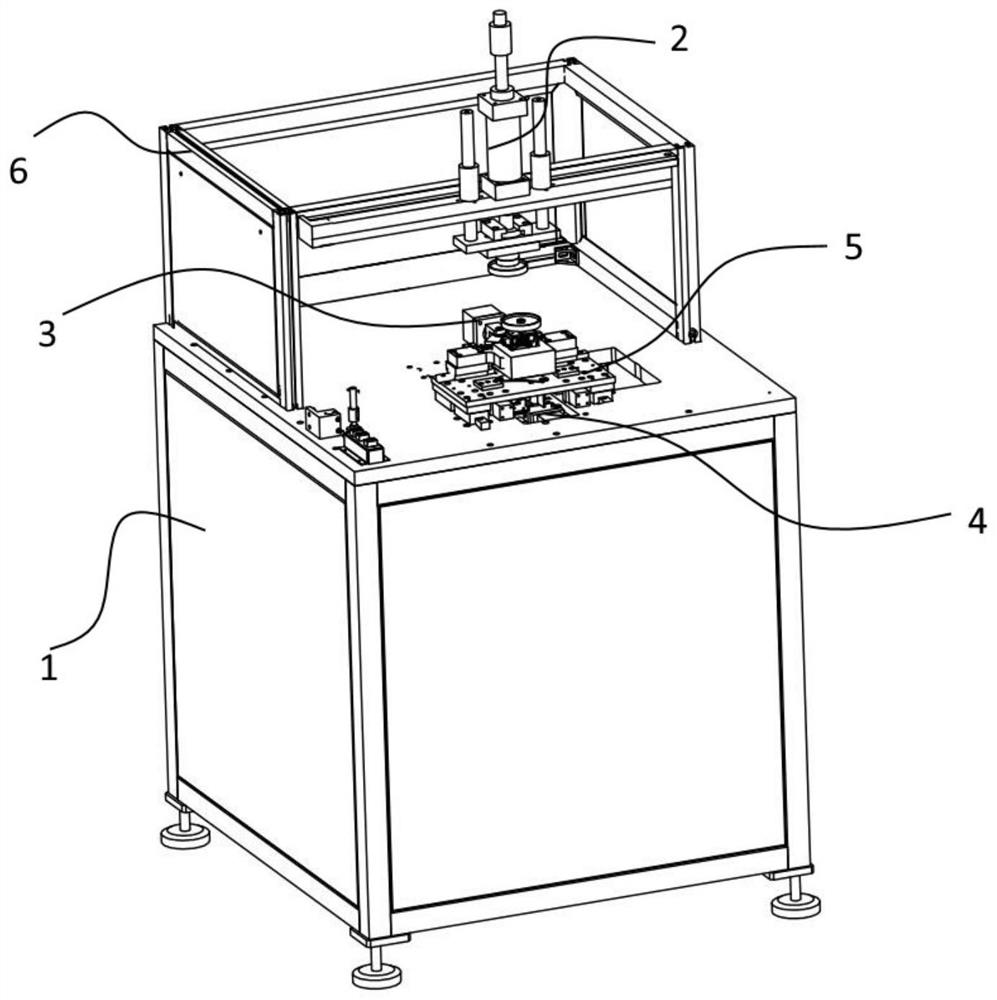

Noise detection device used for motor load and work method thereof

A detection device and noise technology, which is used in measuring devices, workpiece clamping devices, manufacturing tools, etc., can solve the problems of motor detection device collision, noise, and high motor repair rate, and achieve the effect of reducing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

