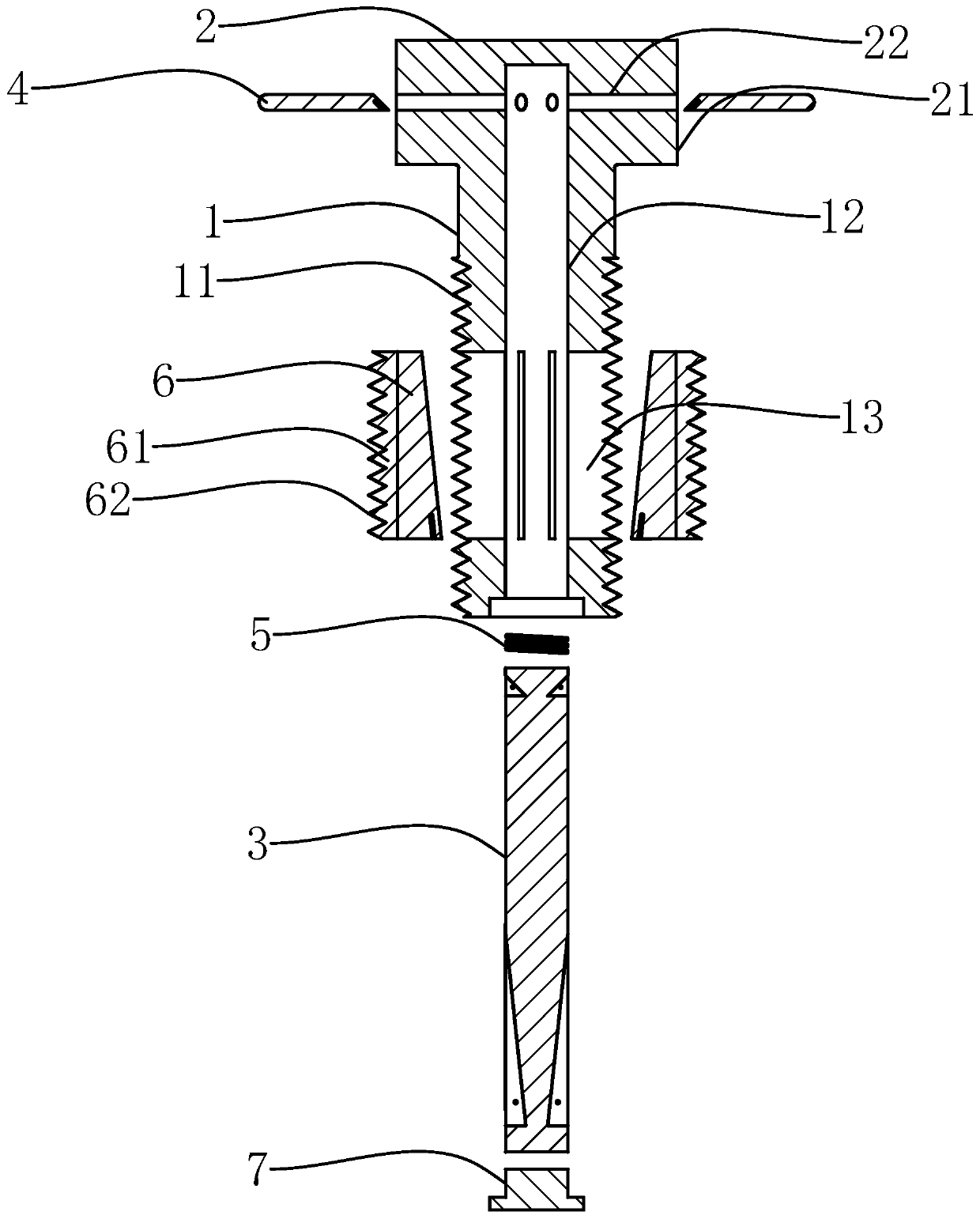

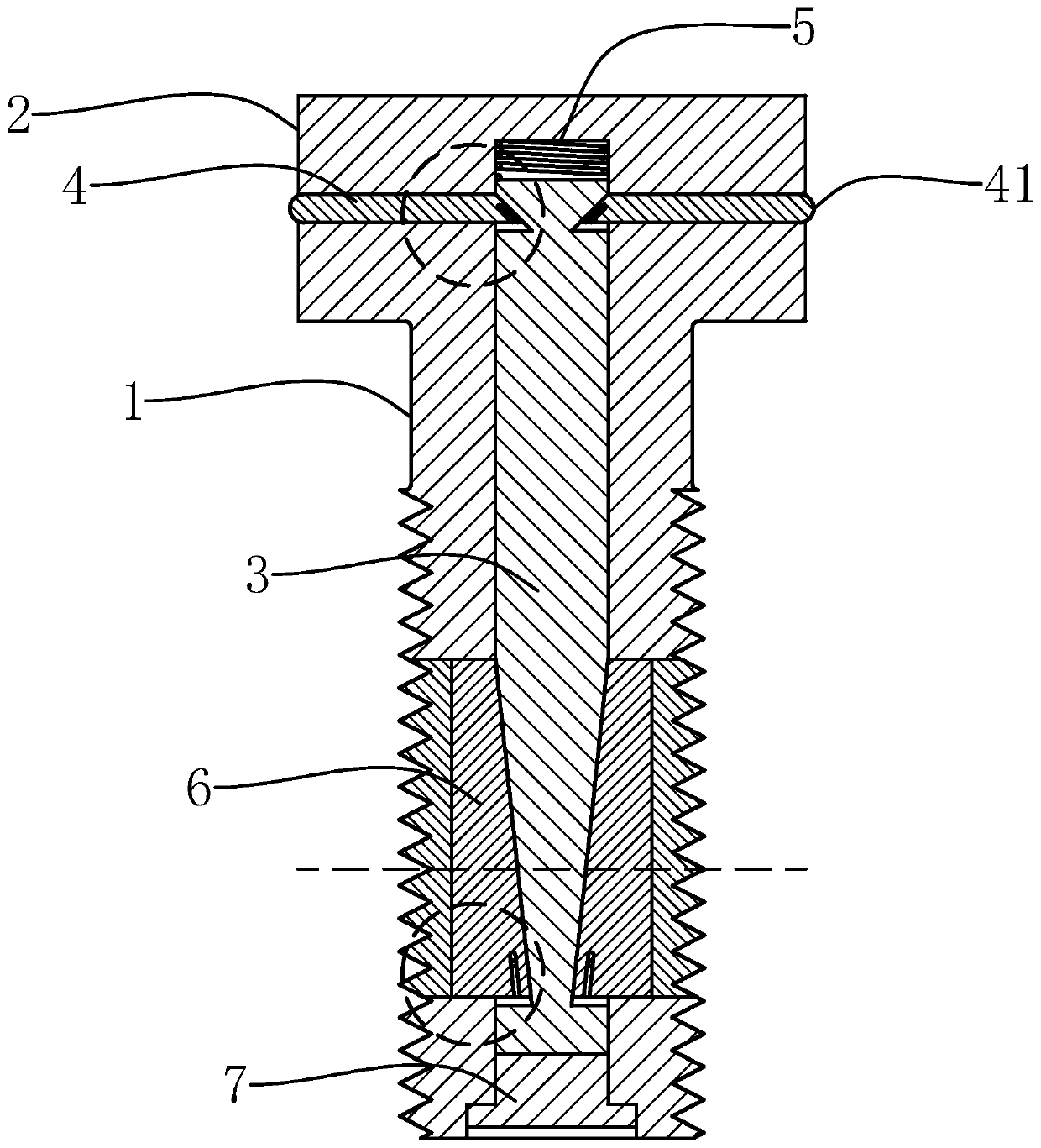

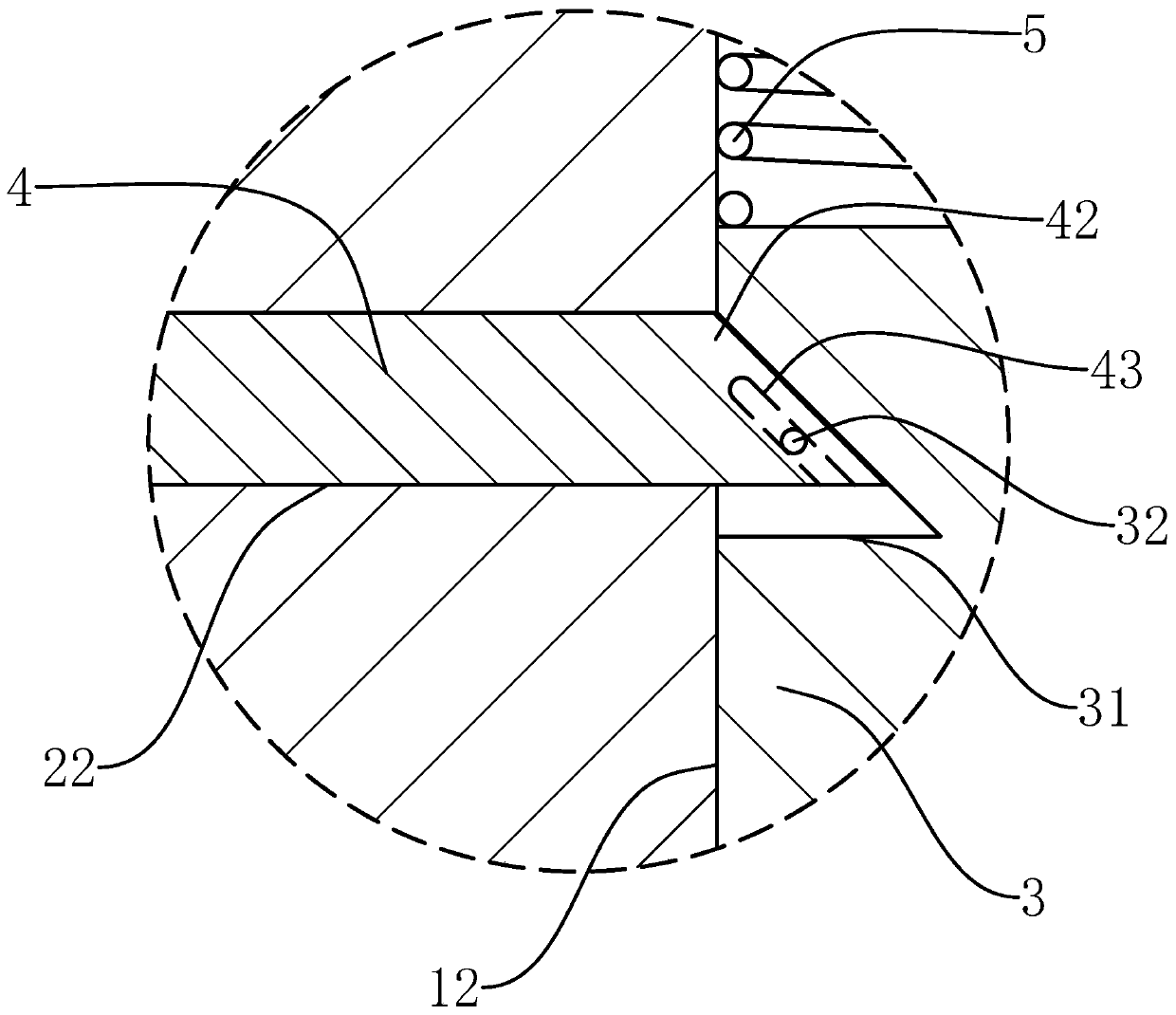

[0052] Such as Figure 1-9 As shown, a general anti-loosening bolt of the present invention includes a screw rod 1 and a bolt head 2 connected to the top of the screw rod 1. The outer circumference of the screw rod 1 is provided with a thread 11, and the screw rod 1 is provided with a movable chamber 12, and the movable chamber 12 is equipped with a There is a rod-shaped movable rod 3 coaxial with the screw 1, and the top of the movable chamber 12 extends toward the bolt head 2. The screw 1 is provided with a number of anti-loosening holes 13 of sheet structure, and several anti-loosening holes 13 are distributed along the circumferential direction of the screw 1. The length direction of the anti-loosening hole 13 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com