Stew pre-packaging container structure with bottle cap easy to open

A pre-packaging and easy-opening technology, applied in the field of stewed soup pre-packing containers, can solve the problems of difficult to open bottle caps, no sealed containers are found, etc., and achieve the effects of good safety and stability, good product labeling, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

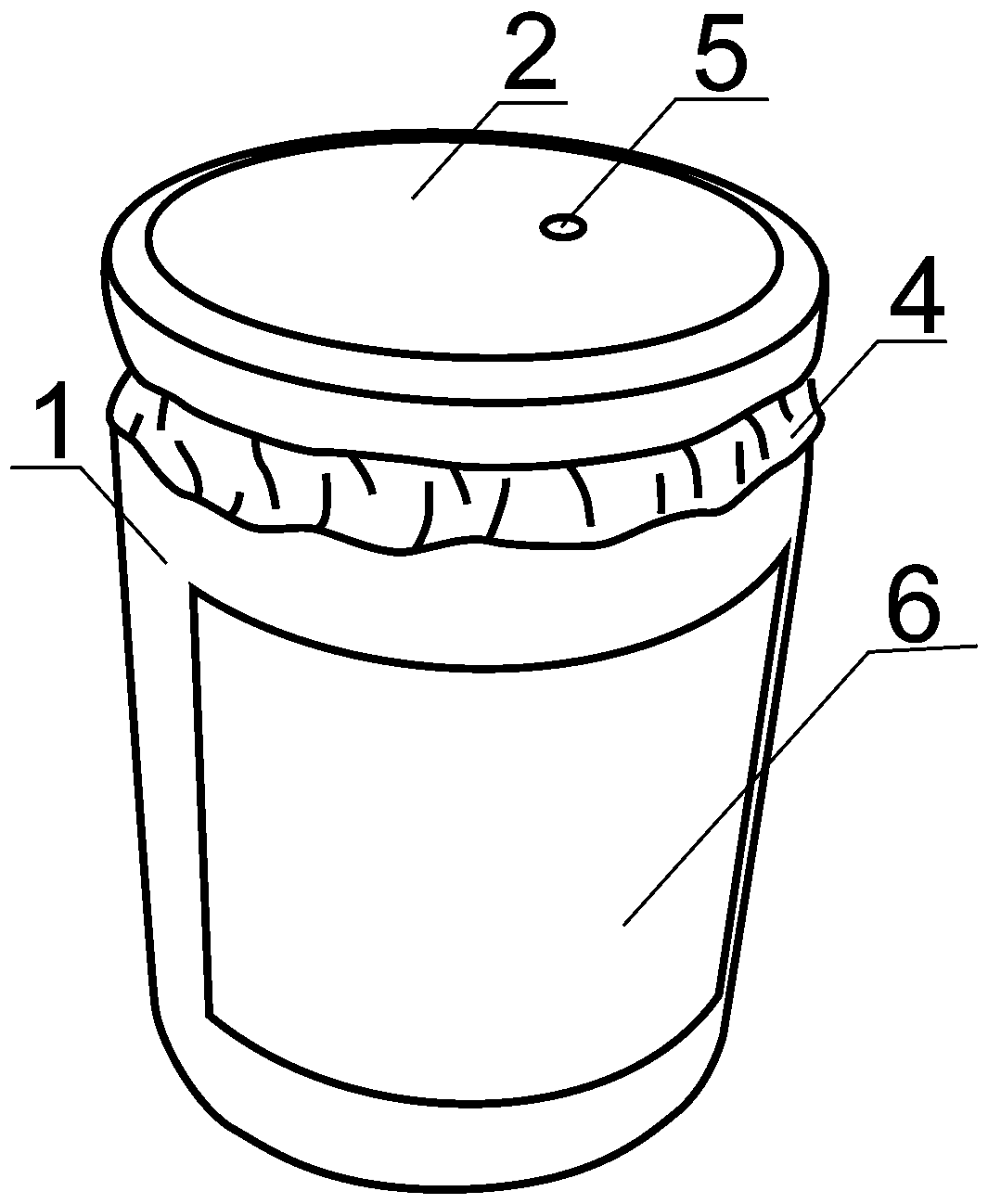

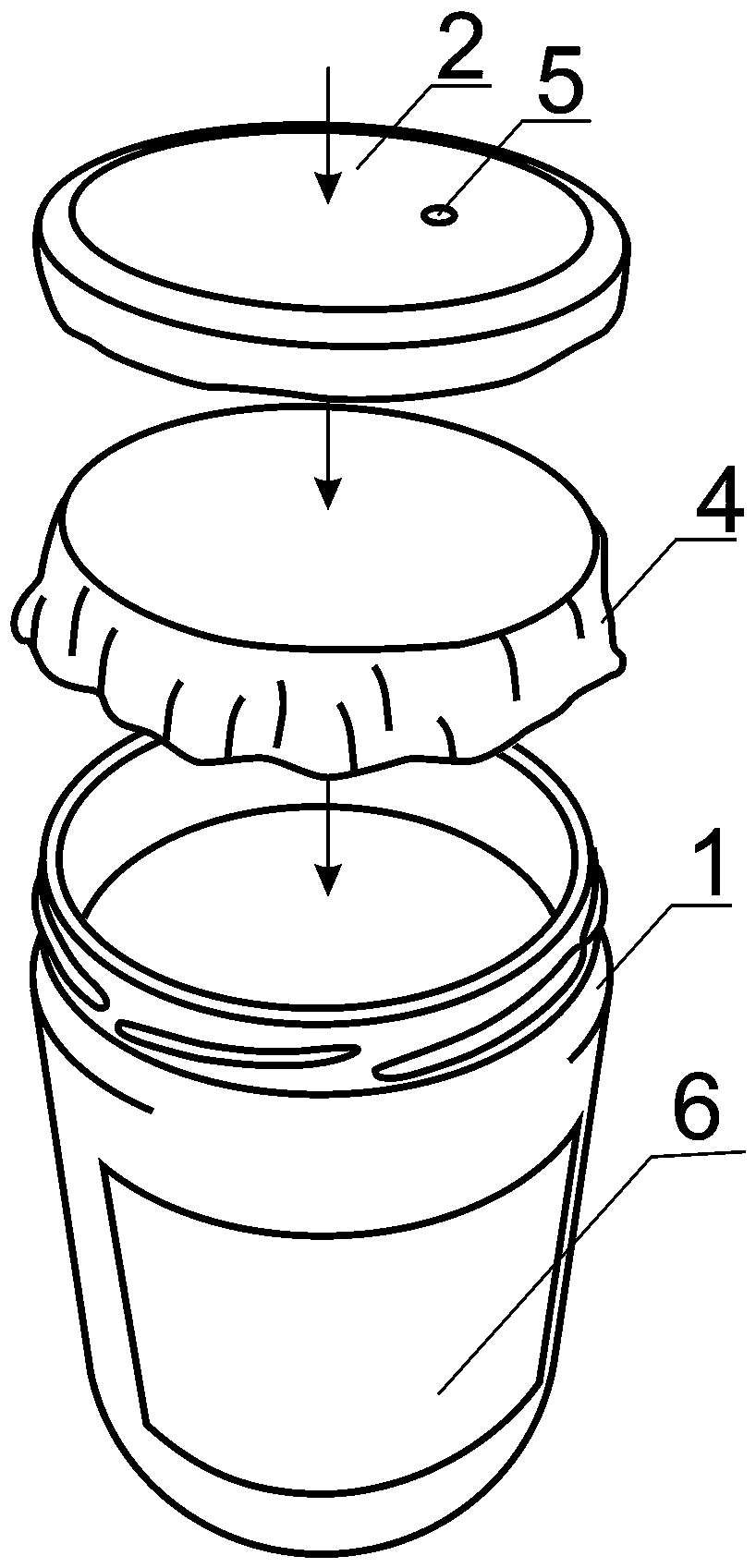

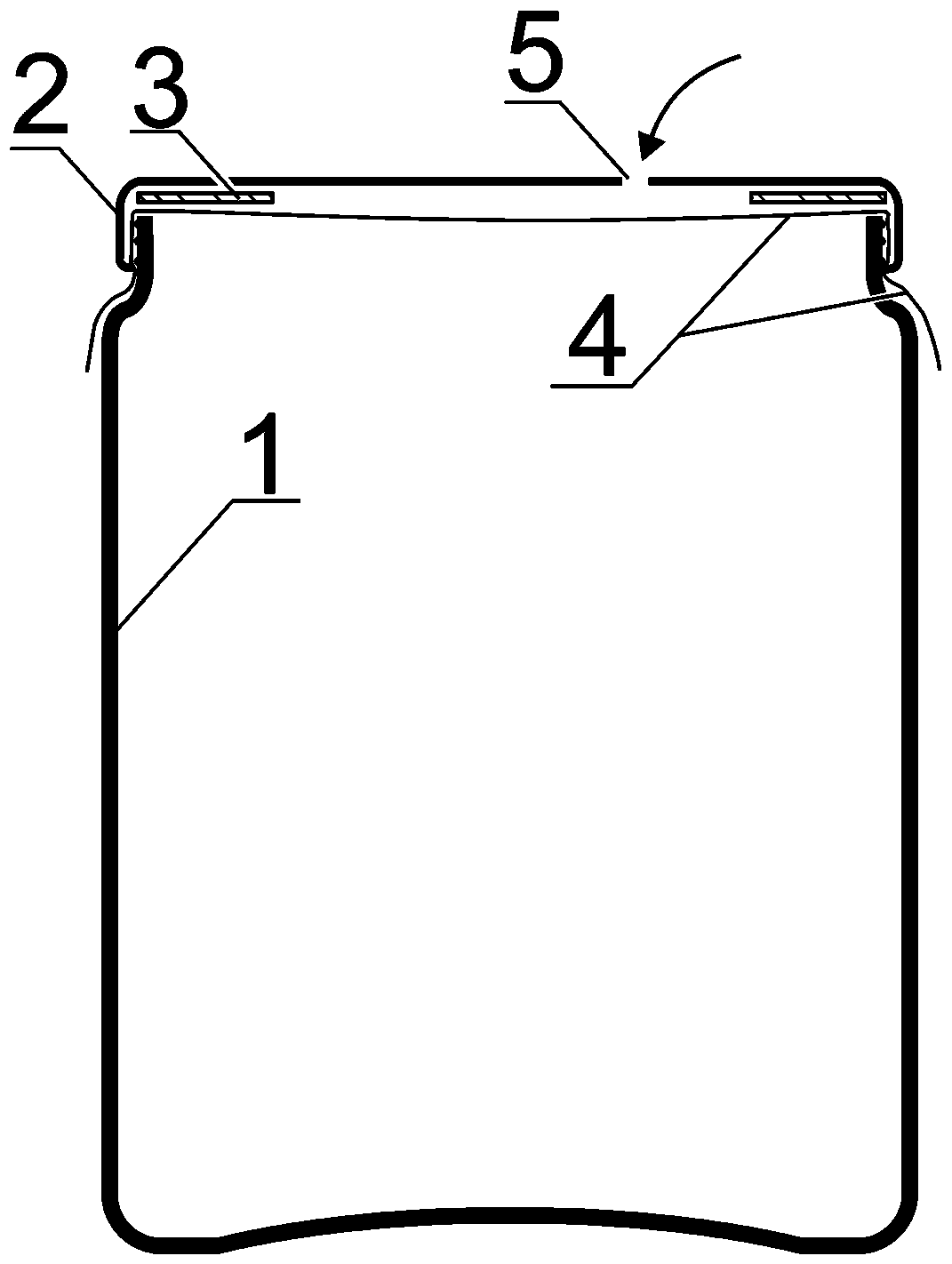

[0019] Such as figure 1 , 2 , 3, the easy-open type stewed soup prepackaging container structure of the present invention comprises wide-mouth glass bottle 1 and matching bottle cap 2 thereof, the metal foil 4 of food use, and bottle cap 2 comprises corresponding wide-mouth glass bottle 1 The elastic gasket 3 on the entire edge of the bottle mouth; the bottle cap 2 is provided with an opening 5 penetrating the bottle cap 2 in the inner range of the bottle mouth corresponding to the wide-mouth glass bottle 1; the bottle cap 2 is tightly sealed in the bottle of the wide-mouth glass bottle 1 The metal foil 4 is sandwiched between the bottle cap 2 and the bottle mouth of the wide-mouth glass bottle 1, the metal foil 4 is larger than and covers the bottle mouth of the wide-mouth glass bottle 1, and the metal foil 4 is visible outside the bottle cap 2.

[0020] Described wide-mouth glass bottle 1 is a wide-mouth glass bottle with a height of 12 cm and an opening of 8 cm; the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com