Spraying dust removal equipment with wind direction track changing technology

A kind of dust removal equipment and technology, applied in the direction of dispersion particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of unsatisfactory gas dust concentration, limit the practicability of processing equipment, increase power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

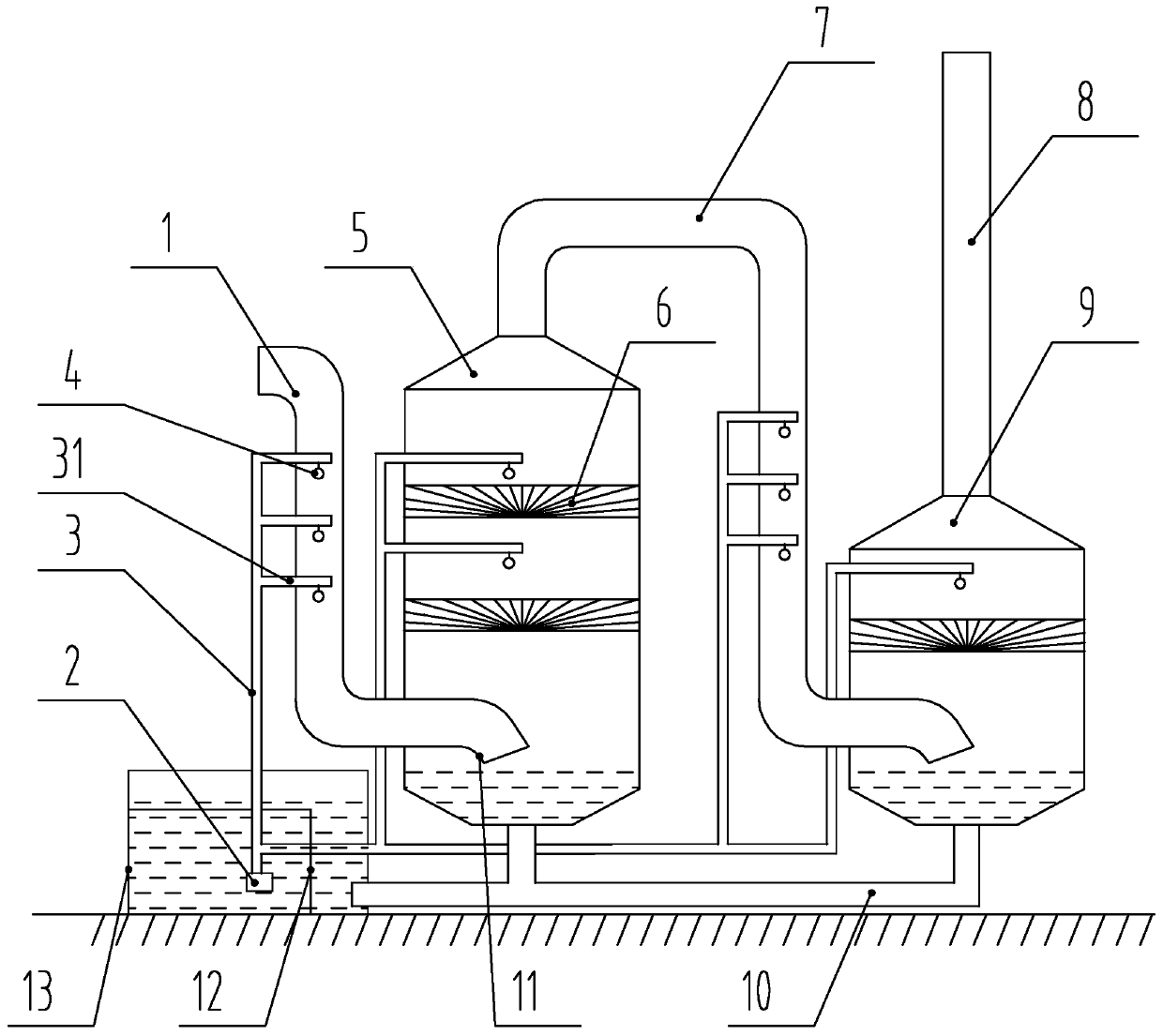

[0015] Combine below figure 1 The technical solution of the present invention will be described in further detail, but not limited to this description.

[0016] A spray dedusting equipment with wind direction changing technology includes air inlet pipe, water inlet pipe 3, spray head 4, spray tower, exhaust pipe 8, recovery water tank 13, water pump 2; described air inlet pipe and spray tower The bottom is fixedly connected, the sprinkler head 4 is connected to the water inlet pipe 3, the water pump 2 is arranged between the water inlet pipe 3 and the recovery water tank 13, and the water pump 2 can send water to the sprinkler head 4, so The exhaust pipe 8 described above is arranged on the top of the spray tower, and the dust gas enters the spray tower and is discharged through the exhaust pipe 8 after being filtered; One end of the water branch pipe 31 is connected with the water inlet pipe 3, and the other end penetrates into the air inlet pipe. The spray head 4 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com