A tea picking machine and a tea picking method using the tea picking machine

A technology for tea picking machines and tea leaves, which is applied to picking machines, agricultural machinery and tools, and applications. It can solve problems such as broken fracture sections and uneven fracture surfaces of tea leaves, so as to achieve the effect of ensuring the beauty and taste of tea soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

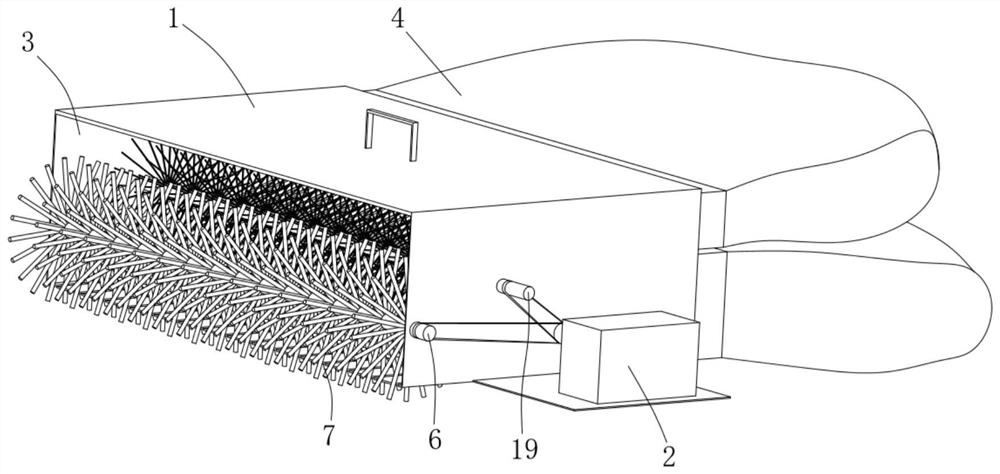

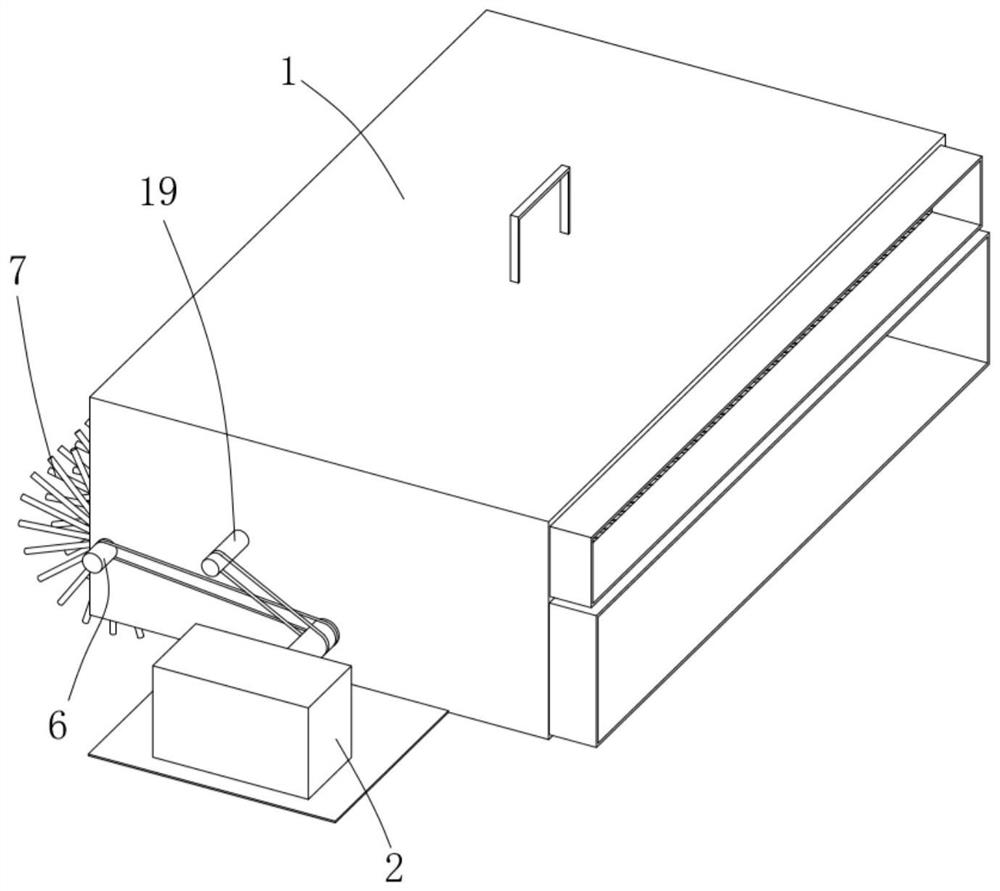

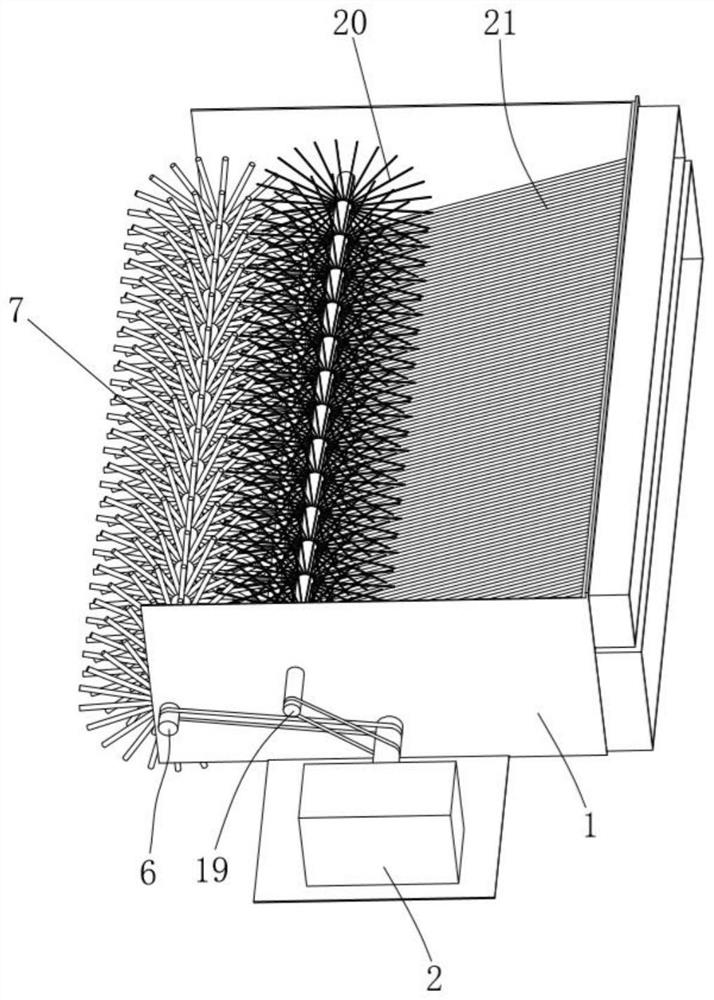

[0072] Example 1, such as Figure 1-5 Shown:

[0073] A tea picking machine, comprising a collection box 1, a picking assembly arranged in the collection box 1, and a driving part 2 for driving the picking assembly. In this embodiment, the driving part 2 adopts a conventional small motor , is arranged outside the collection box 1, and is fixedly connected with the collection box 1. The motor is powered by a battery, which is convenient to move in the tea garden. One end of the collection box 1 along the horizontal direction is the entry end 3 for fresh tea leaves to enter. The inlet end 3 is open, and a collection assembly 4 is also arranged on the collection box 1, and the collection assembly 4 is used to collect the picked tea leaves in the collection box 1,

[0074] The picking assembly includes an extruding part 5 and a first rotary shaft 6, the extruding part 5 and the bottom plate 9 of the collection box 1 are in clearance fit, and the driving part 2 drives the first ro...

Embodiment 2

[0113] Example 2, such as Figure 1-9 said,

[0114] A method for picking tea leaves, comprising the steps in turn:

[0115] One, initial picking, adopt above-mentioned tea picking machine to gather the leaf bud on the tea tree treetop;

[0116] Two, Jingcai, artificially collect the leaf buds on the tea tree treetops after the collection in step one;

[0117] Three, machine mining, adopt the shear type tea picking machine to collect the tea tree tree tops after step 2 collection.

[0118] The tea picking method of this embodiment is especially suitable for the graded picking of tea leaves. In step 1, the tea picking machine mentioned above in this embodiment is used to collect the leaf buds. Adjustment of high-quality tea leaves such as one bud with one leaf, one bud with two leaves, and one bud with three leaves. Picking again by manual picking, because a large part of the collection is completed in step 1, so the collection of step 2 is more convenient and quick, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com