Special repair screw tap for spark plug

A technology of spark plugs and taps, which is applied in the field of special repair taps for spark plugs, can solve the problems of low precision, slow cutting speed of taps, and affecting the personal safety of operators, so as to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

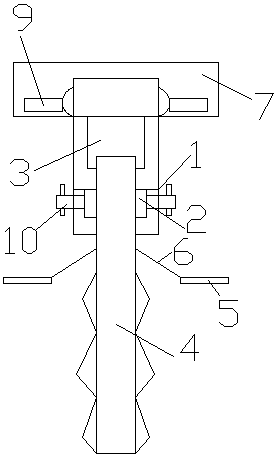

[0013] The spark plug special repair tap is provided with an upper handle 1, an engaging device 2 is arranged on the inside of the upper handle 1, a telescopic rod 3 is arranged in the engaging device 2, and a tap head 4 is arranged on the lower side of the telescopic rod 3. Both sides of the tap head 4 are provided with shields 5, the shield 5 and the tap head 4 are connected by a movable rod 6, and the movable rod 6 is movably inserted into the tap head 4, and the two sides of the upper handle 1 are provided with Protective circle7.

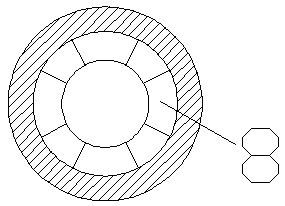

[0014] The said occlusal device 2 is a occlusal ring, and occlusal teeth 8 are arranged in the occlusal ring.

[0015] The occlusal teeth 8 are arranged around the inner wall of the occlusal ring, and the occlusal teeth 8 are pointed or arc-shaped.

[0016] The shield 5 is a transparent rubber shield, and the shield 5 and the movable rod 6 are connected to each other.

Embodiment 2

[0018] The spark plug special repair tap is provided with an upper handle 1, an engaging device 2 is arranged on the inside of the upper handle 1, a telescopic rod 3 is arranged in the engaging device 2, and a tap head 4 is arranged on the lower side of the telescopic rod 3. Both sides of the tap head 4 are provided with shields 5, the shield 5 and the tap head 4 are connected by a movable rod 6, and the movable rod 6 is movably inserted into the tap head 4, and the two sides of the upper handle 1 are provided with Protective circle7.

[0019] The said occlusal device 2 is a occlusal ring, and occlusal teeth 8 are arranged in the occlusal ring.

[0020] The occlusal teeth 8 are arranged around the inner wall of the occlusal ring, and the occlusal teeth 8 are pointed or arc-shaped.

[0021] The shield 5 is a transparent rubber shield, and the shield 5 and the movable rod 6 are connected to each other.

[0022] The protection ring 7 is a rubber ring, and an adsorption block 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com