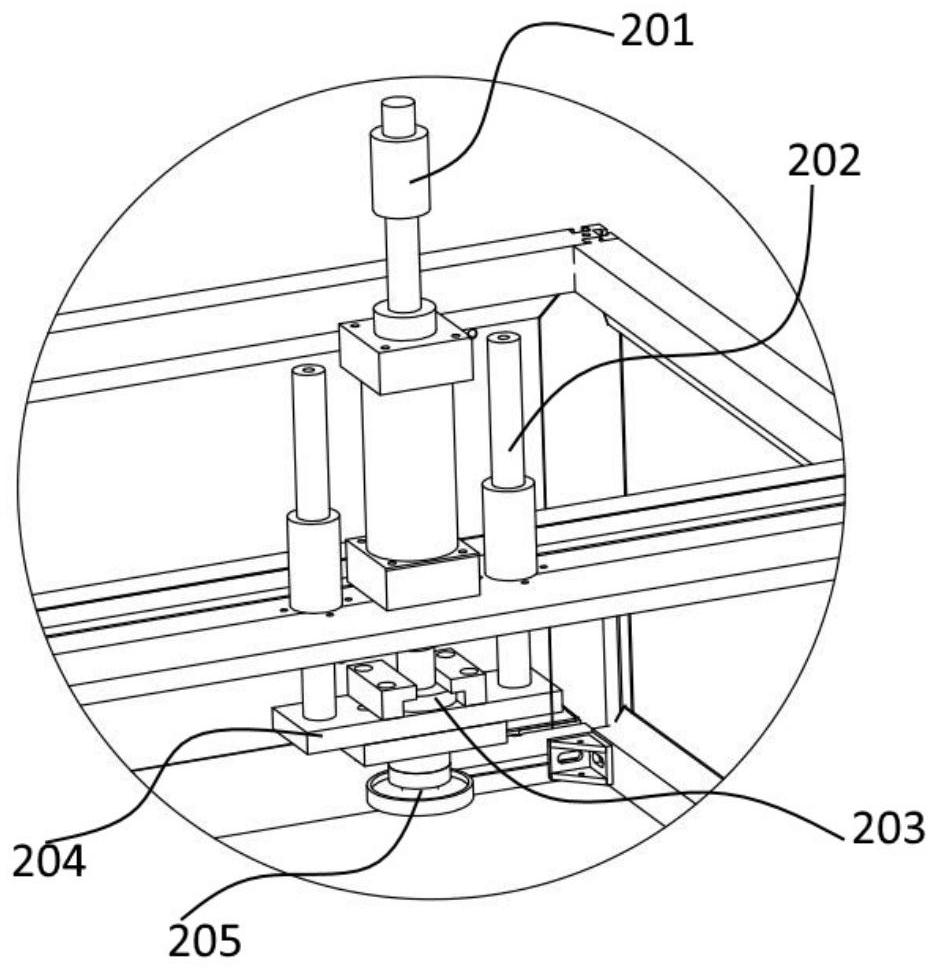

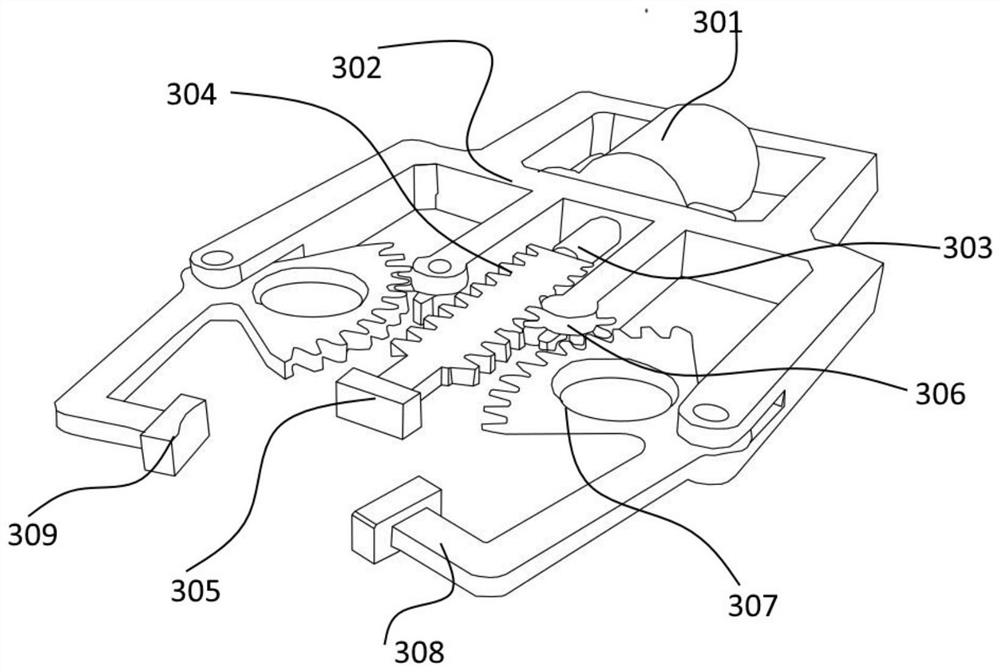

[0034] After the applicant's research and analysis, the reason for this problem (the offset motor will collide with the detection device to generate new noise, which will cause inaccurate detection results when the detection device is performing detection work) is that the existing During the noise detection process of the noise detection device, the motor will shift to a certain extent, and then the shifted motor will collide with the detection device to generate new noise, which will make the repair rate of the motor too high and increase the work of the operator Burden, in order to reduce the offset of the motor in the detection process, the present invention is further equipped with a clamping assembly to place the motor in a predetermined area of the device. At this time, the clamping motor starts to work, and the moving clamping motor can drive the transmission The shaft starts to work. At this time, the moving transmission shaft drives the transmission rack set on it t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com