Process and equipment for flue gas roasting, adsorption desulfurization, dust removal and purification by adopting combination process

An adsorption desulfurization and purification process technology, applied in the field of roasting flue gas purification, can solve the problems of low adsorption and reaction capacity, nitrogen oxides and sulfide pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

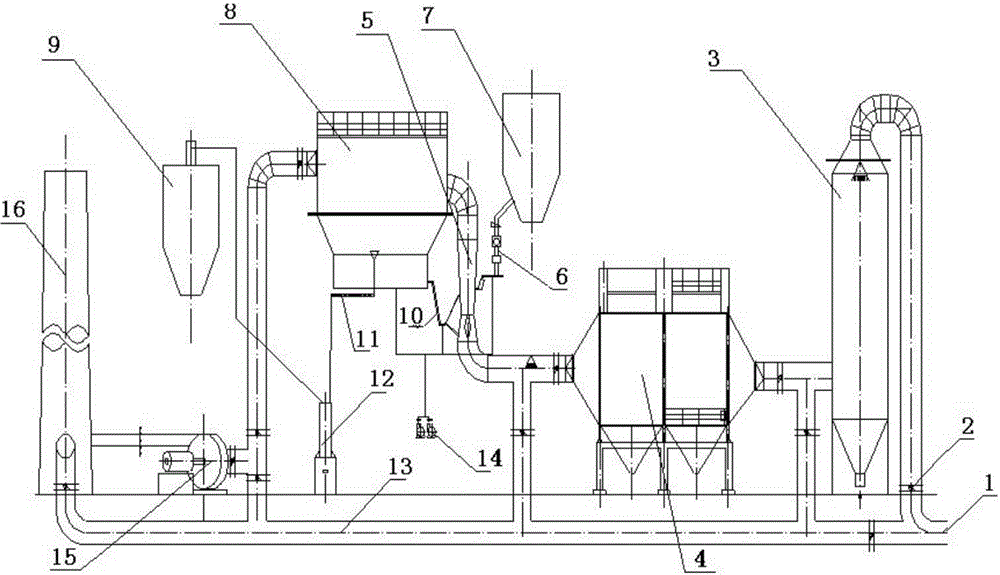

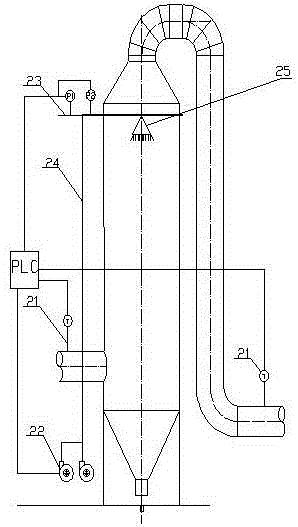

[0062] as attached figure 1 As shown, the combined roasting flue gas adsorption desulfurization and dust removal purification process, its device is mainly composed of spray tower 3, electric tar catcher 4, adsorption reactor 5, bag filter 8, induced draft fan 15, flue gas pipeline, silo, etc. Composition, the flue gas pipe of the roaster flue gas leads into the spray tower 3, the tower body is provided with a spray device at the lower part of the inlet flue gas pipe, the spray device is connected to the high-pressure air pipelines of the water pump 22, and the tower body is provided with an evaporation and condensation section.

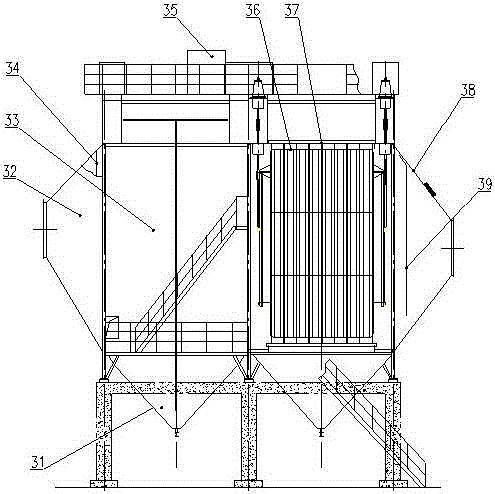

[0063] The outlet pipe of the spray tower 3 is connected to the inlet of the electric tar catcher 4. The electric tar catcher 4 is provided with a shell, and the two ends of the shell are respectively provided with a flue gas air inlet 32 and an air outlet 38. The air inlet 32 is provided with a multi-layer The flue gas flow uniform distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com