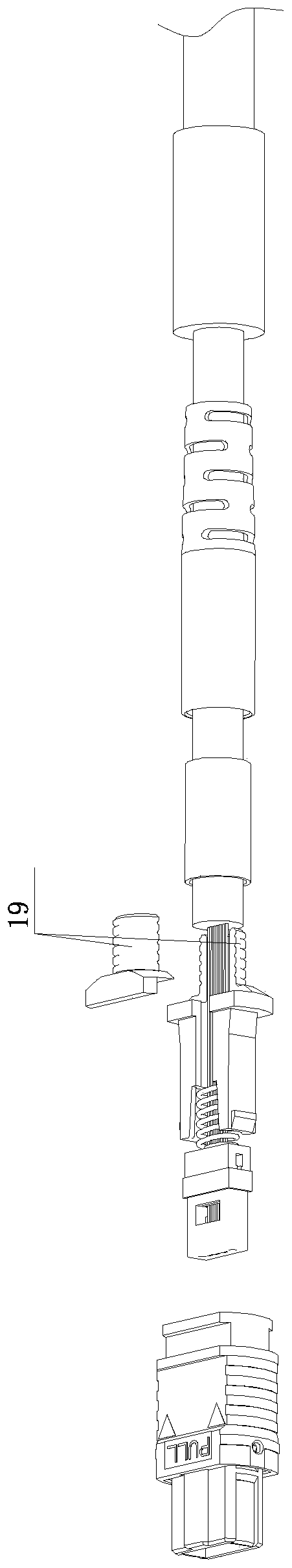

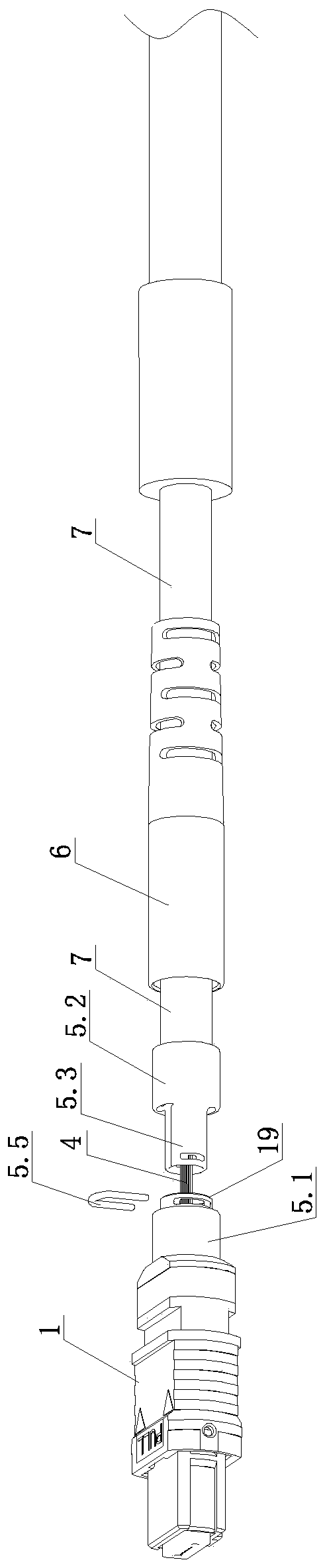

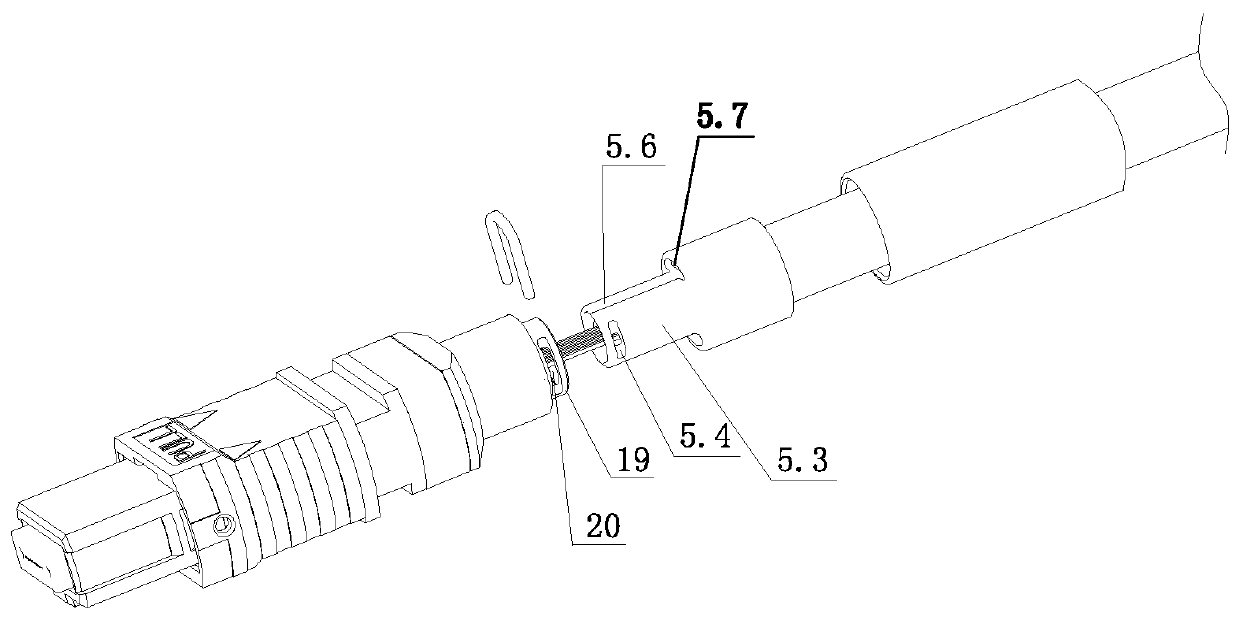

Split-type crimping MPO (Maximum Power Output) plug

A plug and split technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of rework and grinding work, easy to break and fail, fiber scrapping and other problems, so as to improve maintenance efficiency and quality, and facilitate rework, grinding and repair work convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further illustrate the technical means and technical effects adopted by the present invention, a split crimping MPO plug of the present invention will be described in detail below in conjunction with the embodiments.

[0043] The MPO plug mainly includes the outer shell 1, the pin part 2, the spring 3, the limit seat, the crimping sleeve 5 and the tail sheath 6. For the convenience of explanation, the end where the pin part is located is defined as the front end. Figure 1-Figure 3 and Figure 5-Figure 9 All are shown with the left end as the front end. In the prior art, the limit seat and the spring in the MPO plug are set on the optical fiber 4 at the front end of the optical cable 7, the spring is wrapped in the limit seat, the front end of the optical fiber is connected to the pin part, and the spring and the limit seat are both set on the pin After the rear end of the component and the limit seat are installed, arrange the tensile element (the tensile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com