Horizontal well cable protection device and application method

A cable protection and horizontal well technology, which is used in the installation of cables, the arrangement of cables between relative moving parts, electrical components, etc. problems, to achieve rapid positioning and installation, prevent contact friction, and ensure the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

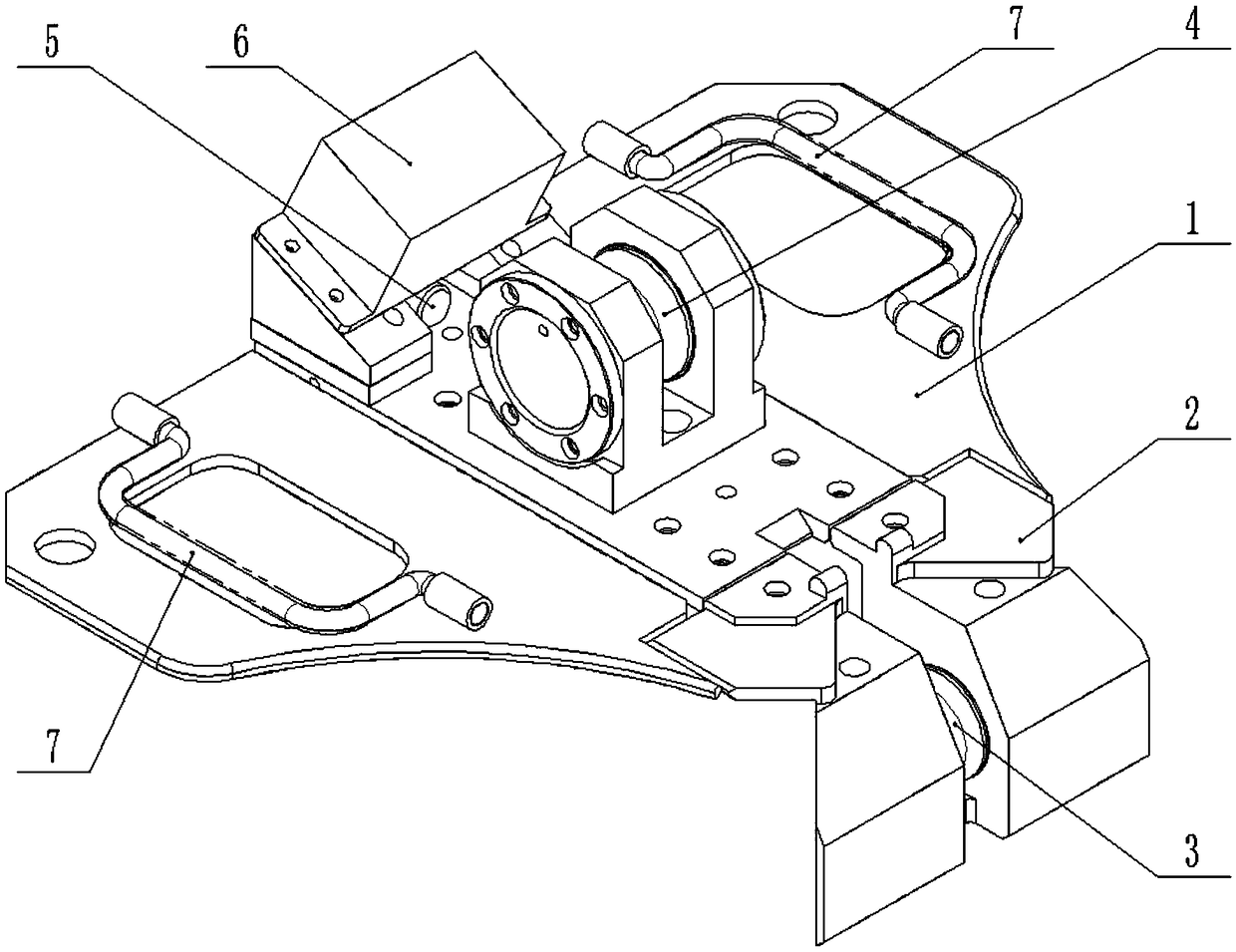

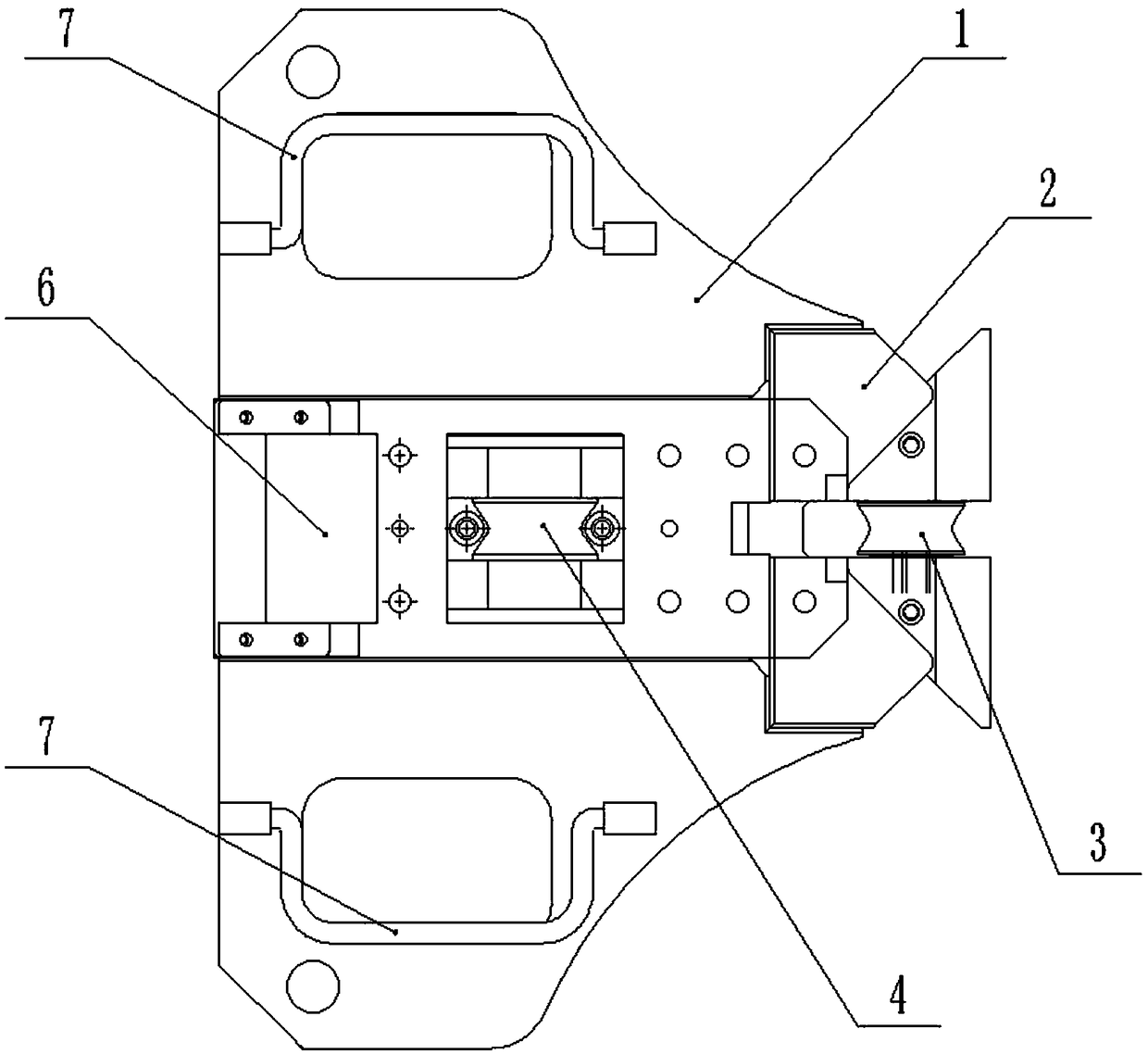

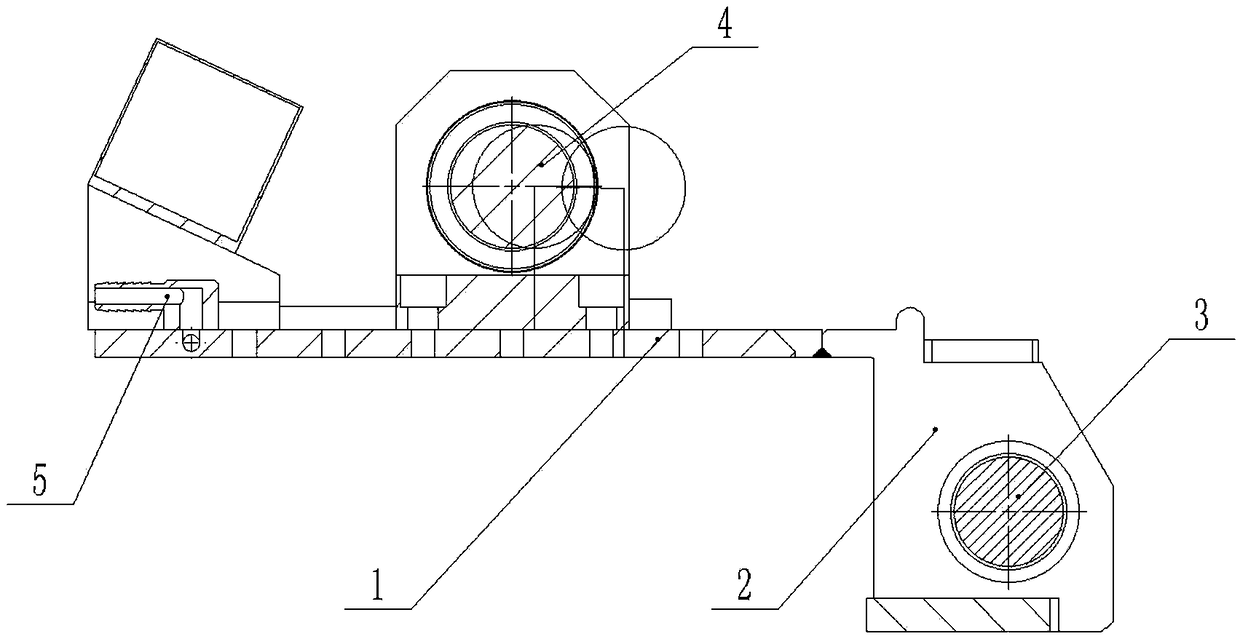

[0025] Combine below figure 1 , 2 , 3, 4 illustrate the present embodiment, a kind of horizontal well cable protection device, comprises the pulley frame 1 outside the well, the pulley frame 2 in the well, the pulley 3 in the well and the pulley 4 outside the well, the pulley frame 1 outside the well and the pulley frame 2 in the well Fixedly connected, the lower end of the pulley frame 2 in the well is a triangular structure cooperating with the corners of the wellhead, the