Cooler and refrigerant detection method, device and system thereof

A refrigerant detection and detection device technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as poor reliability, and achieve the effect of avoiding damage and strong detection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of this application, the following will make a more comprehensive description of this application with reference to the relevant drawings. The drawings show preferred embodiments of the application. However, this application can be implemented in many different forms and is not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the understanding of the disclosure of this application more thorough and comprehensive.

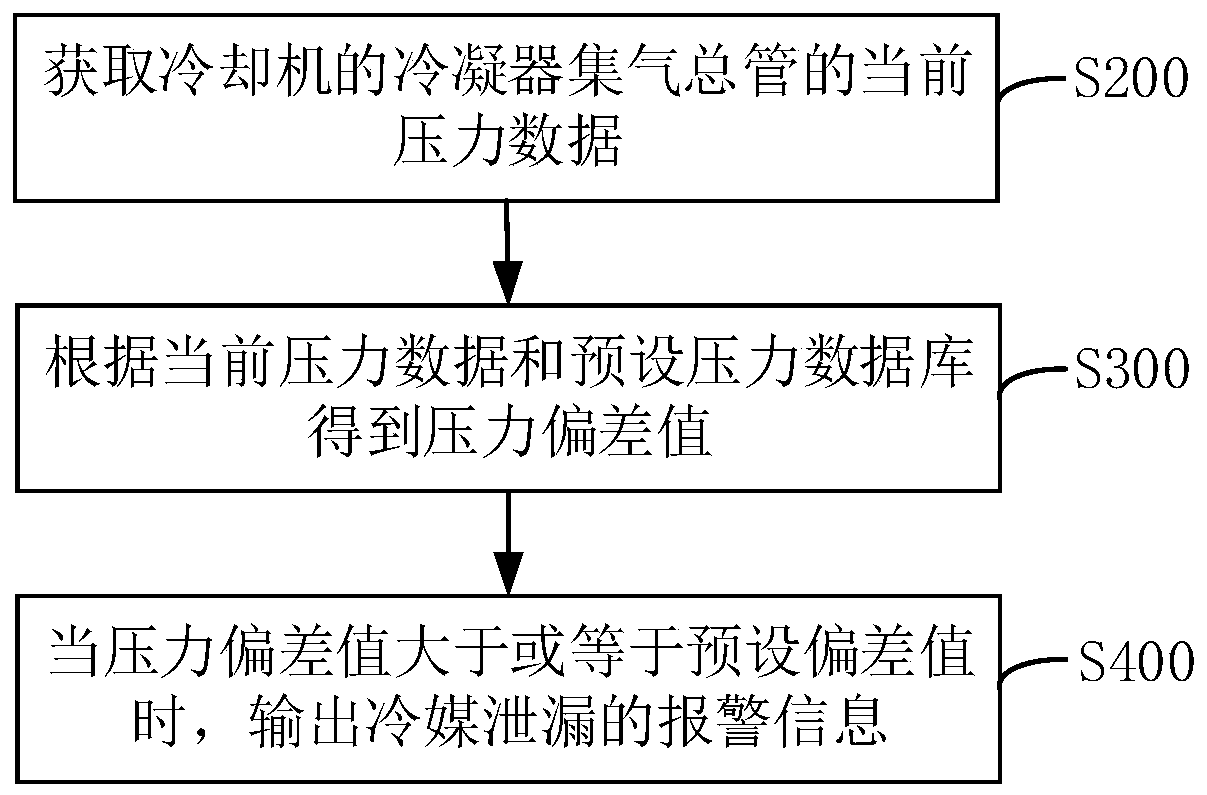

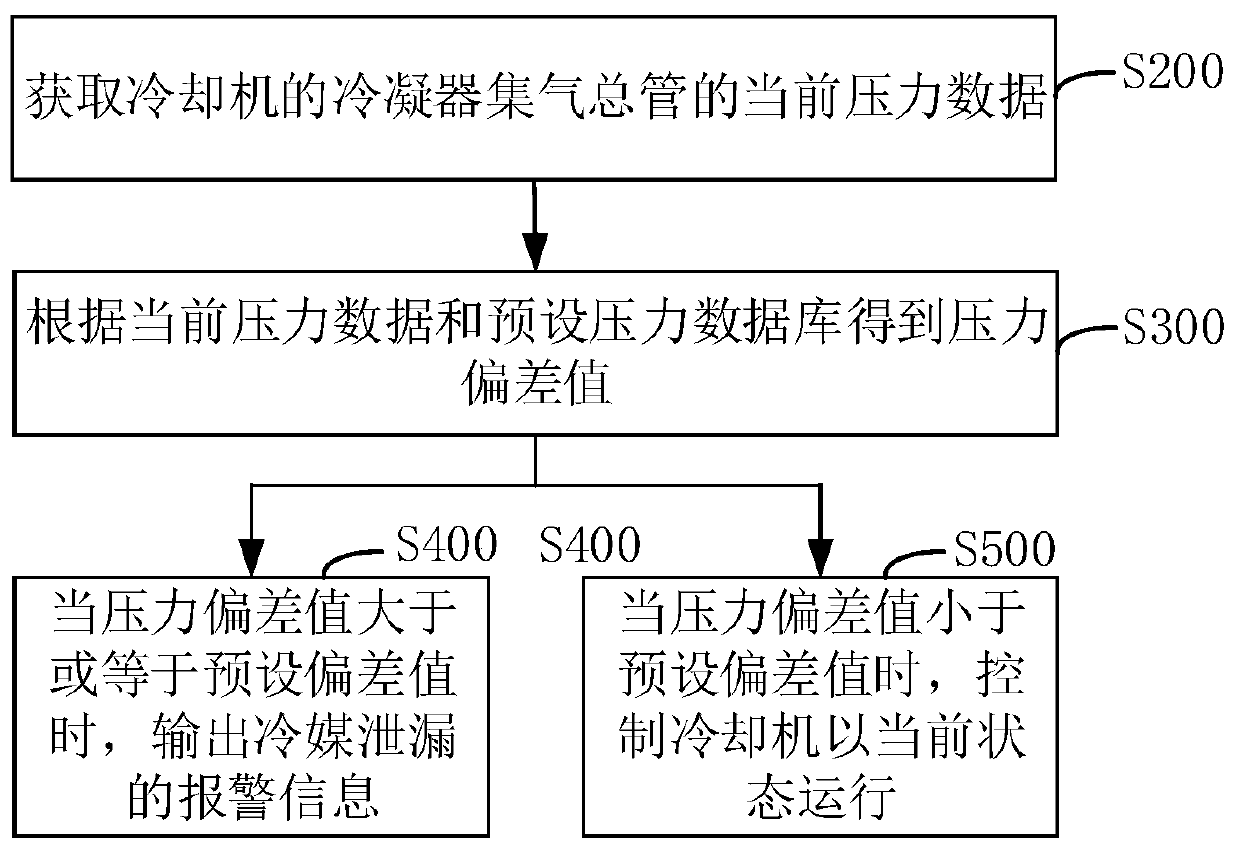

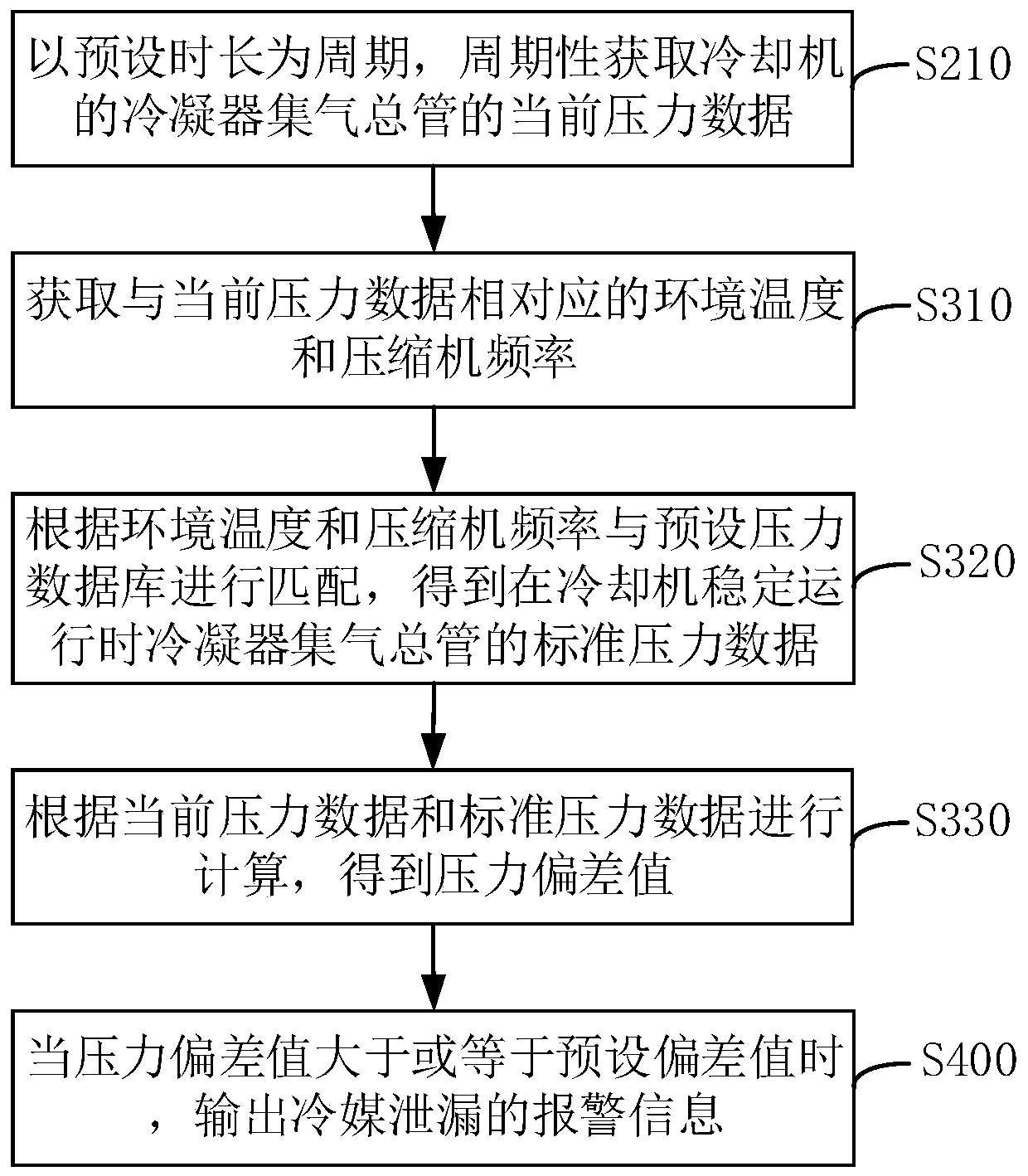

[0028] See figure 1 , A refrigerant detection method for a cooling machine, including: step S200, step S300, and step S400.

[0029] Step S200: Obtain the current pressure data of the condenser gas header of the cooling machine.

[0030] Specifically, the condenser is a kind of heat exchanger, which can convert gas or vapor into liquid, and transfer the heat in the tube to the air near the tube in a fast manner. The working process of the condenser is an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com