Comprehensive adsorption and desulphurization dedusting purification method of baking flue gas

A technology for adsorption desulfurization and flue gas, which is applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve environmental hazards and other problems, and achieve the effects of less investment, high degree of automation control, and excellent flue gas emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

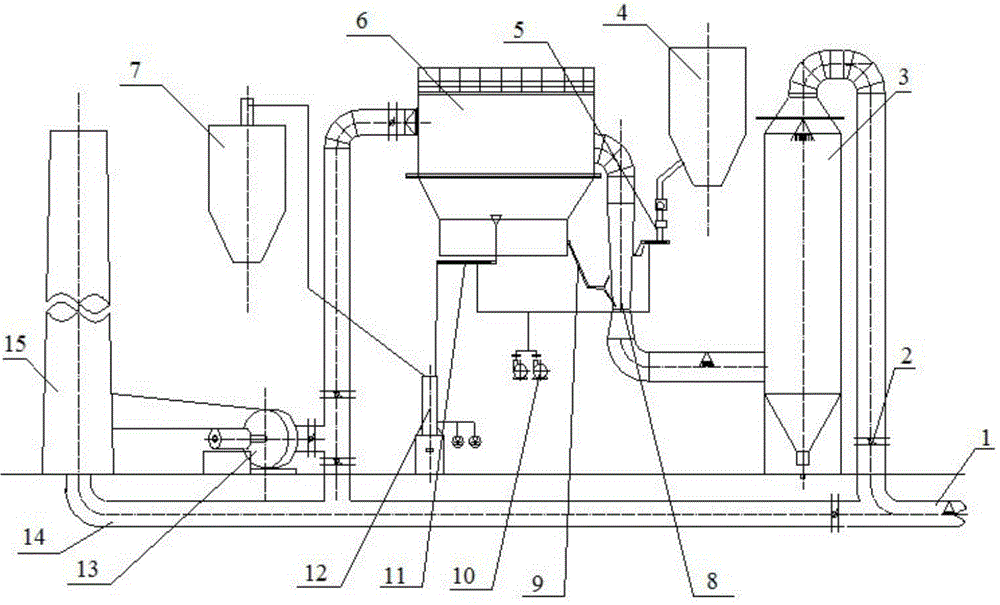

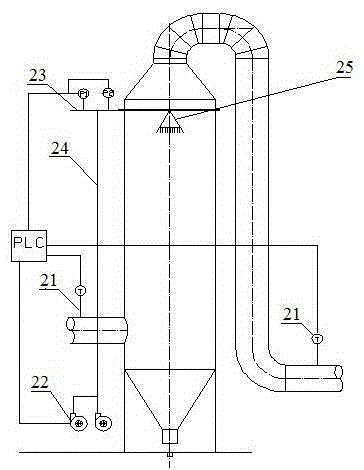

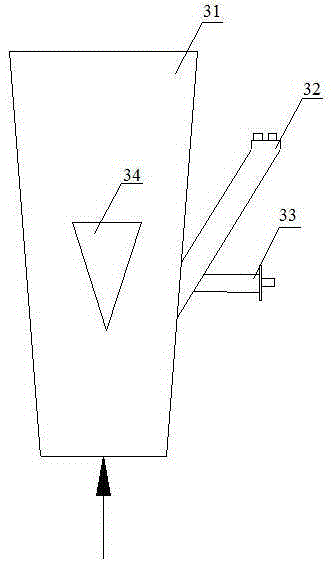

[0048] As attached figure 1 As shown, the roasting flue gas integrated adsorption desulfurization and dust-removing purification process of this patent uses 13 induced draft fan suction to make the roasting furnace flue gas enter the spray tower 3 for cooling and cooling, and the cooled flue gas enters the adsorption reactor 8 and calcium hydroxide The powder is fully mixed and adsorbs the harmful substances, and then enters the bag filter 6 to separate the gas-solid mixture, discharges clean gas, and separates the calcium hydroxide that has adsorbed harmful substances from the calcium hydroxide. The calcium hydroxide is recycled through 9 cycles. The calcium hydroxide conveying device is recycled and reused. The calcium hydroxide containing adsorbent is collected and transported to the pneumatic elevator 12 through the 11-cycle calcium hydroxide conveying device, and the material is conveyed by the gas to the calcium hydroxide material warehouse 7 as a calcined desulfurizer. Or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com