pulley 3 in the well is connected to the pulley frame 2 in the well in rotation, and the pulley 4 outside the well is connected to the pulley frame outside the well in rotation 1. When in use, one end of the cable is connected to the traction device, and the other end of the cable extends into the well. The middle end of the cable is rolled and guided through the pulley 3 inside the well and the pulley 4 outside the well. This can not only avoid friction between the cable and the well wall, but also pass t...

specific Embodiment approach 2

[0026] Combine below figure 1 , 2 , 3, and 4 illustrate this embodiment, and this embodiment will further explain Embodiment 1. The two ends of the upper end surface of the pulley frame 1 outside the well are rotatably connected with a lifting handle 7, and the horizontal well cable protection device can be rotated to Vertical to the pulley frame 1 outside the well, when the lifting handle 7 is not in use, it can be rotated to fit with the pulley frame 1 outside the well.

specific Embodiment approach 3

[0027] Combine below figure 1 , 2 , 3, and 4 illustrate this embodiment, and this embodiment will further illustrate Embodiment 1. The left end of the outer pulley frame 1 is fixedly connected to a magnetic marker 6, and the magnetic marker 6, the inner pulley 3 and the outer pulley 4 In order to facilitate the measurement of the cable length, the connection of the downhole cable is usually equipped with an induction device for detecting the change of the electromagnetic signal. When the cable passes through the magnetic marker 6, the electromagnetic pulse changes, and the cable length is realized by capturing the electromagnetic pulse. The measurement; this part is the usual method for downhole cable length measurement, and the detection principle is the well-known electromagnetic induction principle, so this manual does not explain too much about the device model and principle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com