Disk part oblique plane point depth measuring method and device

A technology of depth measurement and parts, which is applied in the field of depth measurement of points on the web slope of thin-walled disk parts during machine tool processing, which can solve the problem of parts clamping deformation, prolonging the production cycle of parts, and the inability to detect parts on machine tools Problems such as point depth on slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

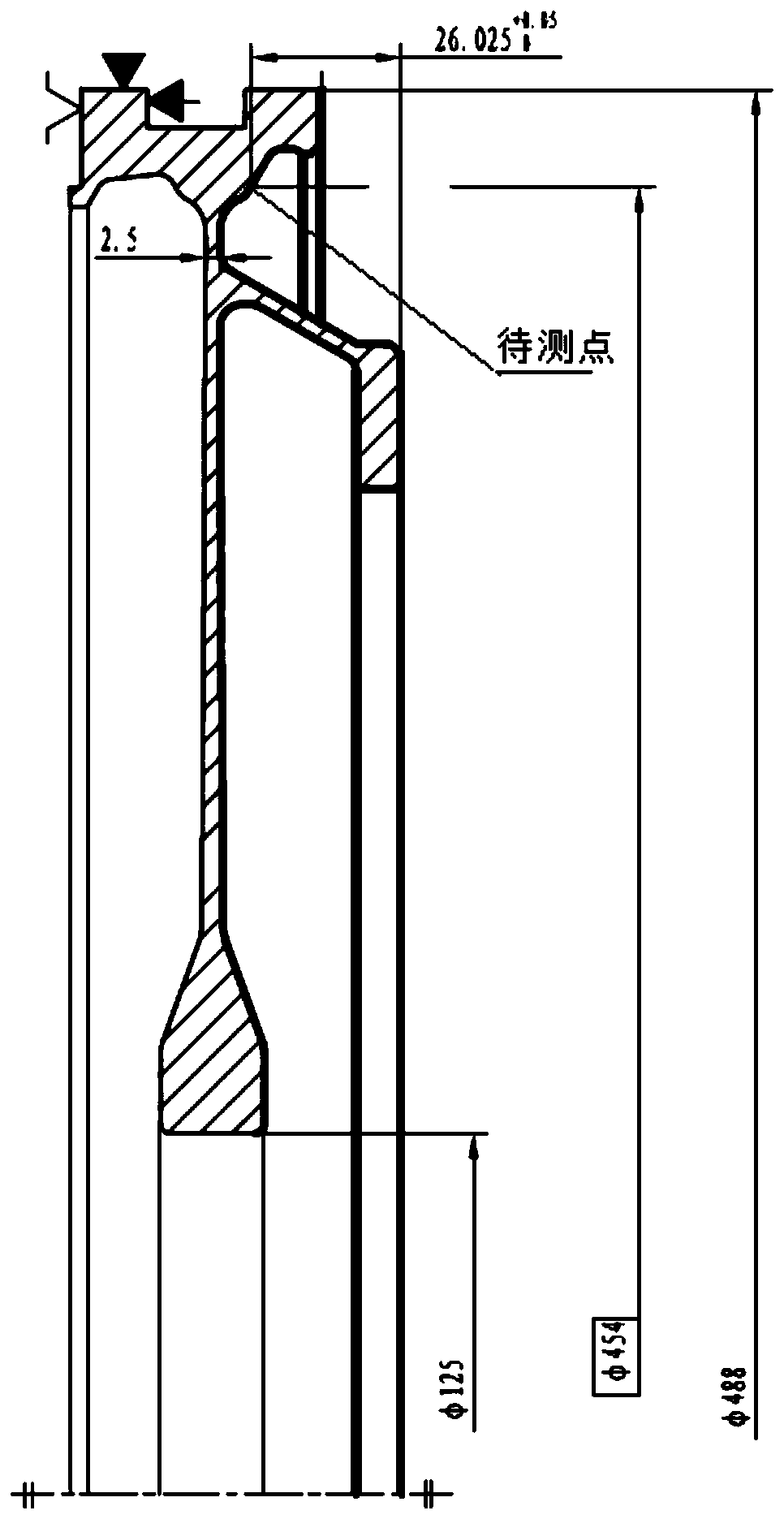

[0019] Such as figure 1 As shown, it is a high-pressure compressor disc part. Due to the large structural size of the part, the outer circle size of the part is The size of the inner hole is The thinnest part wall thickness is only 2.5mm. upper web There is a point with a depth reading of 26.025 on the inclined surface. Before the special measuring tool arrives, the depth of this point cannot be detected on the machine tool. If the part is disassembled and sent for three-coordinate detection, it will cause the part to be deformed in secondary clamping. It is a difficult point to detect the depth of the point on the slope on the machine tool.

[0020] In order to solve this difficulty, combined with the characteristics of CNC machine tools and dial indicator or dial indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com